Combined-type hydraulic chuck for tunnel drilling rig

A technology for hydraulic chucks and tunnel drilling rigs, which is applied to drill pipes, drill pipes, and drilling equipment. It can solve the problems of small holding force, low degree of automation, and cumbersome use and operation, and achieve light weight, small volume, and easy transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

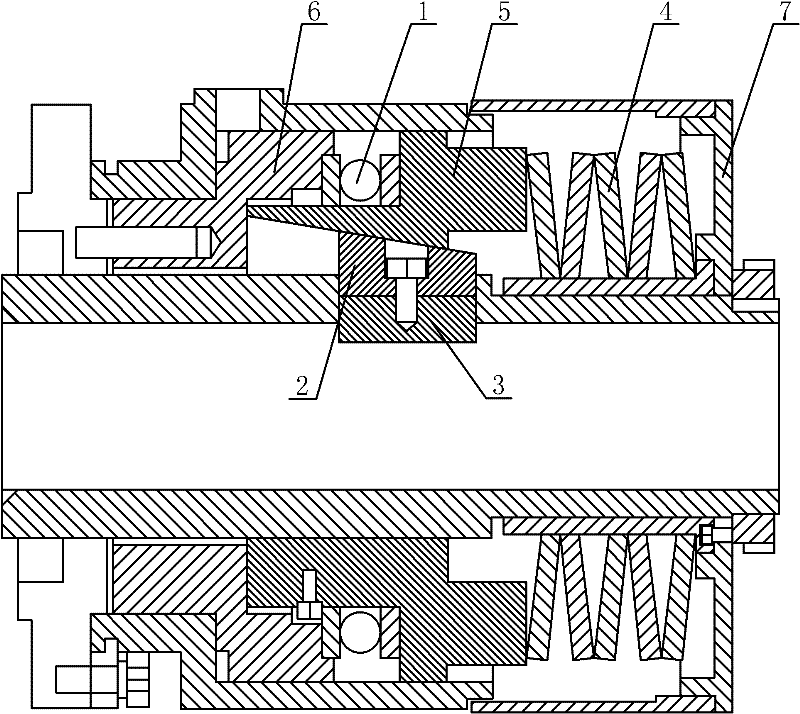

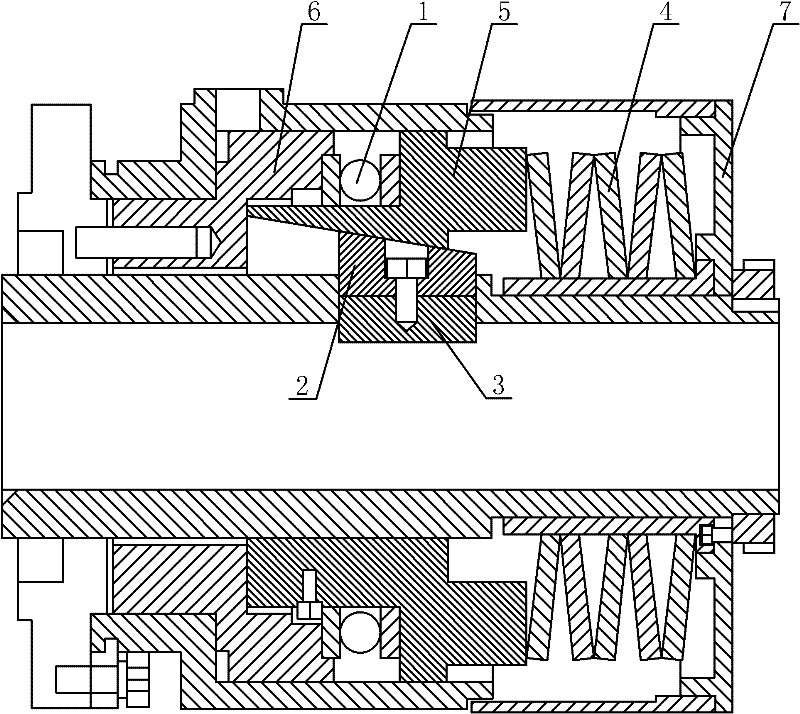

[0019] Such as figure 1 The shown combined hydraulic chuck for a tunnel drilling rig includes slips 3 on which an inner slope mechanism 2 is installed, and an outer slope mechanism 5 is slidingly installed on the outer side of the inner slope mechanism 2. A bearing 1 is arranged between one end of the ramp mechanism 5 and the stop disc one 6 , and a spring 4 is arranged between the other end of the outer ramp mechanism 5 and the stop disc two 7 .

[0020] Such as figure 1 As shown, the inclination angle of the inner bevel mechanism 2 is less than 10°, the inclination angles of the inner bevel mechanism 2 and the outer bevel mechanism 5 are equal, the bearing 1 is a thrust bearing, and the spring 4 is a butterfly spring. The inner slope mechanism 2 is installed on the slips 3 through screws.

[0021] The working process of the combined hydraulic chuck for the tunnel drilling rig of the present invention is as follows: first, the drill pipe of the tunnel drilling rig is insert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com