Preparation and application of hydroxyl modified poly-p-phenylene benzo imidazolinyl resin

A technology of benzodiimidazole and hydroxyterephthalic acid, which is applied in the field of preparation and application of a type of hydroxyl-modified polyparaphenylene benzodiimidazole resin, can solve the problems that mechanical properties are inferior to PBO, etc., and achieves improved compression. Strength and surface polarity, excellent heat and flame resistance, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Poly 1,4-(2,5-dihydroxy)phenylene-2,6-benzodiimidazole new resin (PDBI) prepares (1,2,4,5-tetraaminobenzene hydrochloride Mixed polycondensation with 2,5-dihydroxyterephthalic acid)

[0057] Add P sequentially into the glass polymerization reactor 2 o 5 6.0g and P 2 o 5 18.0g (PPA) of polyphosphoric acid with a mass concentration of 80% was heated up to 100°C and stirred for 1 hour until it became clear and transparent to form a polyphosphoric acid containing 85.0% PPA. 2 o 5 Add 1.57 g (0.0055 mol) of 1,2,4,5-tetraaminobenzene hydrochloride (TAB 4HCl) after passing through nitrogen for a little cooling, heat up to 100°C, stir to remove HCl gas for 5 hours, and turn pink Opaque solution, add 1.1g (0.0055mol) of 2,5-dihydroxyterephthalic acid (2,5-DHTA) at this time, the mass percentage concentration (ω) of two monomers TAB 4HCl and 2,5-DHTA 10.0% (corresponding to the molar concentration of monomer 0.023mol / 100g PPA), it turns into a yellow turbid li...

Embodiment 2

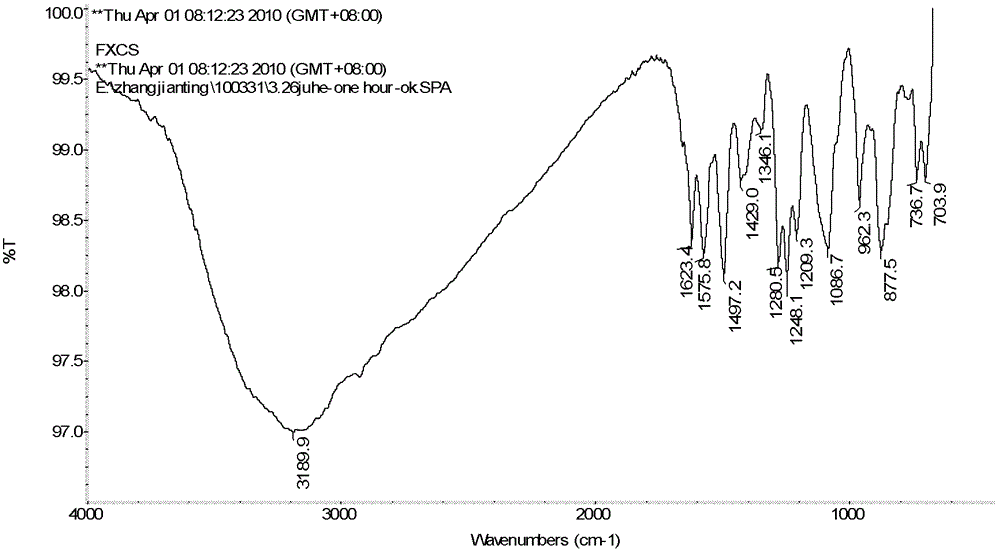

[0058] PDBI resin infrared see figure 1 , the relevant characteristic peaks and their attribution analysis are: 1623.4 (s) imidazole C=N peak, 1575.8 (s) benzene ring C=C peak, 197.2 (s) heterocycle absorption, 1429.0, 1248.1, 1086.7 (s) benzene ring C-C Skeleton peak, 1346.1 (s) C-N peak of imidazole, 877.5, 736.7 (s) C-H on benzene ring. In addition, in this batch there is also free state OH-. Due to the effect of intramolecular hydrogen bonds, the stretching vibration peak of -OH moves to a lower wave number and becomes wider, which is 3189.9 (s). According to thermogravimetric analysis, the temperature at 10% weight loss is 550°C, and the temperature corresponding to the maximum decomposition rate is 665.12°C. Embodiment 2PDBI as-spun fiber (the application of resin-the direct wire-drawing method of the PPA liquid crystal stock solution of new resin PDBI)

[0059] The same as the operation of preparing PDBI by polycondensation reaction in Example 1, the PDBI resin liquid...

Embodiment 3

[0061] The condition scope of embodiment 3PDBI new resin preparation and application

[0062] On the basis that the molar ratio of TAB 4HCl and DHTA is 1:1, change the monomer molar concentration C (mol / 100g PPA), reaction temperature T (℃) and reaction time t (h) in Example 1, according to the example The operation steps of 1 were used to prepare new PDBI resins under different process conditions. First, the method of obtaining primary fibers in Example 2 was used to take out part of the PDBI monofilament fibers and measure their tensile strength, and then the remaining PDBI resin liquid crystal stock solution was prepared according to Example 1. The PDBI resin was obtained by water washing, post-neutralization treatment and drying, and its intrinsic viscosity was measured. The results are shown in Table 1.

[0063] Table 1 Properties of PDBI resin and PDBI monofilament fiber

[0064]

[0065] *Total yield including removal of PDBI monofilament fibers

[0066] **The concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com