Hydraulic Pneumatic Compound Piling Hammer

A hydraulic pneumatic, piling hammer technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems that cannot meet the requirements of modern foundation construction, and achieve small radial installation size, avoid pipeline connection, and no oil fume pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments described in the accompanying drawings.

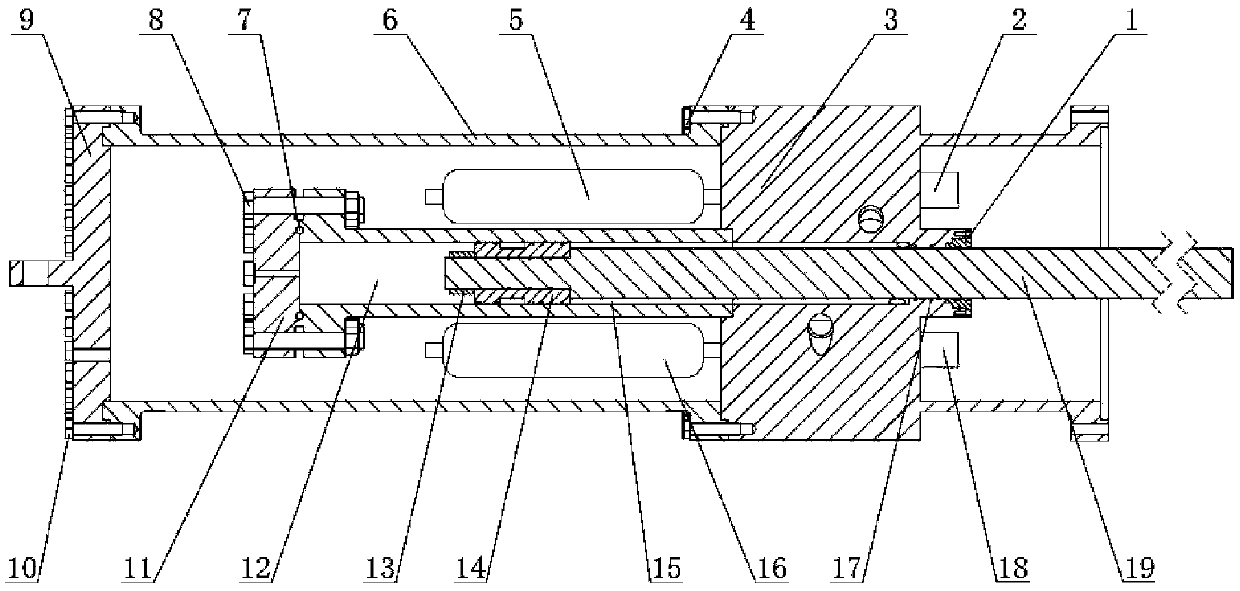

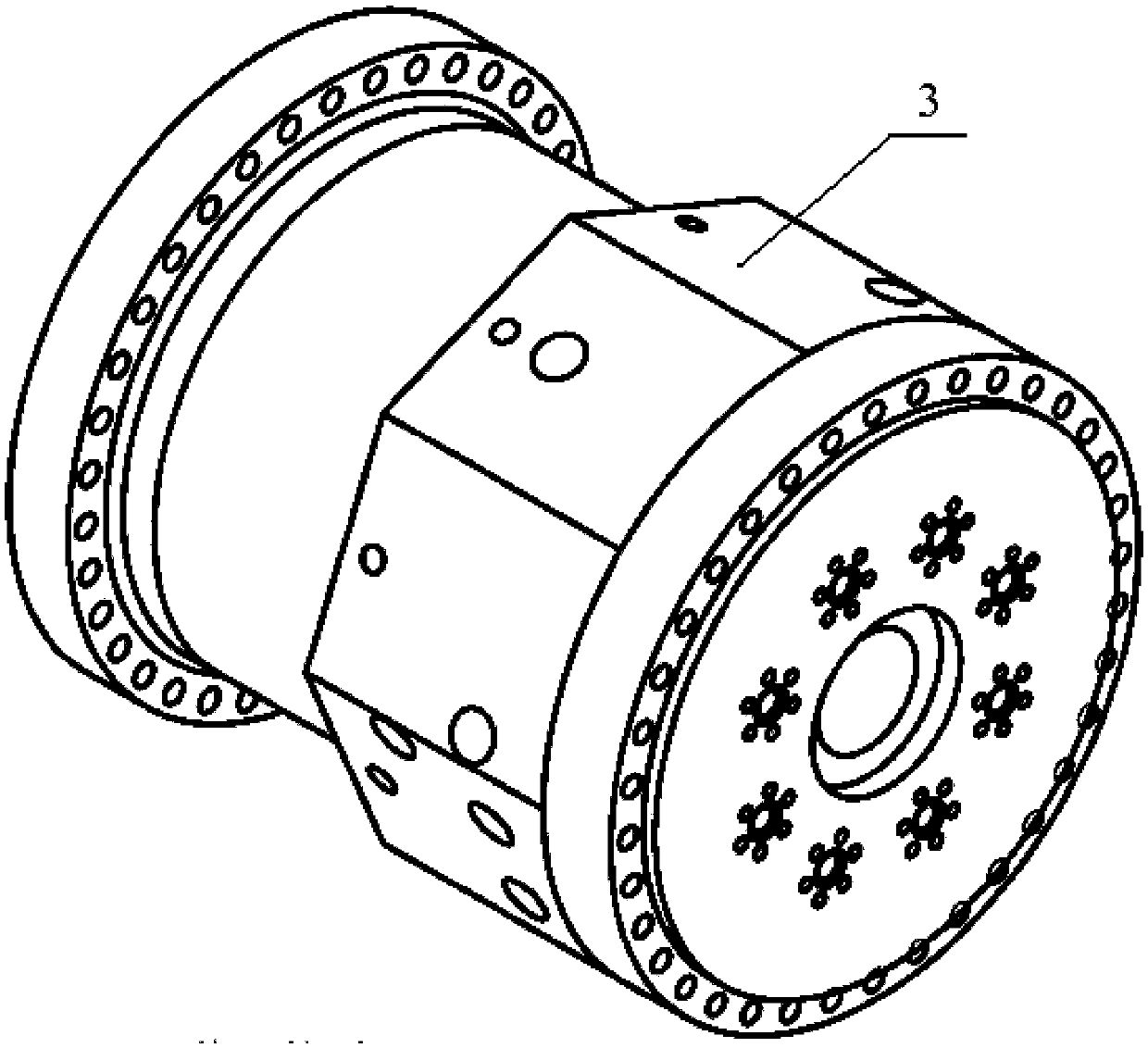

[0025] figure 1It is a structural schematic diagram of the main part of an embodiment of the present invention. As shown in the figure, the hydraulic-pneumatic composite piling hammer of the present invention structurally includes a piston rod end cover assembly 1, an oil supply valve assembly 2, an integrated combined valve block 3, hexagon socket bolt A4, a high-pressure accumulator assembly 5, and a cylinder Body 6, seal 7, hexagon socket bolt B8, ring top cover 9, socket bolt C10, cylinder end cover 11, cylinder 12, lock nut 13, piston 14, hydraulic cylinder (integrated hydraulic pneumatic composite control cylinder) 15 , Low pressure accumulator assembly 16, piston rod seal assembly 17, oil return valve assembly 18, piston rod 19. Wherein, the hydraulic cylinder 15, the piston rod 19, the piston 14, and the cylinder 12 structurally f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com