Alkali-free dyeing process for reactive dye

A reactive dye and process technology, applied in the field of fabric dyeing, can solve the problems that the finished product is prone to color flower, the amount of soda ash or trisodium phosphate is large, and the production process of the dyeing process is lengthy, and the effect of reducing the COD value and improving the equipment capacity can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

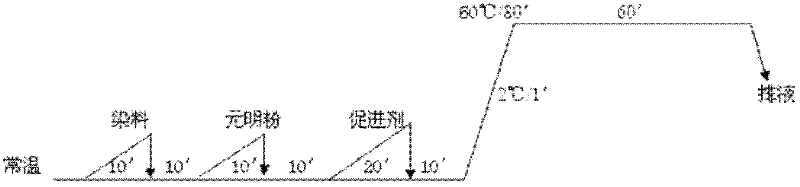

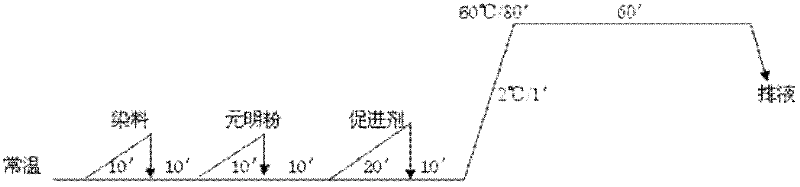

[0007] The present invention will be further described now in conjunction with accompanying drawing.

[0008] see figure 1 , the present invention is carried out successively according to the following process steps: 1. Under normal temperature, first put the dyed fabric or yarn into the dyeing vat, then add the dissolved dye into the dyeing vat for ten minutes; 2. Run for ten minutes; 3. , the Yuanmingfen Na 2 so 4 After the auxiliary vat is dissolved, slowly add to the dye vat for ten minutes; 4, run for ten minutes; 5, add accelerator 169 to the dye vat for twenty minutes; 6, run for ten minutes; 7, increase the temperature by two degrees Celsius per minute Heating the dyeing vat at a high speed, when the temperature in the dyeing vat reaches 60 degrees Celsius, stop heating and keep the temperature at 60 degrees Celsius for 20 minutes; 8, run for 60 minutes; 9, after the dyeing is completed, discharge the dye solution in the dyeing vat into the Subsequent washing proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com