Enclosing purlin comprising square steel pipe and light concrete for supporting foundation pit

A lightweight concrete and foundation pit support technology, applied in excavation, foundation structure engineering, construction, etc., can solve problems such as inconvenient rust prevention and anti-corrosion treatment, insufficient local bearing capacity, and unfavorable long-term storage, etc., to achieve Easy to lift and carry, light in weight, good bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

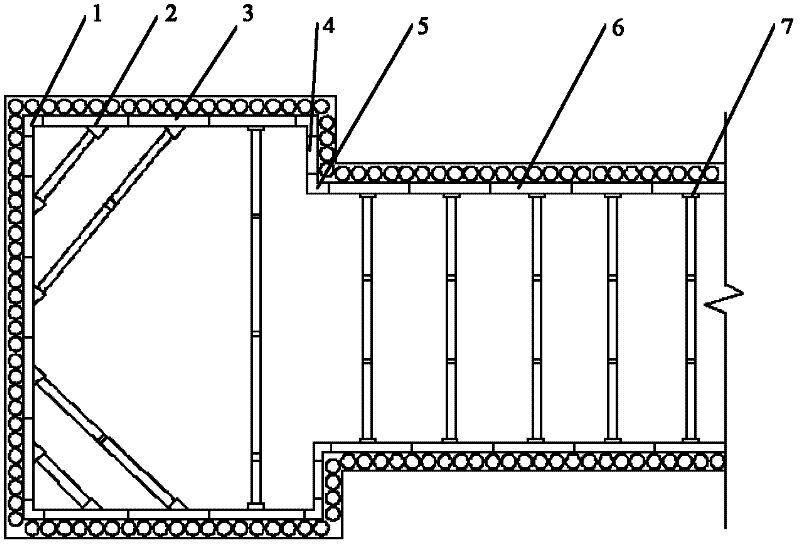

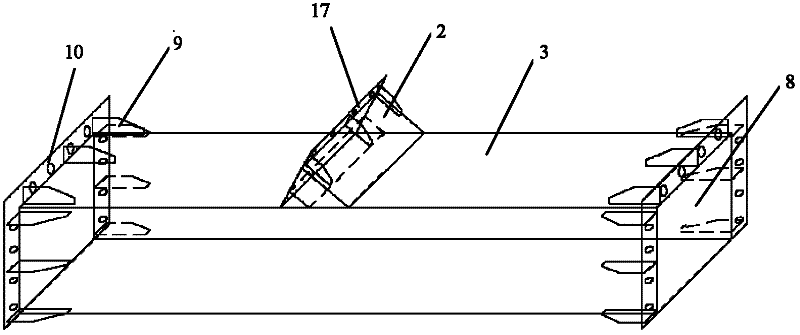

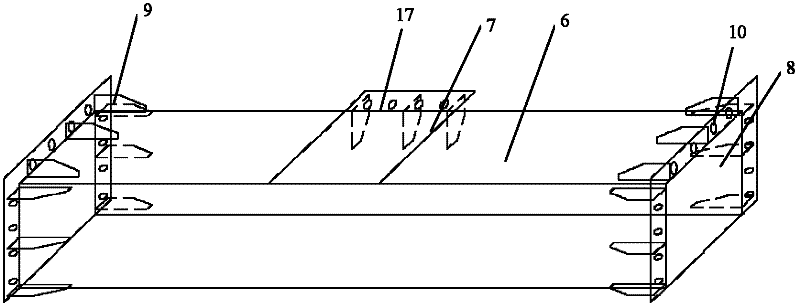

[0026] Below, the technical scheme of the present invention will be further specifically described through an embodiment of a subway station (the end is provided with a shield tunnel widening section) in conjunction with the accompanying drawings.

[0027] The steel pipe lightweight concrete purlin with a side length of 600mm and a wall thickness of 10mm was selected for comparison with the existing steel purlin of 700×300mm. Purlin Construction Regulations”, it is known that the rigidity of steel pipe lightweight concrete purlins is 4.7×10 7 N·m 3 , the steel purlin is 4.5×10 7 N·m 3 , it is relatively known that the stiffness of the designed square steel pipe lightweight concrete purlin is not less than the stiffness of the existing steel purlin, which meets the flexural and compressive strength of the foundation pit purlin.

[0028] Figure 1-8 As shown, the patent of the present invention provides a square steel pipe lightweight concrete purlin for foundation pit suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com