Pulley type oil pumping machine

A technology for pumping units and pulleys, applied in mechanical equipment, portable lifting devices, belts/chains/gears, etc., can solve the problems of poor motion performance, short stroke, and high energy consumption, achieve convenient maintenance and management, reduce production costs, The effect of reducing the pulling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

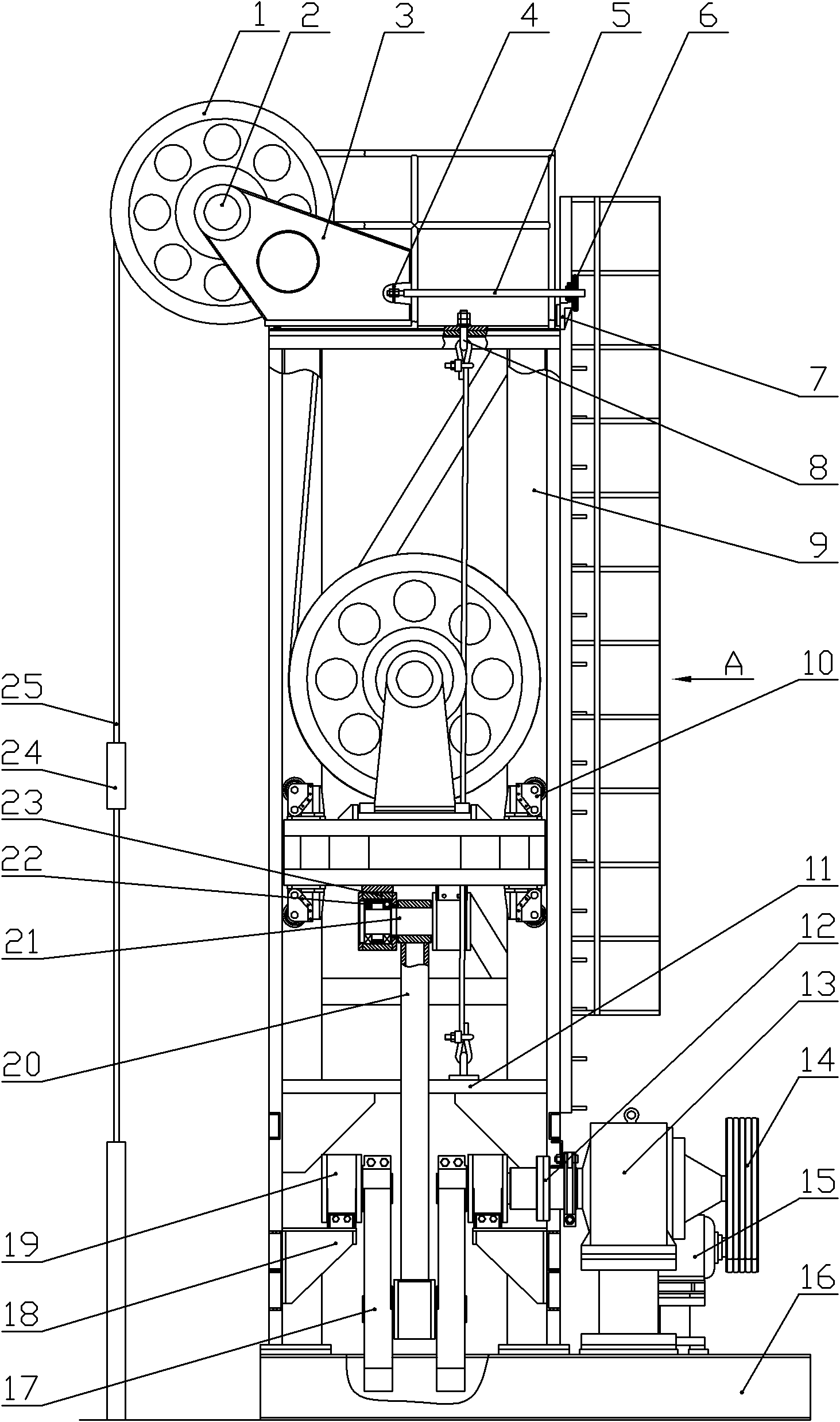

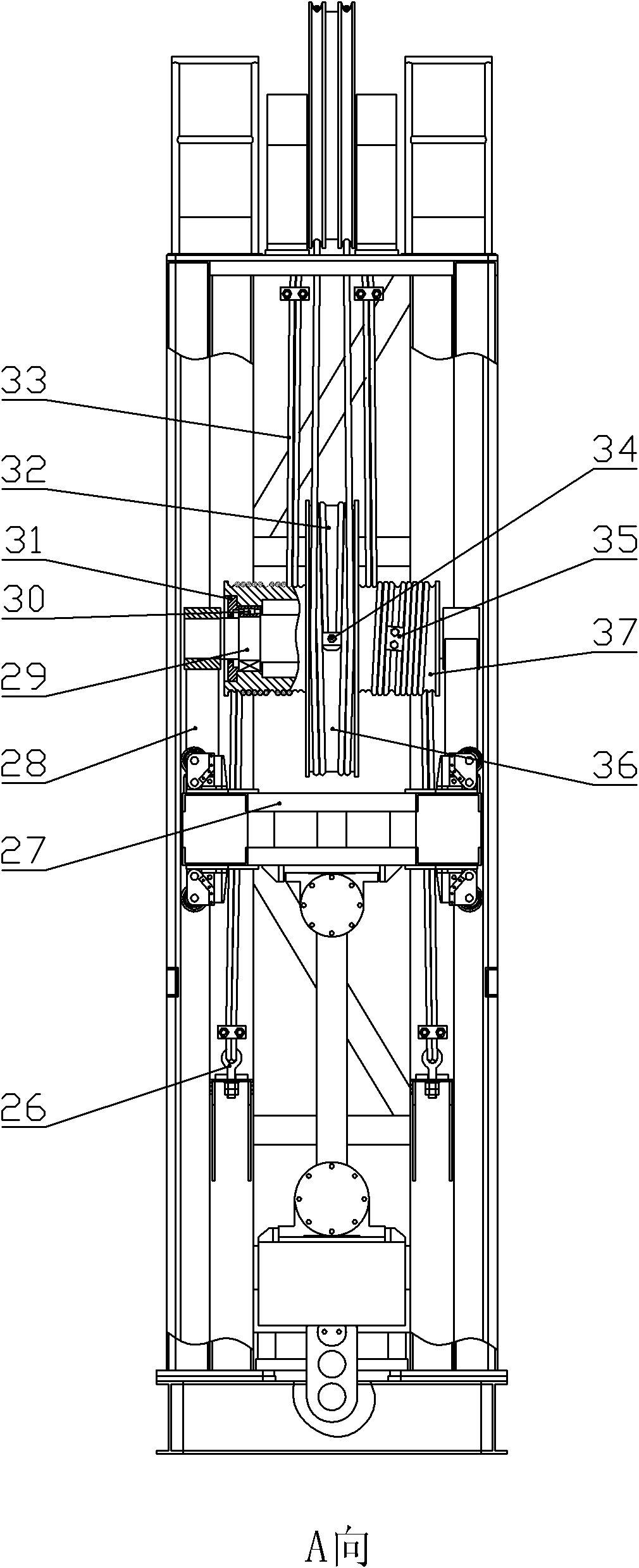

[0019] Reference attached Figure 1~2 :

[0020] The pulley pumping unit includes a base 16 and a frame 9 with a truss structure mounted on the base 16. The sky wheel 1 is connected to the sky wheel support 3 through the sky wheel shaft 2 and the shaft extensions at both ends, and is mounted on the sky wheel support 3 Top of rack 9. The rear end of the top wheel bracket 3 is equipped with a top wheel position adjustment device. The top wheel position adjustment device includes a bracket connecting plate 4 fixed on the top wheel bracket 3, a screw 5 connected with the bracket connecting plate 4, and a nut handwheel for adjusting the screw 5 6. The front shaft end of the screw rod 5 is vertically installed in the middle of the bracket connecting plate 4 in a dynamic fit. The tail part of the screw rod 5 is fitted with a nut handwheel 6 and is fixed on the back side of the top of the frame 9 through a nut seat 7.

[0021] The power unit and the transmission device connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com