Positive pulse device for slurry under shaft

A positive pulse and mud technology, which is used in wellbore/well components, measurement, earth-moving drilling, etc., can solve the problems of well wall damage, slow data transmission speed of mud positive pulse transmission signal, strong erosion effect of parts, etc. Achieve the effect of changing the backhaul response speed, ensuring the data transmission speed, and increasing the pulse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

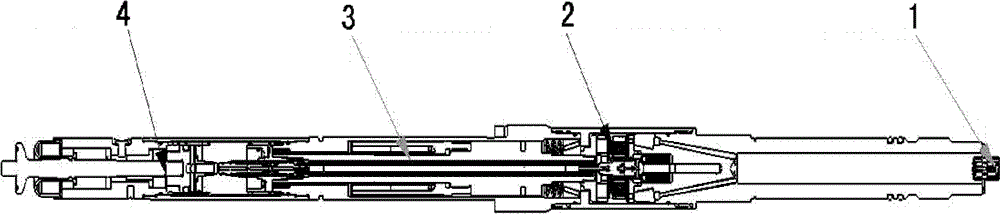

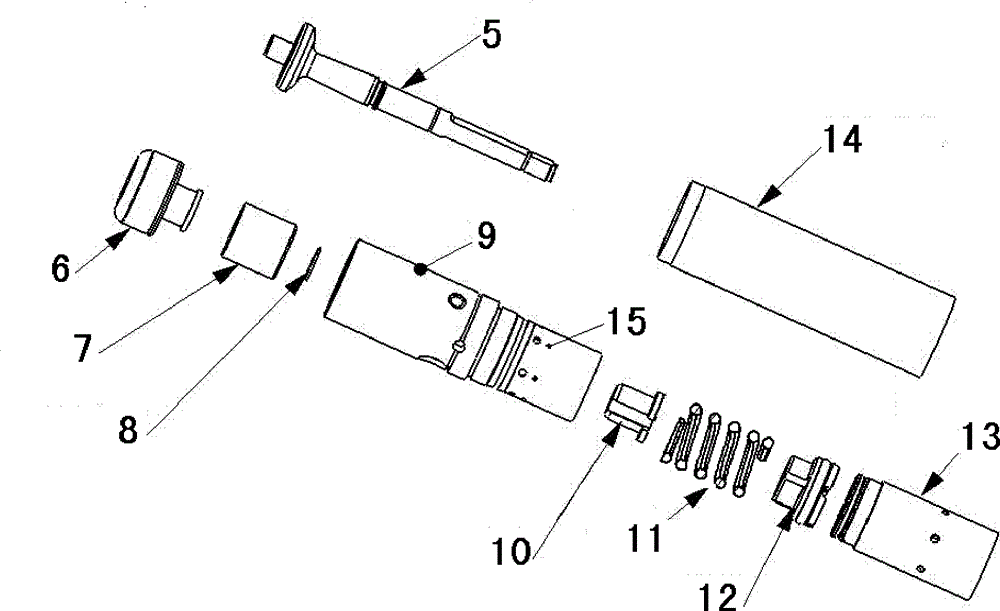

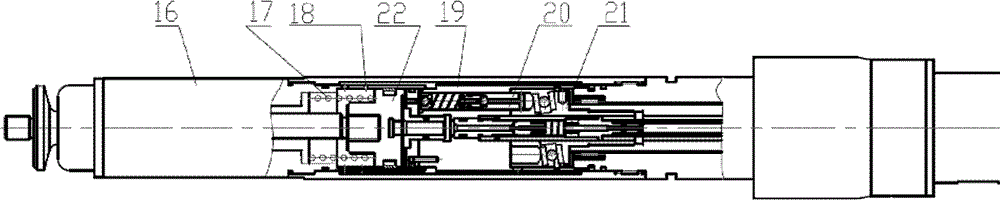

[0019] like figure 1 Shown is a schematic structural view of the downhole mud positive pulse device of the present invention. The downhole mud positive pulse device includes four parts: an output terminal 1, a valve body and a generator assembly 2, an intermediate bearing sleeve 3 and a top assembly 4. Sections are connected sequentially. The setting of the output terminal ensures the communication connection between the downhole mud positive pulse device and other instruments, so that the power generated by the generator can be transmitted, and at the same time receive the control signals of other instruments; the control valve mainly controls the opening and closing of the hydraulic circuit of the pulsator. control the reciprocating motion of the lifting rod at the top to realize pulses; the generator mainly provides electric energy for various instruments in the well; the intermediate bearing sleeve assembly is mainly composed of a magnetic shaft, a generator disk and a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com