Dyeing and finishing process of recycle polyester

A technology of recycled polyester, dyeing and finishing, applied in the field of fabric dyeing and finishing, can solve the problems of uneven dyeing, easy bursting, strength drop and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Pre-treatment: immerse the recycled polyester fabric to be printed and dyed in a compound tea saponin solution at 100°C for 40 minutes, the liquor ratio is 1:5, and the compound tea saponin solution is 30g of compound tea saponin per liter of water, and wait for compounding After the tea saponin is dissolved, it is heated up to 100°C; after the treatment, it is washed with water; wherein, the compound tea saponin is Bugong tea saponin, and its composition is 1% nano-titanium oxide, tea saponin 12%, methyl cellulose 1%, natural soap powder 23%, diatomaceous earth 3%, sepiolite 6%, sodium carbonate 5%, the rest is water;

[0038] (2) Dyeing: Place the regenerated polyester fabric through the pretreatment process in the dye solution, the dyestuff is disperse dye RED S-GLF, the amount of dyestuff is 2% of the fabric weight, and the leveling agent is 2g / L (NICCASUNSOLT 7000Z, Zhejiang Rihua Chemical Co., Ltd.); prepare the dye liquor according to the weight ratio of the ...

Embodiment 2

[0044] (1) Pretreatment: With reference to Example 1, the difference from Example 1 is that the compound tea saponin includes bugong tea saponin and sodium silicate, and the consumption of sodium silicate is 40wt of bugong tea saponin %, the composition of bugong tea saponin is the same as in Example 1.

[0045] (2) dyeing: with embodiment 1.

[0046] (3) cleaning: with embodiment 1.

[0047] (4) heat setting: with embodiment 1.

[0048] (5) Napping: the same as in Example 1.

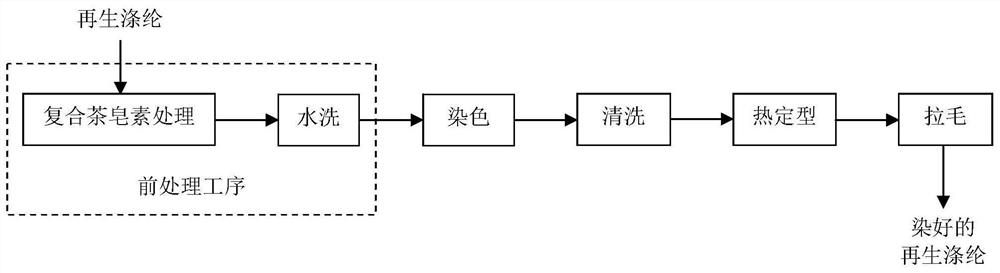

[0049] Its process flow chart is as figure 1 shown.

Embodiment 3

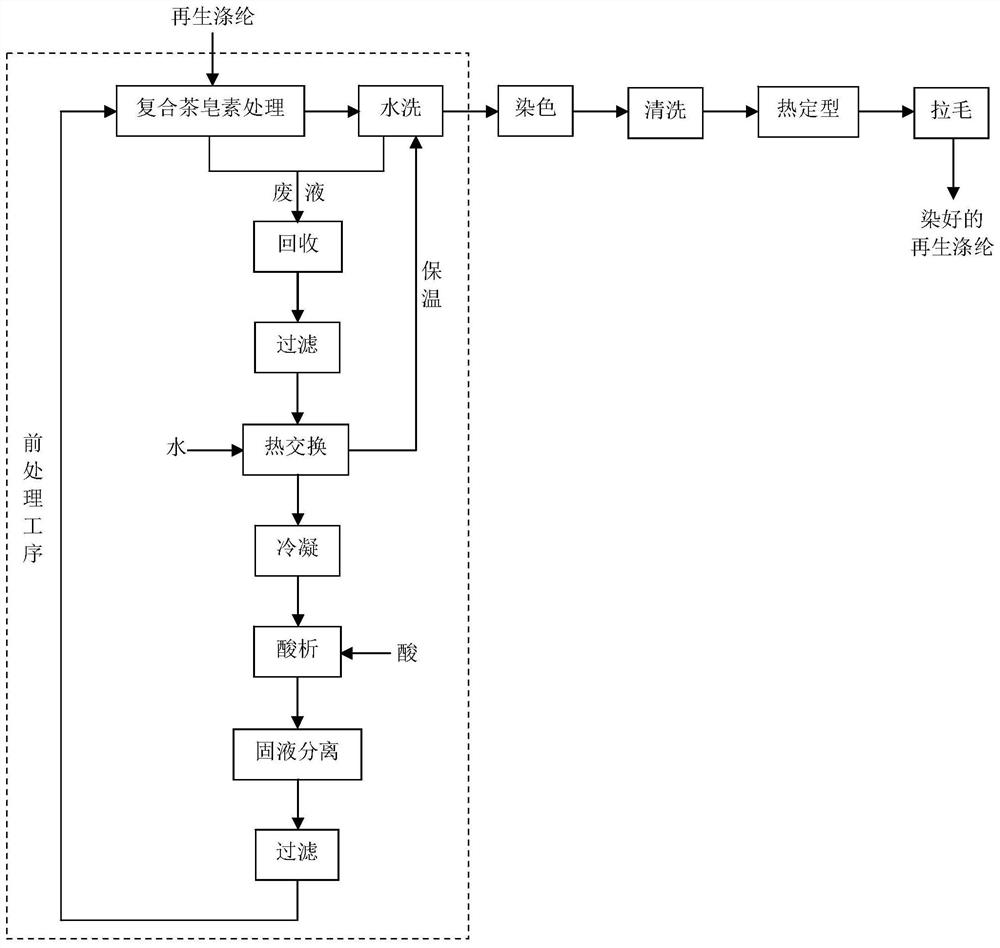

[0051] (1) Pretreatment: With reference to Example 1, the difference from Example 1 is that after the treatment, the waste liquid and washing waste liquid generated when the compound tea saponin is processed on the regenerated polyester fabric are also recycled, and recycled as a compound The solution used when tea saponin is used to treat recycled polyester fabrics, the process of recycling is specifically:

[0052] The waste liquid and washing waste liquid generated when compound tea saponin is used to treat polyester fabrics are recovered and filtered, and then enter the heat exchange system, and perform heat exchange with normal temperature tap water entering the heat exchange system; after heat exchange, the temperature of normal temperature tap water rises to 50 ℃, used as washing water in the pre-treatment process; the waste liquid is reduced to 50 ℃ after heat exchange, and then further condensed to 8 ℃, and then add dilute sulfuric acid with a concentration of 40vol% f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com