Snowflake yarn and manufacturing method thereof

A manufacturing method and yarn technology, applied in the field of snowflake yarn and its manufacturing, can solve problems such as cleaning difficulties, losses, and increased product costs, and achieve the effects of improving the efficiency of the weaving process, increasing the strength of the yarn, and smoothing the sliver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

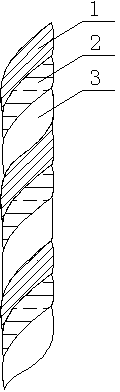

[0024] reference figure 1 , A snowflake yarn, the yarn body includes a pure polyester yarn bundle 1, a mixed yarn bundle 2 and a combed cotton yarn bundle 3, the pure polyester yarn bundle 1, a mixed yarn bundle 2 and a combed cotton yarn bundle 3 in a spiral The mixed yarn bundle 2 is formed by mixing cotton and reused cotton.

Embodiment 2

[0026] On the basis of Example 1, the preferred solution of the present invention is: the weight percentage of the pure polyester yarn bundle 1, the mixed yarn bundle 2 and the combed cotton yarn bundle 3 is 40:30:30, and the yarn count is 30s in English. The weight ratio of cotton and reused cotton in mixed yarn bundle 2 is 50:50.

Embodiment 3

[0028] On the basis of embodiment 1 or 2, this embodiment provides a method for manufacturing snowflake yarn, including the following process flow: polyester warp blown, carded, draw, roving; cotton / recycled cotton warp blown, Carding, drawing, roving; raw cotton is blown, carded and / or pre-drawing and combed, drawing, roving, and then three rovings of polyester, cotton / recycled cotton and raw cotton are fed together by spinning It is spun into yarn, and then made into finished products by warp and winding; among them: cotton / re-used cotton blend is processed into roving that meets the technological requirements and fed normally from the spinning frame, and at the same time, the two sides of the roving are fed separately after the middle roller of the spinning frame One pure polyester roving and one combed cotton roving can be processed into snowflake yarn after being drafted and twisted in the spinning drafting zone by the processing method of Siro spinning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com