Construction method of bearing frame of corridor structure

A construction method and technology of a load-bearing frame, which are applied in building construction, building material processing, construction, etc., to achieve the effects of short construction period, simple load-bearing system and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

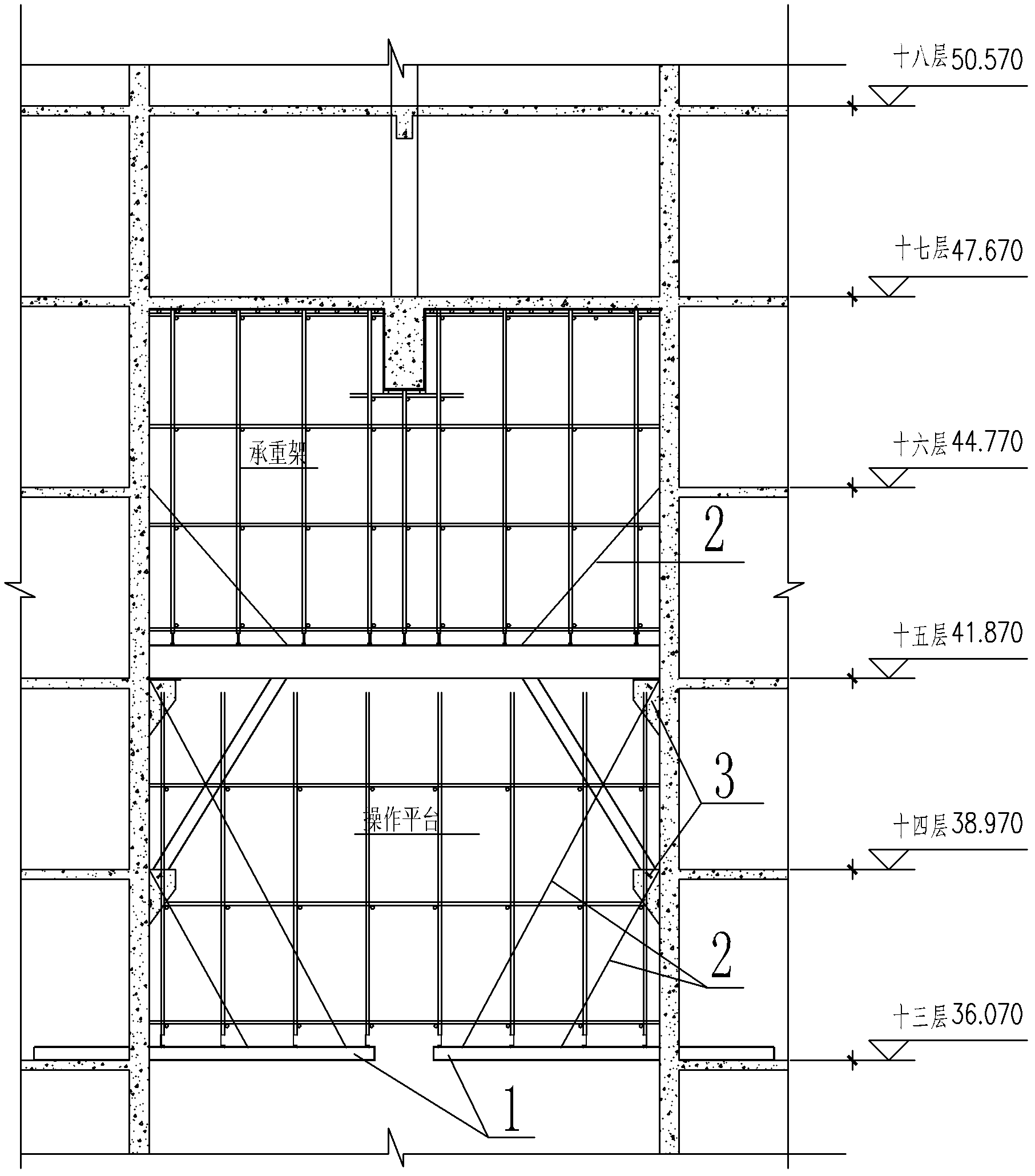

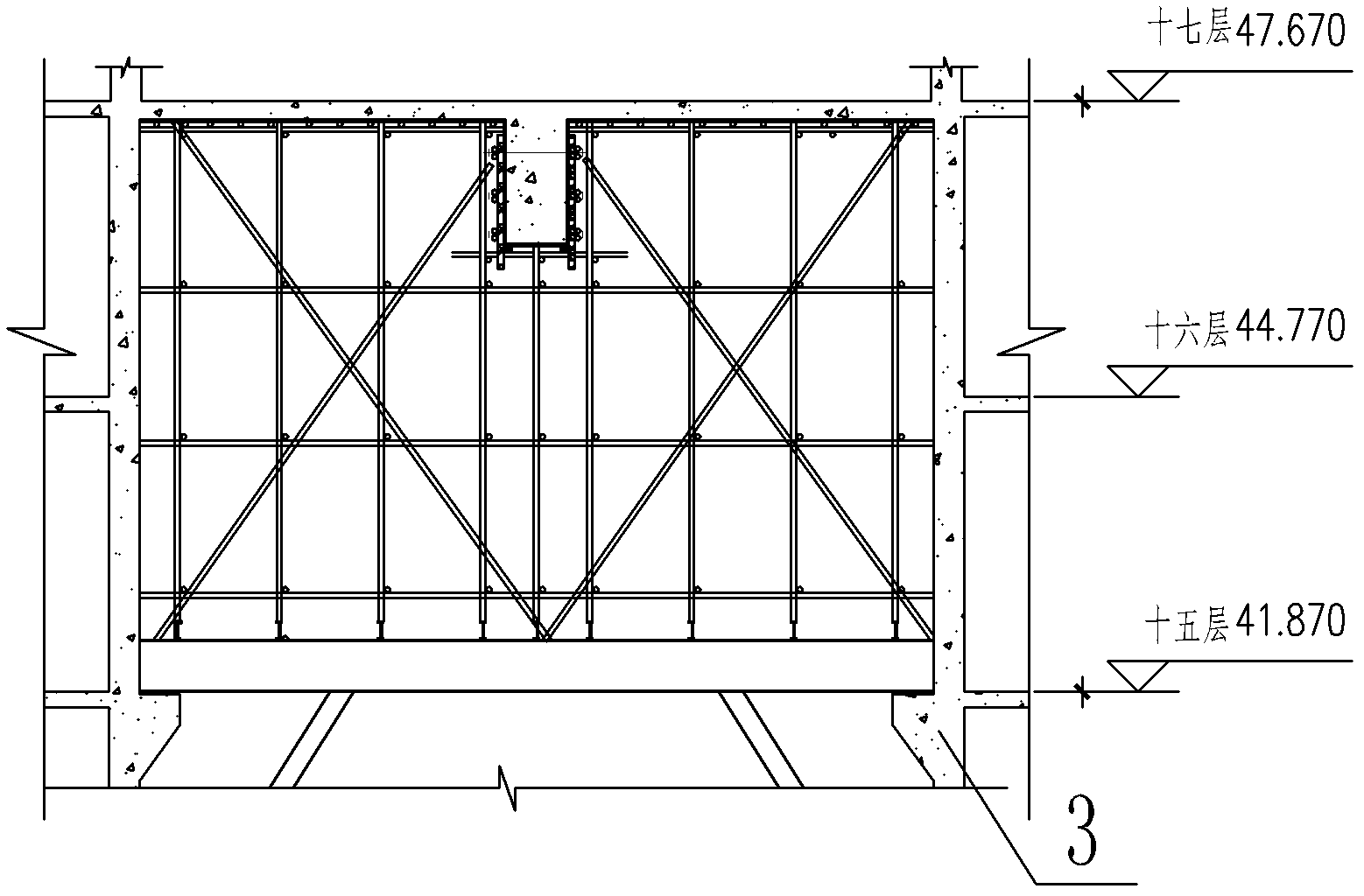

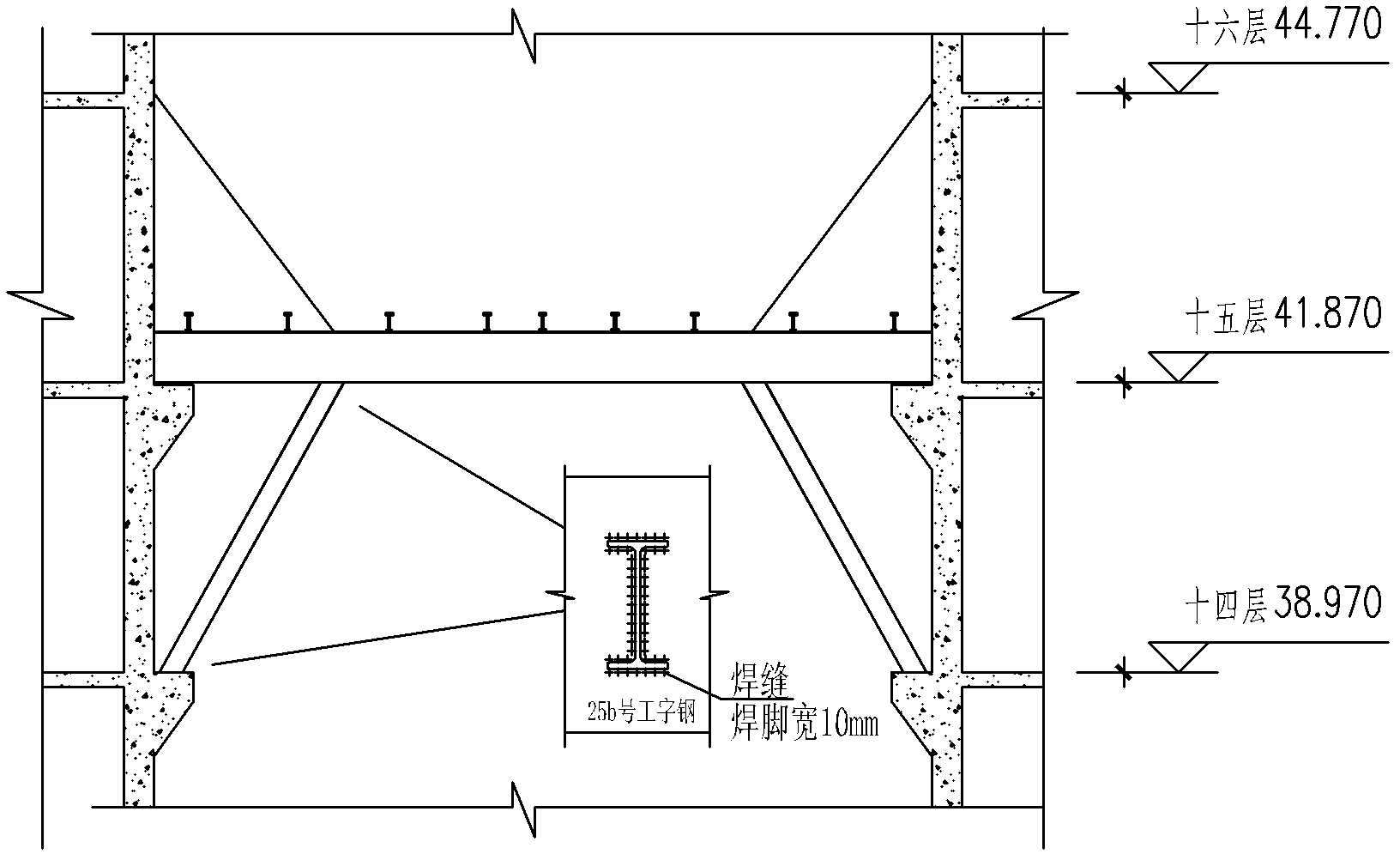

[0031] Such as Figure 1~Figure 3 As shown, the construction method of the corridor structure bearing frame of the present invention specifically comprises the following steps:

[0032] 1 Construction of bearing frame for high-altitude and long-span corridor structure

[0033] 1.1 For the installation and construction safety of the section steel load-bearing platform, an operating platform and a protective frame are set up at its lower part. After the floor concrete is completed, install the cantilevered operating platform 16# section steel 1. The operation platform is erected from the floor structure of the corridor structure, with a total of two floors. Considering the convenience of dismantling, the method of 16# steel cantilevered scaffolding is adopted. The enclosure operating frame is erected to the height of the previous floor.

[0034] 1.2 After the floor concrete is completed, pull the first steel wire rope 2, and use 2 steel wire ropes of 6×37Φ24.5 for each operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com