High-hardness fingerprint-resistant coating and preparation method thereof

A fingerprint-resistant, high-hardness technology, applied in coatings and other directions, can solve problems such as harm to the human body, affecting the life of welding parts, and producing zinc mist, etc., to achieve the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

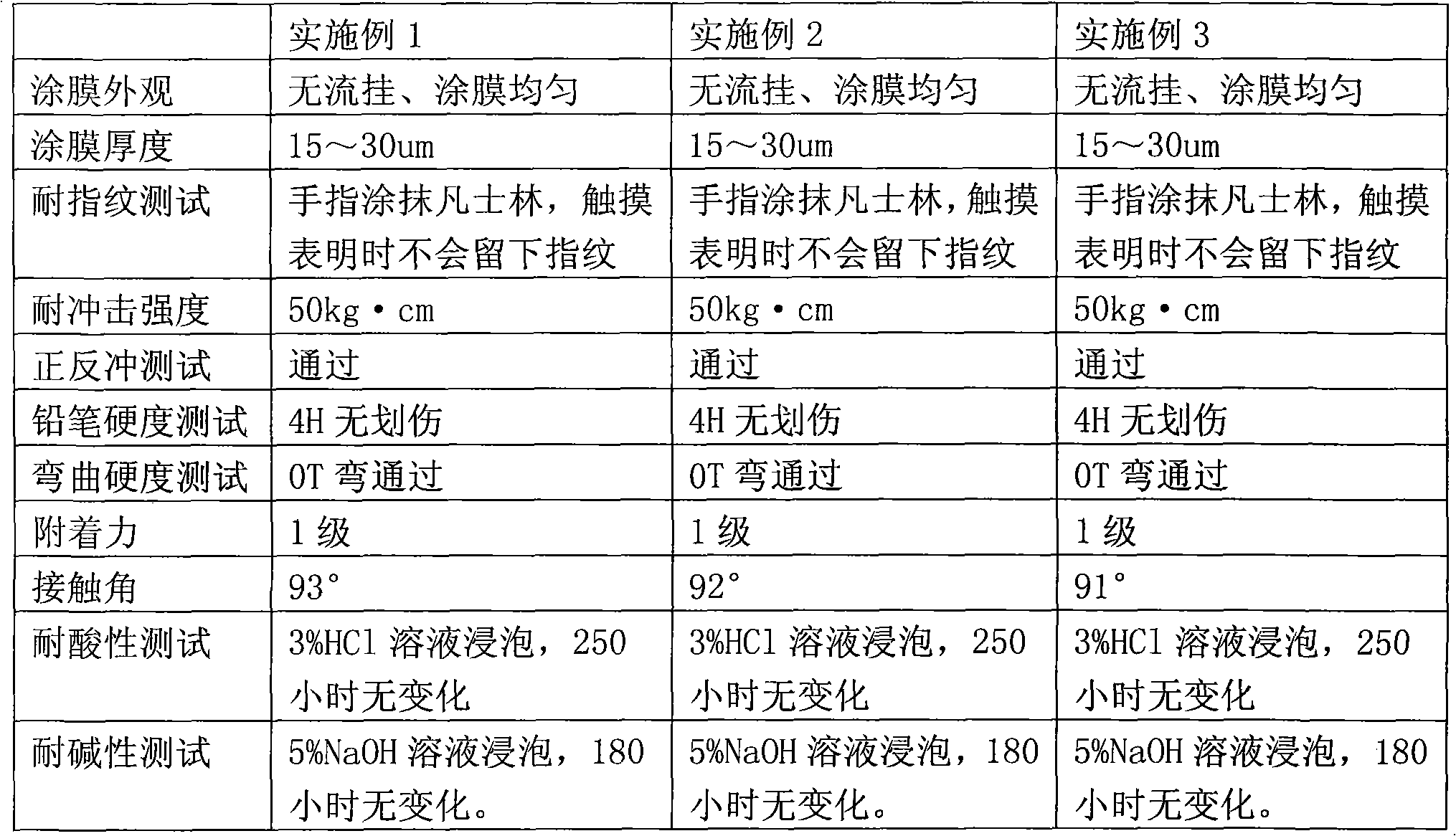

Examples

Embodiment 1

[0031] A high-hardness anti-fingerprint paint, including solvent, fluorocarbon resin, amino resin, nano-silica, nano-titanium dioxide, polytetrafluoroethylene, polyethylene wax and additives, wherein the solvent is butyl acetate, DBE and xylene Mixture, additives are dispersant, leveling agent and defoamer. By weight percentage, the content of each component is as follows:

[0032] Fluorocarbon resin 50%

[0033] Amino resin 10%

[0034] Nano Silica 10%

[0035] Nano Titanium Dioxide 5%

[0036] PTFE 5%

[0037] Polyethylene wax 3%

[0038] Butyl acetate 5%

[0039] DBE 5%

[0040] Xylene 5%

[0041] Auxiliary 2%

[0042] Weigh each component of the above content, mix butyl acetate, DBE and xylene as a solvent; divide the solvent into two parts: the first part of solvent and the second part of solvent, and add nano-silica and nano-titanium dioxide to the first part Mix and stir in the solvent for 20 minutes to obtain the first solution, add the fluorocarbon resin to ...

Embodiment 2

[0044] A high-hardness anti-fingerprint paint, including solvent, fluorocarbon resin, amino resin, nano-silica, nano-zinc oxide, polytetrafluoroethylene, polyethylene wax and additives, wherein the solvent is isophorone and butyl acetate A mixture of benzene and dispersant, leveling agent and defoamer as additives. By weight percentage, the content of each component is as follows:

[0045] Fluorocarbon resin 55%

[0046] Amino resin 10%

[0047] Nano Silica 8%

[0048] Nano Zinc Oxide 2%

[0049] PTFE 5%

[0050] Polyethylene wax 4%

[0051] Isophorone 5%

[0052] Butyl acetate 5%

[0053] Benzene 4%

[0054] Auxiliary 2%

[0055] Weigh each component of the above content, mix isophorone, butyl acetate and benzene as a solvent; add fluorocarbon resin to the solvent and mix and stir for 13 minutes, then add nano-silica and nano-zinc oxide and mix and stir for 18 minutes Minutes to get a mixed solution; mix the mixed solution evenly at a speed of 2000 rpm, then add pol...

Embodiment 3

[0057]A high-hardness anti-fingerprint coating, including solvent, fluorocarbon resin, amino resin, nano-silica, nano-titanium dioxide, nano-zirconia, polytetrafluoroethylene, polyethylene wax and additives, wherein the solvent is butyl acetate, The mixture of propylene glycol methyl ether acetate, DBE and toluene, the auxiliary agent is dispersant, leveling agent and defoamer. By weight percentage, the content of each component is as follows:

[0058] Fluorocarbon resin 58%

[0059] Amino resin 11%

[0060] Nano Silica 5%

[0061] Nano Titanium Dioxide 5%

[0062] Nano Zirconium Dioxide 1%

[0063] PTFE 5%

[0064] Polyethylene wax 3%

[0065] Butyl acetate 5%

[0066] Propylene Glycol Methyl Ether Acetate 3%

[0067] Toluene 2%

[0068] DBE 1%

[0069] Auxiliary 1%

[0070] Weigh each component of the above content, use the mixture of butyl acetate, propylene glycol methyl ether acetate, DBE and toluene as solvent, divide the solvent into two parts: the first part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com