A kind of leveling agent for cotton and preparation method thereof

A leveling agent and a uniform technology, applied in the field of textile printing and dyeing, can solve the problems of color flowering and uneven dyeing, and achieve the effects of preventing dye aggregation, prolonging the migration process, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

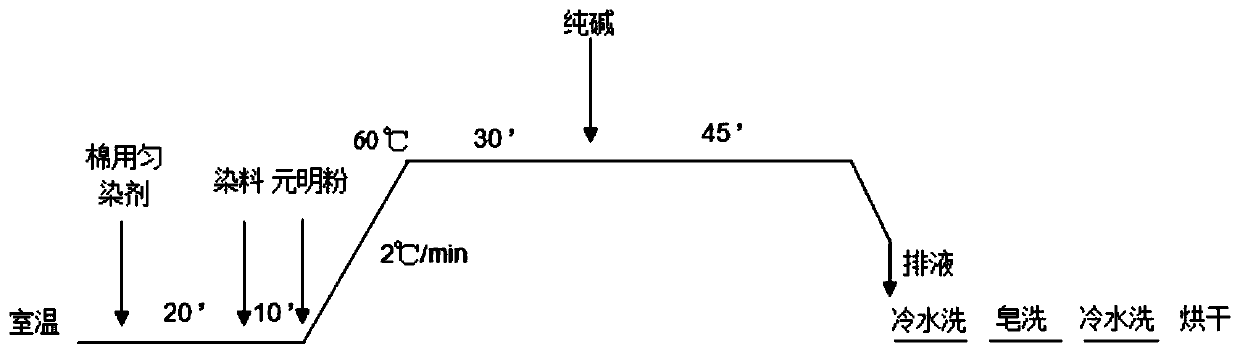

Method used

Image

Examples

Embodiment 1

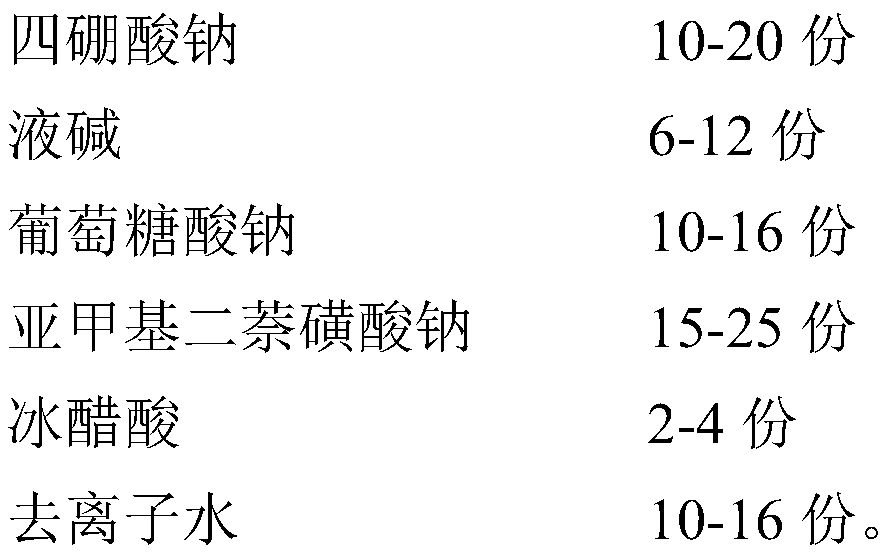

[0032] A kind of leveling agent for cotton, the preparation method of described leveling agent for cotton is:

[0033] (1) Add 16 parts of deionized water into a clean reactor, heat up to 60°C, add 30 parts of glycerin, and stir for 15 minutes at a speed of 800 rpm until completely uniform;

[0034] (2) Add 20 parts of sodium tetraborate decahydrate, and stir for 35 minutes at a speed of 1000 rpm until completely uniform;

[0035] (3) Under stirring state at 800 rpm, slowly add 12 parts of liquid caustic soda (50% concentration by mass), and stir for 20 minutes until completely dissolved;

[0036] (4) Add 16 parts of sodium gluconate, and stir for 40 minutes until completely dissolved at a speed of 800 rpm;

[0037] (5) Add 25 parts of sodium methylene dinaphthalene sulfonate, at a speed of 800 rpm, stir for 40 minutes until completely dissolved;

[0038] (6) Use 4 parts of glacial acetic acid to adjust the pH value to 7, and stir for 20 minutes at a speed of 800 rpm; the gl...

Embodiment 2

[0041] A kind of leveling agent for cotton, the preparation method of described leveling agent for cotton is:

[0042] (1) Add 10 parts of deionized water into a clean reactor, heat up to 50°C, add 16 parts of glycerin, and stir for 10 minutes at a speed of 300 rpm until completely uniform;

[0043] (2) Add 10 parts of sodium tetraborate decahydrate, and stir for 25 minutes at a speed of 500 rpm until completely uniform;

[0044] (3) Under stirring at 200 rpm, slowly add 6 parts of liquid caustic soda (50% by mass), and stir for 10 minutes until completely dissolved;

[0045] (4) Add 10 parts of sodium gluconate, and stir for 30 minutes at a speed of 200 rpm until completely dissolved;

[0046] (5) Add 15 parts of sodium methylene dinaphthalene sulfonate, at a speed of 200 rpm, stir for 30 minutes until completely dissolved;

[0047] (6) Use 2 parts of glacial acetic acid to adjust the pH value to 6, and stir for 20 minutes at a speed of 500 rpm; the glacial acetic acid is d...

Embodiment 3

[0050] A kind of leveling agent for cotton, the preparation method of described leveling agent for cotton is:

[0051] (1) Add 13 parts of deionized water into a clean reactor, heat up to 55°C, add 23 parts of glycerin, and stir for 12 minutes at a speed of 550 rpm until completely uniform;

[0052] (2) Add 15 parts of sodium tetraborate decahydrate, and stir for 30 minutes at a speed of 750 rpm until completely uniform;

[0053] (3) Under stirring at 500 rpm, slowly add 9 parts of liquid caustic soda (50% concentration by mass), and stir for 15 minutes until completely dissolved;

[0054] (4) Add 13 parts of sodium gluconate, at a speed of 500 rpm, stir for 35 minutes until completely dissolved;

[0055] (5) Add 20 parts of sodium methylene dinaphthalene sulfonate, and stir for 35 minutes at a speed of 500 rpm until completely dissolved;

[0056](6) Use 3 parts of glacial acetic acid to adjust the pH value to 6.5, and stir for 20 minutes at a speed of 650 rpm; the glacial a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com