Anti-wave ocean platform

An ocean platform, wave-type technology, applied in breakwaters, sea area engineering, coastline protection, etc., can solve problems such as unsatisfactory wave dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

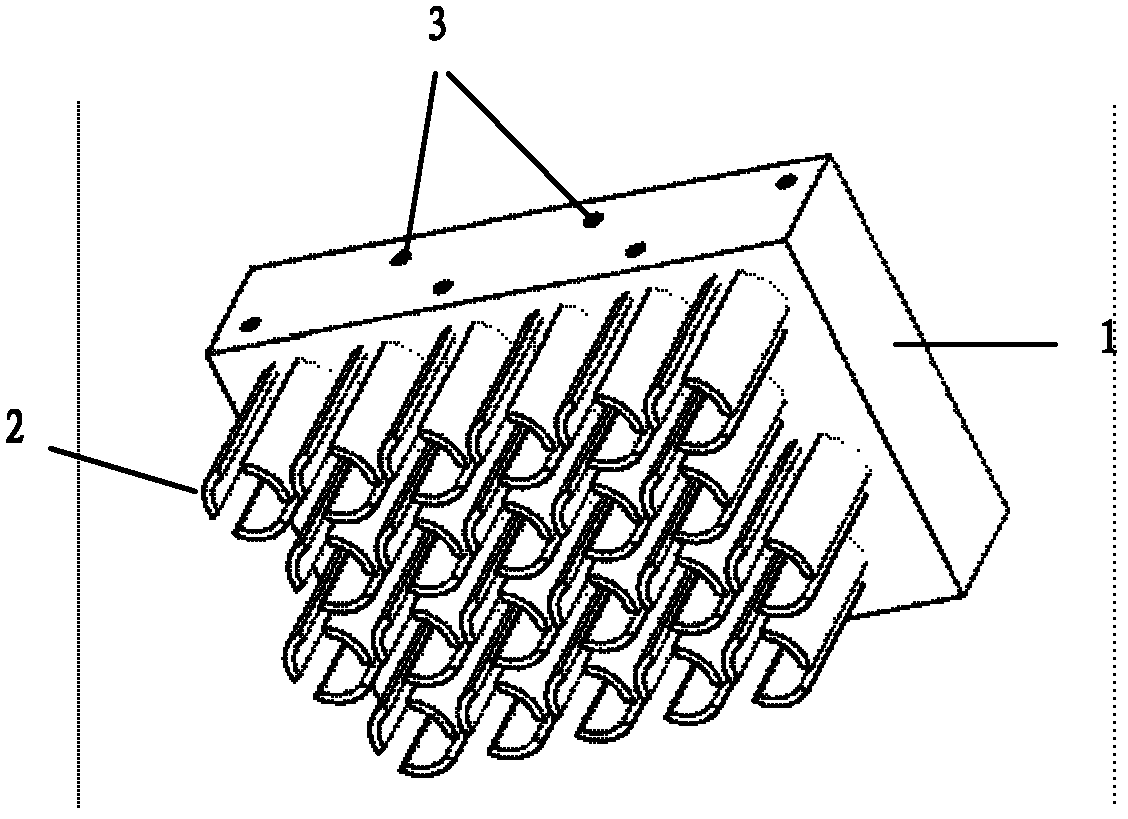

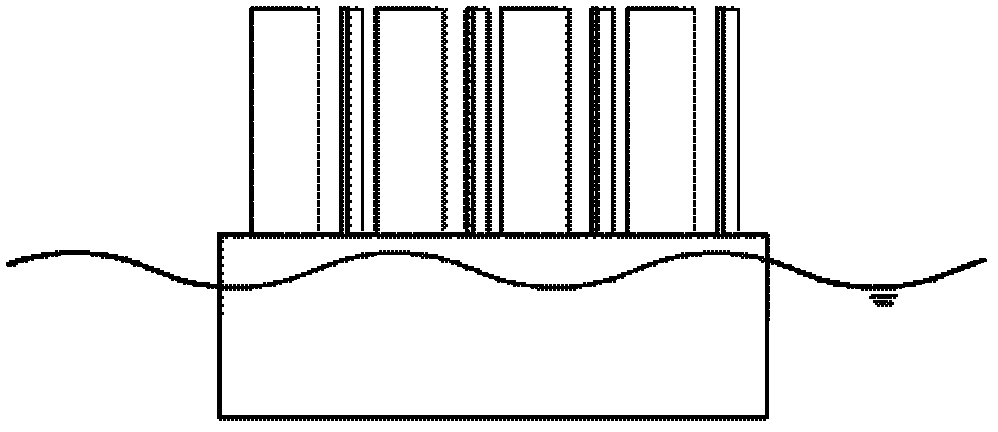

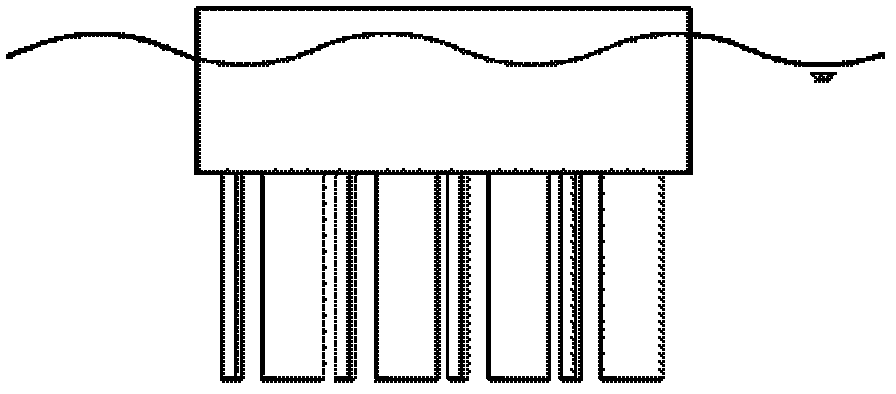

[0020] The invention discloses a wave-proof offshore platform (Fig. 1), which includes a buoyancy tank 1 and a wave-dissipating element 2. A valve 3 is arranged on the surface of the buoyancy tank. When the valve is opened, the swing of the wave-dissipating element can be changed by filling water or inflating it. Put the posture, the lower end of the buoyancy tank is connected with the wave-eliminating element. The buoyant tank is divided into several spaces by dividing plates, and each space has a water filling valve, a drainage valve and an inflation and exhaust valve. In actual use, the number of partitions and the form of separation can be flexibly set according to actual needs, and the valve position must also be adjusted accordingly. As shown in Figure 1, the columnar wave absorbing element in the example diagram adopts a cylindrical structure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com