Automatic cleansing fluid release water tank

An automatic cleaning and cleaning liquid technology, applied in water supply devices, sanitary equipment for toilets, buildings, etc., can solve problems such as easy failure, long time for dissolving, inconvenience, etc., to avoid circuit control, reliable work, and output. Liquid volume stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

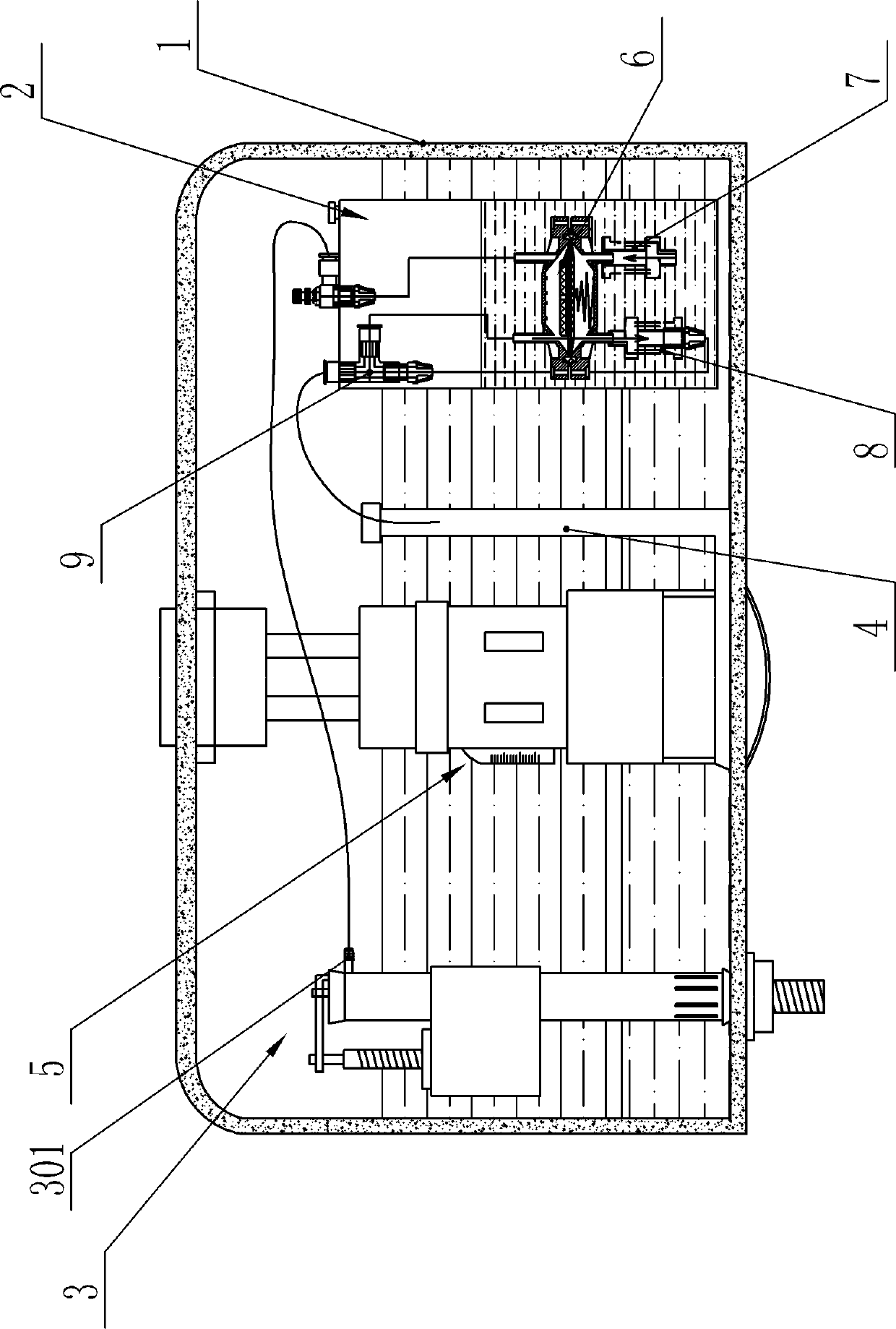

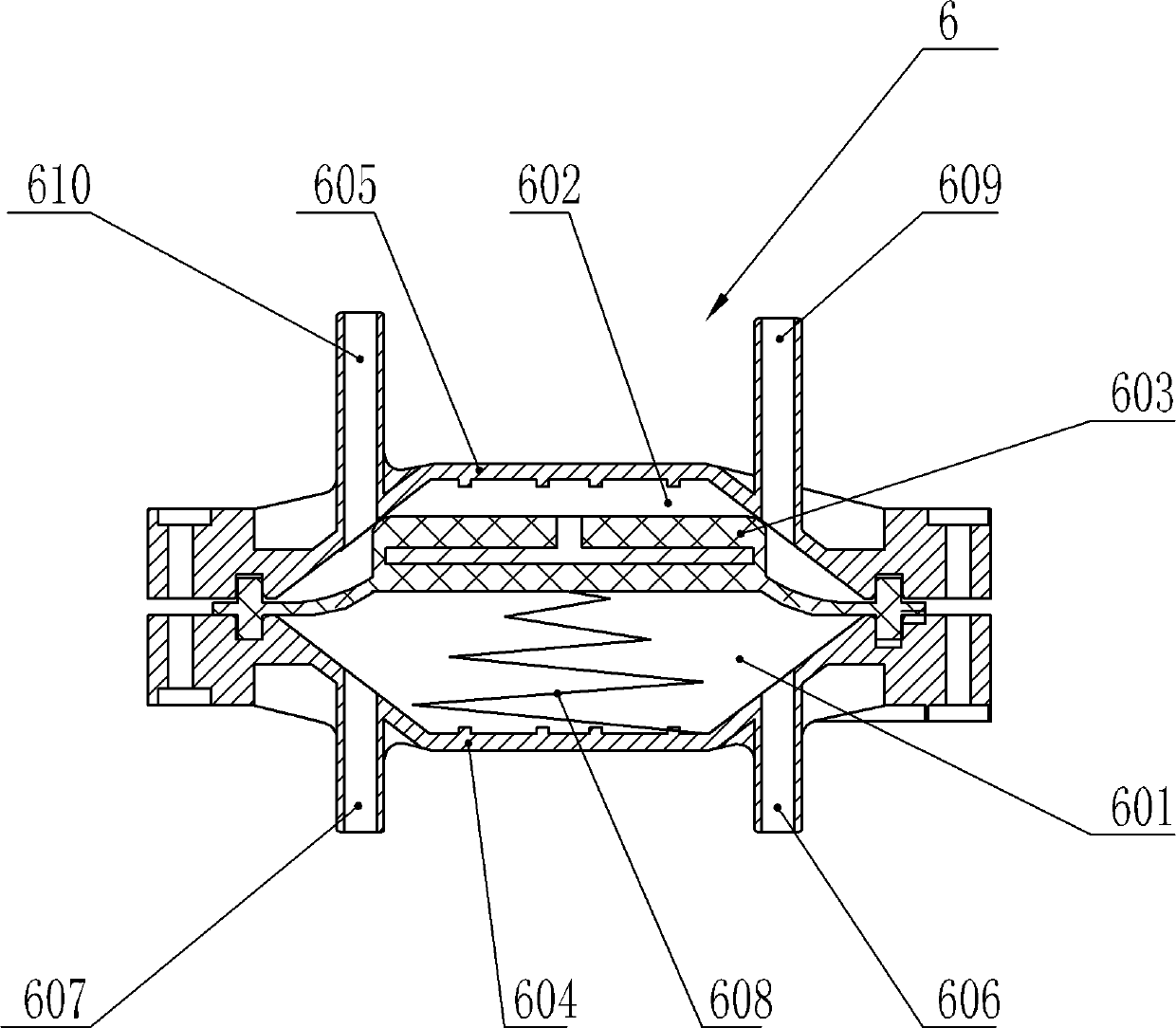

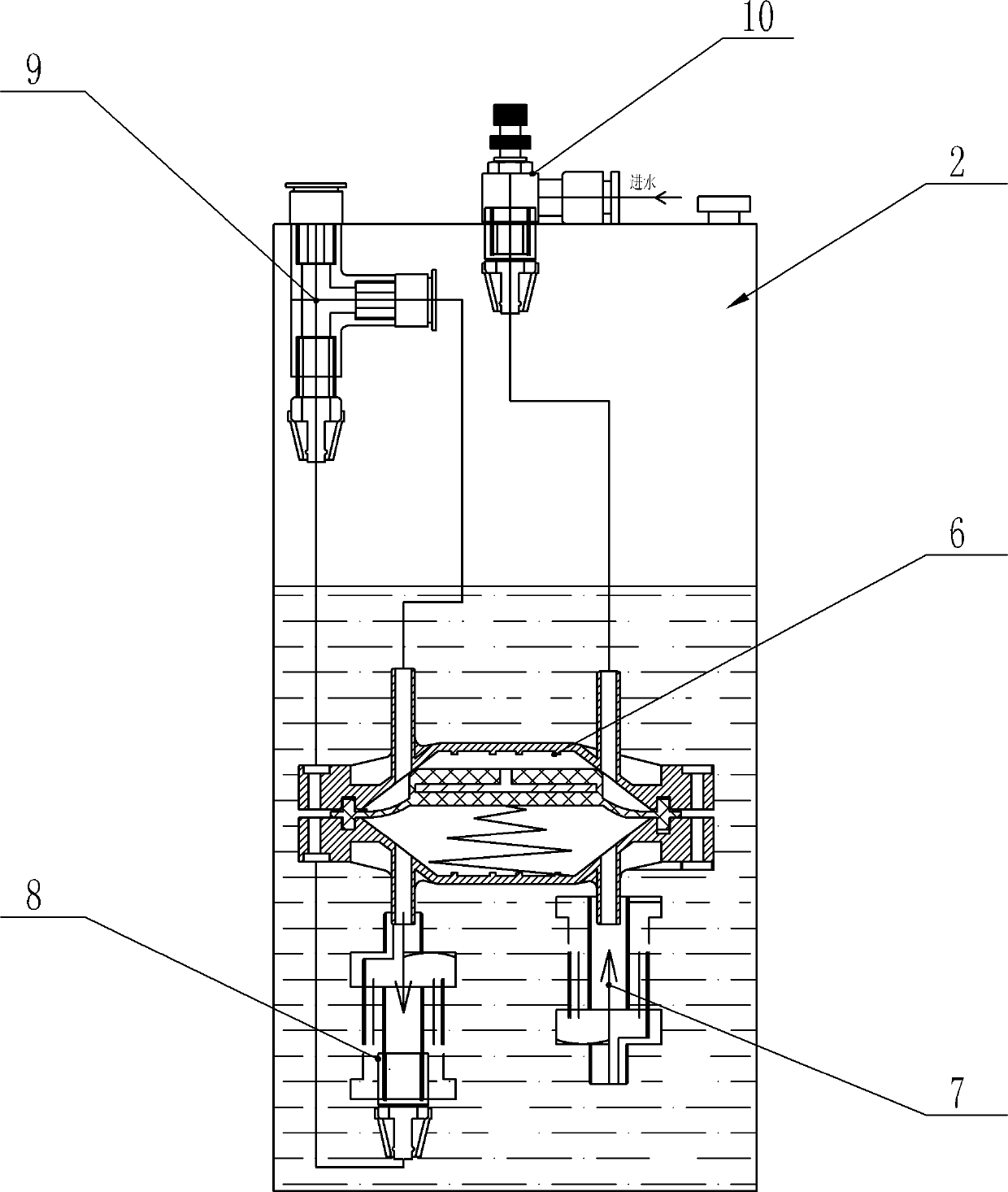

[0014] like figure 1 As shown, the automatic cleaning liquid release water tank includes a cleaning liquid box 2 containing cleaning liquid and a flushing water tank. The flushing water tank includes a box body 1, which is provided with a water part 3, an overflow pipe 4 and a flushing water tank. A valve assembly 5, a liquid aspirator 6, a liquid suction one-way valve 7, a liquid outlet one-way valve 8 and a water-liquid mixing joint 9 are arranged in the cleaning liquid box 2, and the liquid aspirator 6 is provided with a sealed liquid suction chamber 601 and the water pressure chamber 602, the liquid suction chamber 601 and the water pressure chamber 602 are isolated by an elastic diaphragm 603, and the liquid suction device 6 is provided with a reset mechanism for the elastic diaphragm 603, in this specific embodiment ,like figure 2 As shown, the liquid aspirator 6 includes a liquid suction chamber cover 604 and a water pressure chamber cover 605 with an arched concave c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com