Method for improving dyeing quality of hand sample and hand sample dyeing machine equipped with stainless steel dyeing cup

A dyeing machine, stainless steel technology, applied in the direction of processing textile material dyeing devices, processing textile material containers, etc., can solve the problems of reducing the dyeing space, low proofing efficiency, uneven dyeing, etc., to improve proofing efficiency and prevent dyes from gathering. , the effect of uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

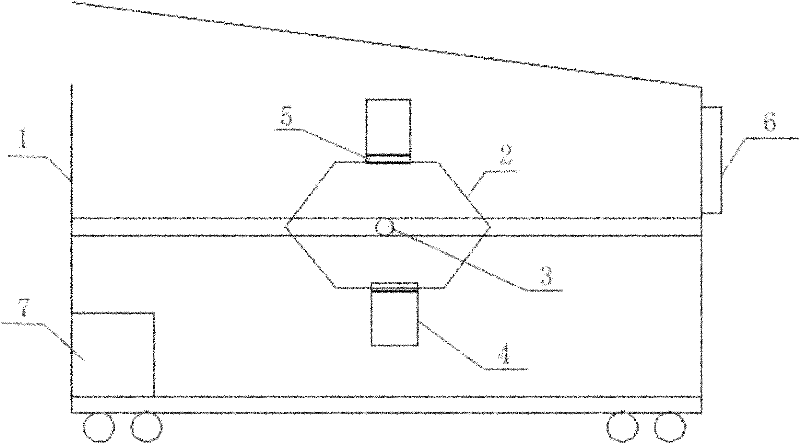

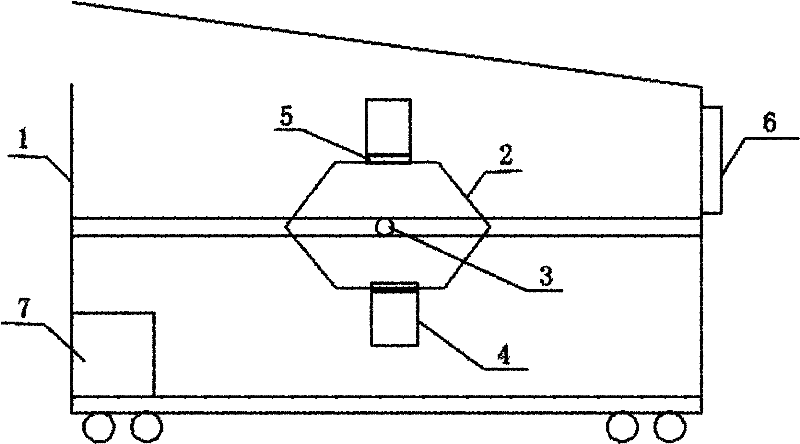

Image

Examples

Embodiment 1

[0025] Fabric: 32STK single yarn jersey

[0026] 1. According to the color requirements, inject the required reactive dyes, sodium sulfate and water into the stainless steel dyeing cup;

[0027] 2. Put five stainless steel balls with a diameter of 2mm into the dyeing cup;

[0028] 3. Put a certain quality of scouring or bleached cloth, cover the cup and confirm that there is no leakage;

[0029] 4. Insert the dyeing cup into the dyeing seat of the small rotary prototype machine in the water bath, and start the dyeing process.

Embodiment 2

[0031] Fabric: 150D / 288FDTY+100D / 36FDTY double-sided fleece

[0032] 1. According to the color requirements, pour the required disperse dye, glacial acetic acid, dispersant and water into the stainless steel dyeing cup;

[0033] 2. Put five stainless steel balls with a diameter of 5mm into the dyeing cup;

[0034] 3. Put in a degreasing sample cloth of a certain quality, cover the cup and confirm that there is no leakage;

[0035] 4. Insert the dyeing cup into the dyeing seat of the small rotary prototype machine in the water bath, and start the dyeing process.

[0036] The invention is simple and easy to operate, does not change the original technological process, has small investment and remarkable effect, avoids uneven dyeing phenomena such as colored flowers and stains in proofing, and improves the proofing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com