Oil-repellent thermosetting powder coating and preparation method and application thereof

A powder coating and thermosetting technology, applied in powder coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems that thermosetting powder coatings have not been developed, and achieve excellent thermal oxidation stability and corrosion resistance Good, excellent chemical resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Silicone resin 10 parts

[0051] Thermosetting fluorocarbon resin 6 parts

[0052] Curing agent 12 parts

[0053] Leveling agent 1 part

[0054] Degasser 0.5 part

[0055] 26.5 parts of pigments and fillers

[0056] Matting agent 2 parts

[0057] 2. Preparation of oil-repellent thermosetting powder coating:

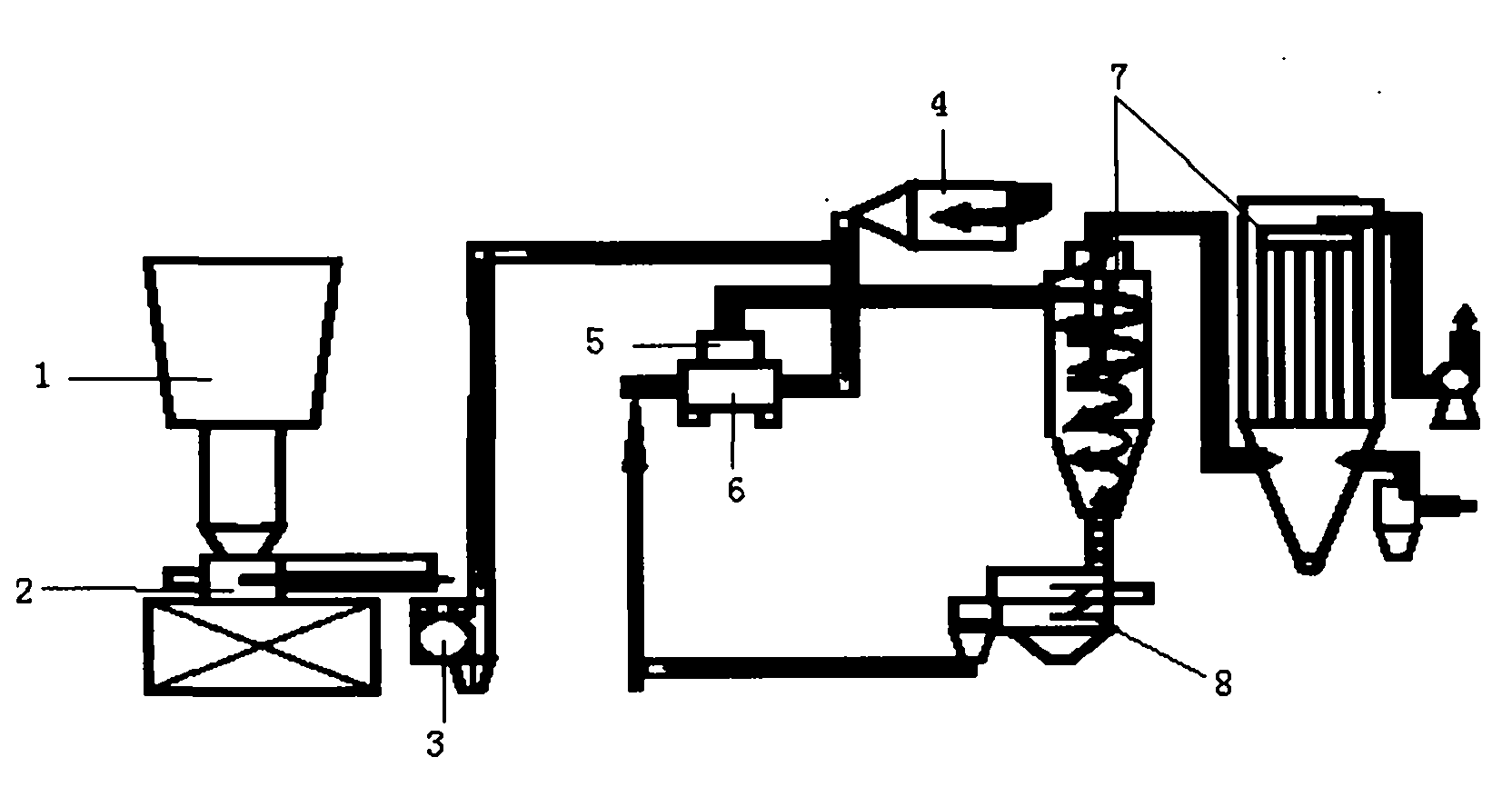

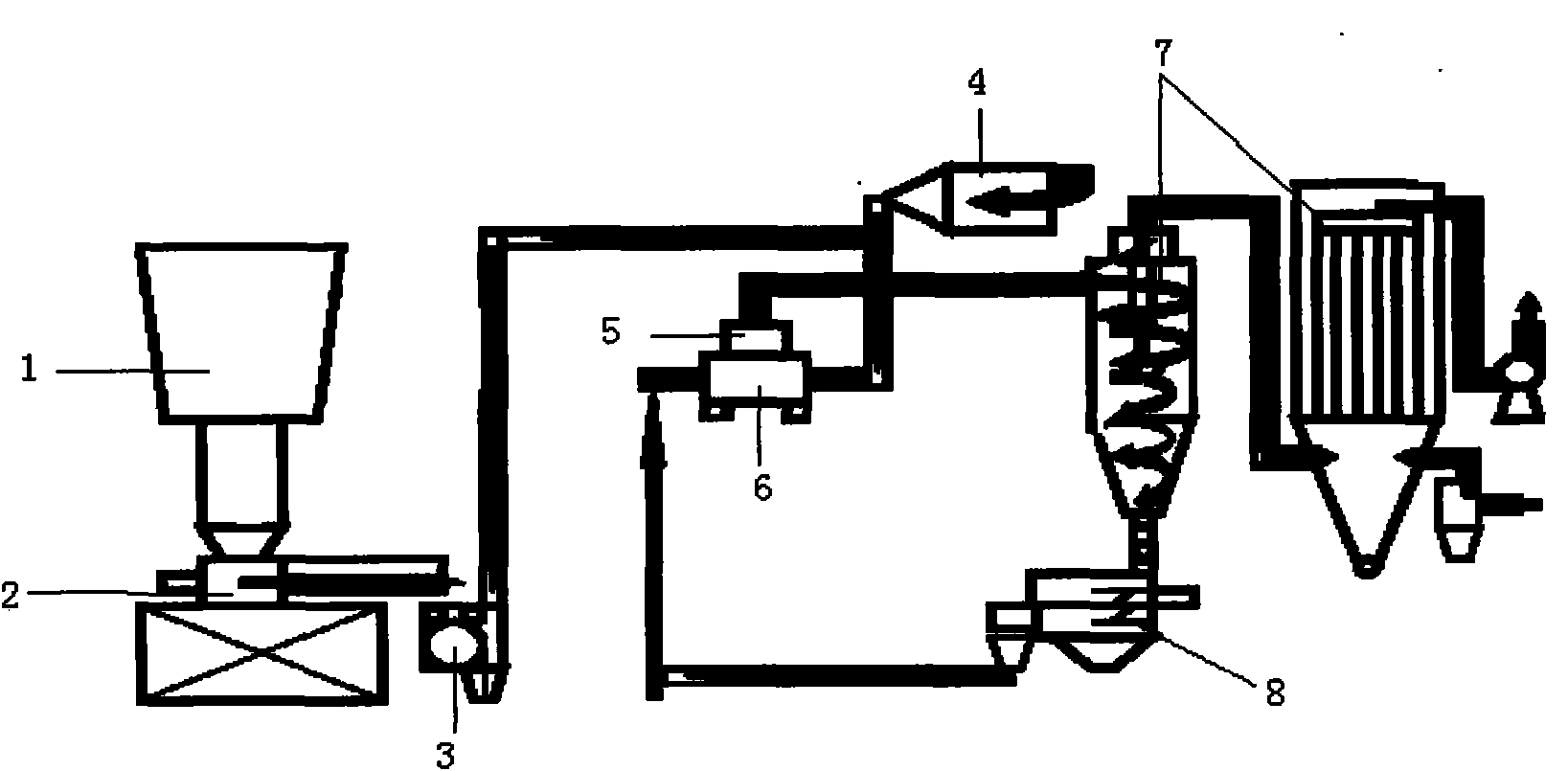

[0058] 1. Select acrylic resin, silicone resin, thermosetting fluorocarbon resin, curing agent, leveling agent, degasser, pigment and filler and matting agent in the mixing tank (1) according to the parts by weight described in the above 1, and then After being co-extruded by the extruder (2), it is cooled by the blower fan (3), and the cold air can also be conveyed by the heat exchanger (4) for further cooling to obtain a tablet material;

[0059] ②Take the tabletting material obtained in step ①, and use the auxiliary mill (5) to preliminarily grind to obtain a coarse powder, and then use the main mill (6) to pulverize and grind for a second time to obtain a...

Embodiment 2

[0072] 5 parts silicone resin

[0073] Thermosetting fluorocarbon resin 8 parts

[0074] Hydroxy polyester resin 25 parts

[0075] Isocyanate curing agent 12 parts

[0076] Leveling agent 1 part

[0077] Degasser 0.5 part

[0078] 26.5 parts of pigments and fillers

[0079] Matting agent 2 parts

[0080] 2. Preparation of oil-repellent thermosetting powder coating:

[0081] ① Select acrylic resin, silicone resin, thermosetting fluorocarbon resin, hydroxyl polyester resin, isocyanate curing agent, leveling agent, degassing agent, pigment filler and matting agent into the mixing tank according to the parts by weight described in 1 above (1), then pass through extruder (2) co-extrusion, then pass through fan (3) cooling, also can use heat exchanger (4) to transport cold air for further cooling, to obtain tablet material;

[0082] ②Take the tabletting material obtained in step ①, and use the auxiliary mill (5) to preliminarily grind to obtain a coarse powder, and then use t...

Embodiment 3

[0095] Silicone resin 10 parts

[0096] Hydroxy polyester resin 23 parts

[0097] 12 parts of epoxy resin curing agent

[0098] Leveling agent 1 part

[0099] Degasser 0.5 part

[0100] 26.5 parts of pigments and fillers

[0101] Matting agent 1 part

[0102] Curing catalyst 1 part

[0103] 2. Preparation of oil-repellent thermosetting powder coating:

[0104] ① Select acrylic resin, silicone resin, hydroxyl polyester resin, epoxy resin curing agent, leveling agent, degassing agent, pigments and fillers, matting agent and curing catalyst according to the parts by weight described in the above 1 and put them into the mixing tank (1), then pass through extruder (2) co-extrusion, then pass through fan (3) cooling, also can use heat exchanger (4) to transport cold air for further cooling, to obtain tablet material;

[0105] ②Take the tabletting material obtained in step ①, and use the auxiliary mill (5) to preliminarily grind to obtain a coarse powder, and then use the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com