Easy-to-clean fluorocarbon paint and preparation method thereof

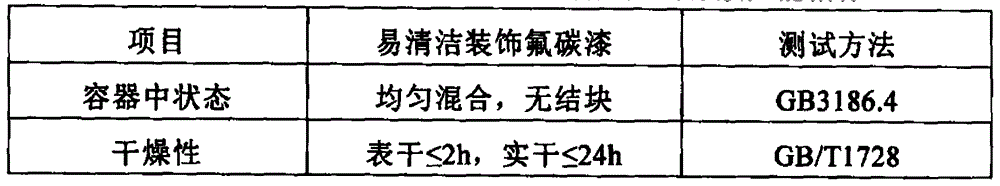

A fluorocarbon paint, easy-to-clean technology, applied in the direction of coating, can solve the problems of affecting the decorative effect, loss of color, low surface energy, etc., to achieve good gloss and color retention performance, smooth and flat appearance, good easy-to-clean performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

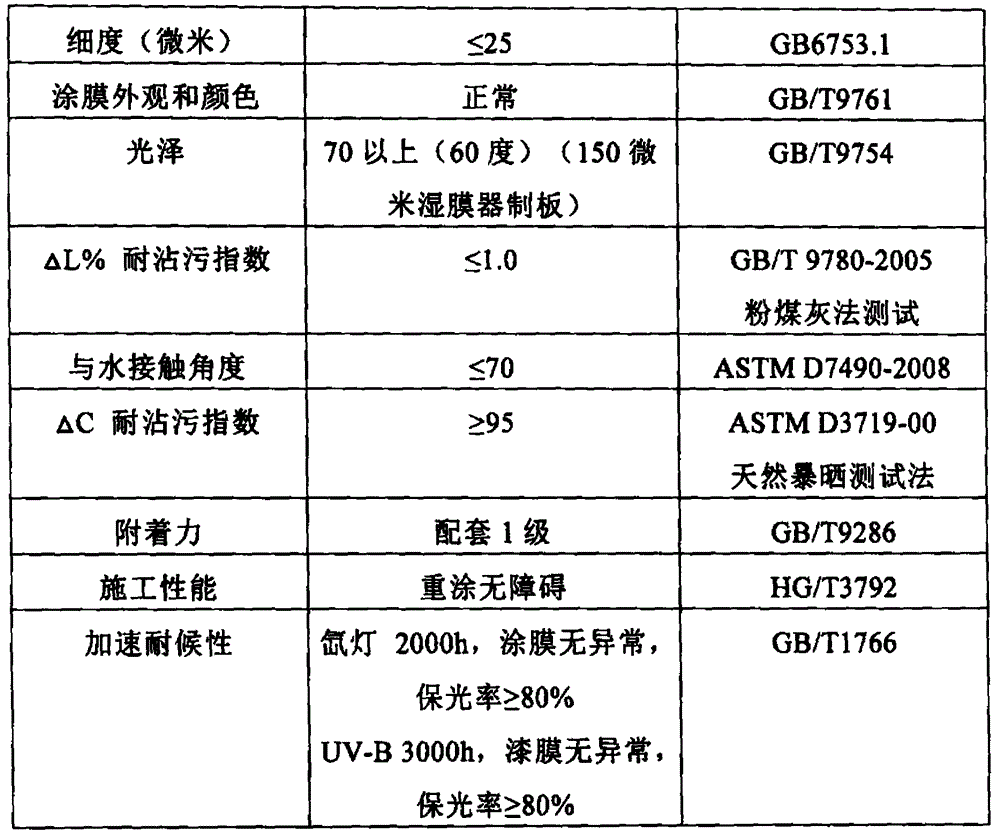

Embodiment 1

[0033] 40g of trifluoroethyl acrylate polymer, 10g of aliphatic polycyanate, 16g of mixed solvent (isophorone, xylene and propylene glycol methyl ether acetate), 30g of pigment, 3g of matting powder (fumed silica), Additives 0.5g (including leveling agent Levaslip 435, defoamer Deform 6600).

[0034] The method for preparing above-mentioned coating comprises the following process steps:

[0035] (1) All fluorocarbon resins 40g, isophorone 5g, xylene 5g and propylene glycol methyl ether acetate 6g are put into the reaction kettle as a mixed solvent according to the formula requirements, and stirred;

[0036] (2) Keep stirring and add 0.2g of leveling agent Levaslip 435 as additive and 30g of iron oxide as pigment into the reaction kettle in turn, and stir for 0.5 to 1 hour;

[0037] (3) pass through the grinder after being mixed uniformly, and the particle size reaches 5 microns;

[0038] (4) Add 0.3g of defoamer Deform 6600 and 3g of matting powder as the remaining additives...

Embodiment 2

[0048] 55g of trifluoroethyl methacrylate polymer, 15g of urea-formaldehyde resin (UF), 10g of mixed solvent, 5g of pigment, 0g of matting powder, and 1g of auxiliary agent.

[0049] Described mixed solvent comprises butyl acetate, cyclohexanone, propylene glycol methyl ether acetate.

[0050] The method for preparing above-mentioned coating comprises the following process steps:

[0051] (1) 45g of fluorocarbon resin, 2g of butyl acetate, 2g of cyclohexanone, and 6g of propylene glycol methyl ether acetate are mixed into the reaction kettle as required by the formula, and stirred;

[0052] (2) Keep stirring and put 0.3g of dispersant Disponer 903, 1g of titanium dioxide, 1g of cyanine blue and 3g of cyanine green into the reaction kettle in turn, and stir for 0.5 to 1 hour;

[0053] (3) pass through the grinder after being mixed uniformly, and the particle size reaches 30 microns;

[0054] (4) Add 0.2g of dispersant Disponer 903 and 10g of fluorocarbon resin as the remaining ...

Embodiment 3

[0059] Pentafluoropropyl acrylate polymer 45g, melamine formaldehyde resin (MF) 10g, mixed solvent 15g, pigment 15g, matting powder 2g, auxiliary agent 0.8g.

[0060] Described mixed solvent comprises cyclohexanone, xylene, propylene glycol methyl ether acetate.

[0061] The method for preparing above-mentioned coating comprises the following process steps:

[0062] (1) Part of the fluorocarbon resin 25g, cyclohexanone 10g, xylene 2g, propylene glycol methyl ether acetate 3g mixed solvent is put into the reactor according to the formula requirements, and stirred;

[0063] (2) Keep stirring and put 0.2g of leveling agent Levaslip 882, 0.2g of defoamer Deform 5500, 0.1g of dispersant Disponer983, and 15g of carbon black into the reaction kettle in turn, and stir for 0.5 to 1 hour;

[0064] (3) pass through the grinder after being mixed evenly, and the particle size reaches 20 microns;

[0065] (4) Add the remaining additives, 0.1g leveling agent Levaslip 882, 0.1g defoamer Def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mixed viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com