Pulse attenuation plunger pump based on resistor-capacitor (RC) filter theory

A pulsation attenuation, plunger pump technology, applied in the components of pumping devices for elastic fluids, machines/engines, pump elements, etc., can solve the problems of size and mass limitations, volume limitations, complex structures, etc. Simple, small size and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

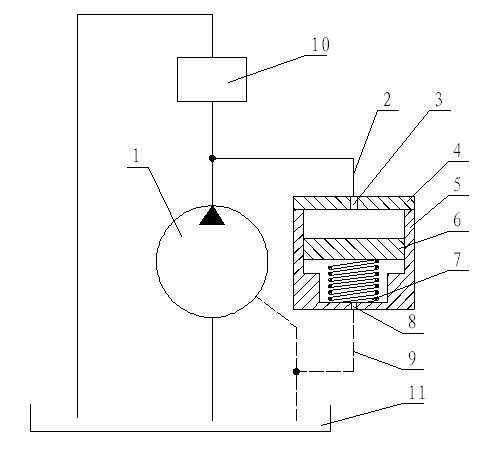

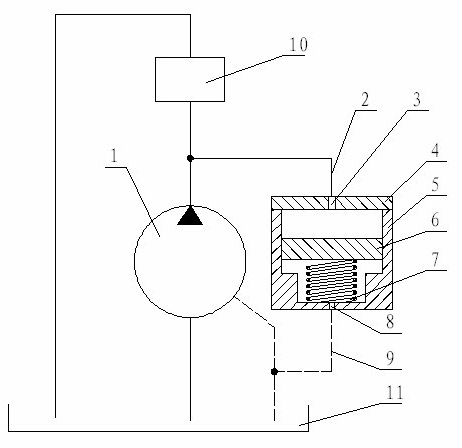

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

[0017] As shown in the drawings, the present invention includes a plunger pump 1, a load 10 and an oil tank 11; it is characterized in that: it also includes a front end cover 4, a housing 5, a piston 6 and a spring 7; the oil outlet of the plunger pump 1 is divided into Two lines, one line connects to the oil tank 11 after the load 10, and the other line 11 communicates with the high-pressure oil damping hole 3 on the front end cover 4 of the housing 5 through the pressure oil line 2, and the piston 6 and the spring are arranged in the housing 5 from top to bottom 7. The low-pressure oil damping hole 8 at the lower end of the casing 5 is connected to the oil leakage port of the plunger pump 1 through the low-pressure oil circuit 9 and then connected to the oil tank 11 . The pulsation attenuation device included in the present invention can be placed inside the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com