High-weather-resistance aluminum alloy wood grain profile and preparation method thereof

A technology for aluminum alloys and aluminum profiles, applied in powder coatings, coatings, polyester coatings, etc., can solve the problems of mechanical strength loss, easy fading aging, fading gloss, etc., to enhance weather resistance, delay fading and aging, wood feeling realistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

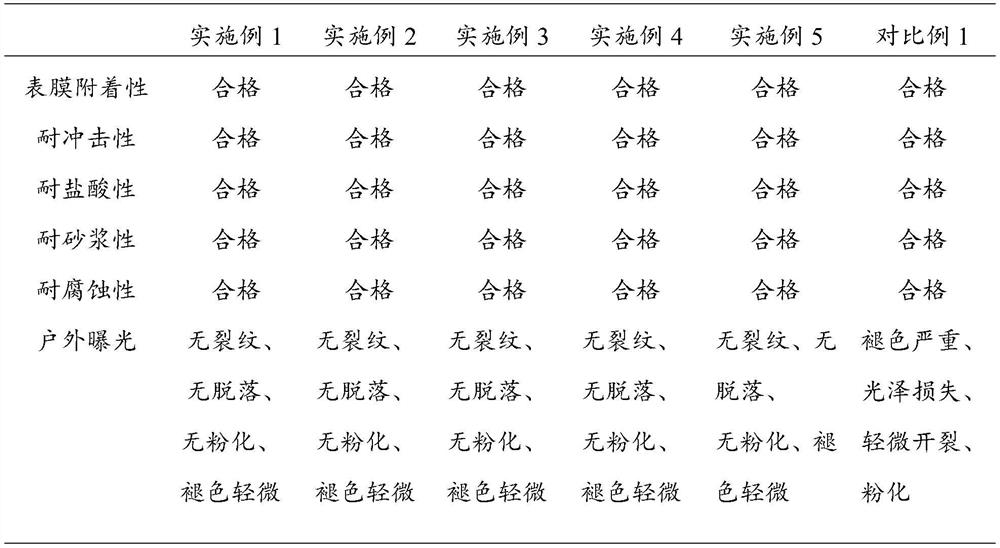

Examples

preparation example Construction

[0069] Correspondingly, the present invention also provides a method for preparing the above-mentioned high-weather-resistant aluminum alloy wood grain profile, comprising the following steps:

[0070] S1: Clean the surface of the aluminum profile substrate, then perform passivation pretreatment and dry it;

[0071] S2: spray a high-weather-resistant primer on the surface of the aluminum profile obtained in S1, and perform high-temperature curing to form a primer layer;

[0072] S3: Use weather-resistant wood grain transfer film to thermally transfer wood grain to the aluminum profile obtained in S2;

[0073] S4: Spray high weather-resistant protective coating on the surface of the transferred aluminum profile, and flash dry to obtain a protective coating to obtain a finished product.

[0074] The preparation method of the high-weather-resistant aluminum alloy wood grain profile provided by the present invention has the advantages of simple process and reasonable process, and...

Embodiment 1

[0106] High weather-resistant aluminum alloy wood grain profiles:

[0107] The surface of the high-weather-resistant aluminum alloy wood grain profile is sequentially provided with a base powder layer, a weather-resistant thermal transfer wood grain layer and a protective coating. The primer layer comprises polyester powder coating, the protective coating comprises room temperature curing FEVE fluorocarbon coating; the room temperature curing FEVE fluorocarbon coating comprises fluorocarbon resin, organic solvent, defoamer, dispersant, curing agent agent and antifouling agent, the fluorocarbon resin is ethylene-tetrafluoroethylene copolymer; the curing agent is aliphatic polyisocyanate.

[0108] The preparation method of the above-mentioned high weather-resistant aluminum alloy wood grain profile:

[0109] S1: The surface of the aluminum profile substrate is cleaned, then passivated with a chromate passivator, and then dried at 60° C. for 30 minutes.

[0110] S2: Spray a hig...

Embodiment 2

[0114] High weather-resistant aluminum alloy wood grain profiles:

[0115] The surface of the high-weather-resistant aluminum alloy wood grain profile is sequentially provided with a base powder layer, a weather-resistant thermal transfer wood grain layer and a protective coating. The primer layer comprises polyester powder coating, the protective coating comprises room temperature curing FEVE fluorocarbon coating; the room temperature curing FEVE fluorocarbon coating comprises fluorocarbon resin, organic solvent, defoamer, dispersant, curing agent agent and antifouling agent, the fluorocarbon resin is ethylene-tetrafluoroethylene copolymer; the curing agent is aliphatic polyisocyanate.

[0116] The preparation method of the above-mentioned high weather-resistant aluminum alloy wood grain profile:

[0117] S1: The surface of the aluminum profile substrate is cleaned, then passivated with a chromate passivator, and then dried at 90° C. for 10 minutes.

[0118] S2: Spray a hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com