Inner bush of pump head

A technology of inner bushing and pump head, which is applied in the field of vertical centrifugal pumps, can solve the problems affecting the water flow and lift in the pump body, and achieve the effect of small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

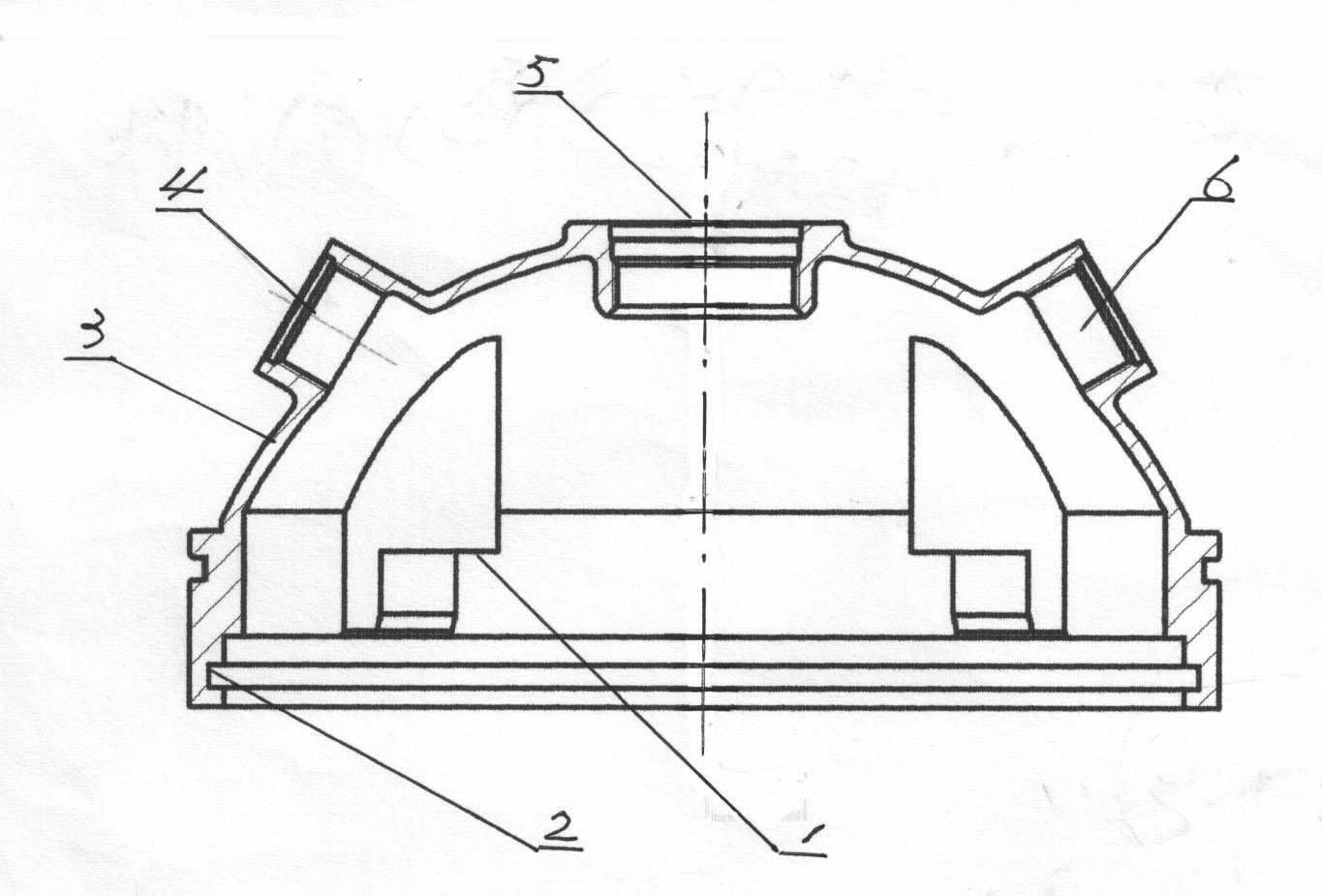

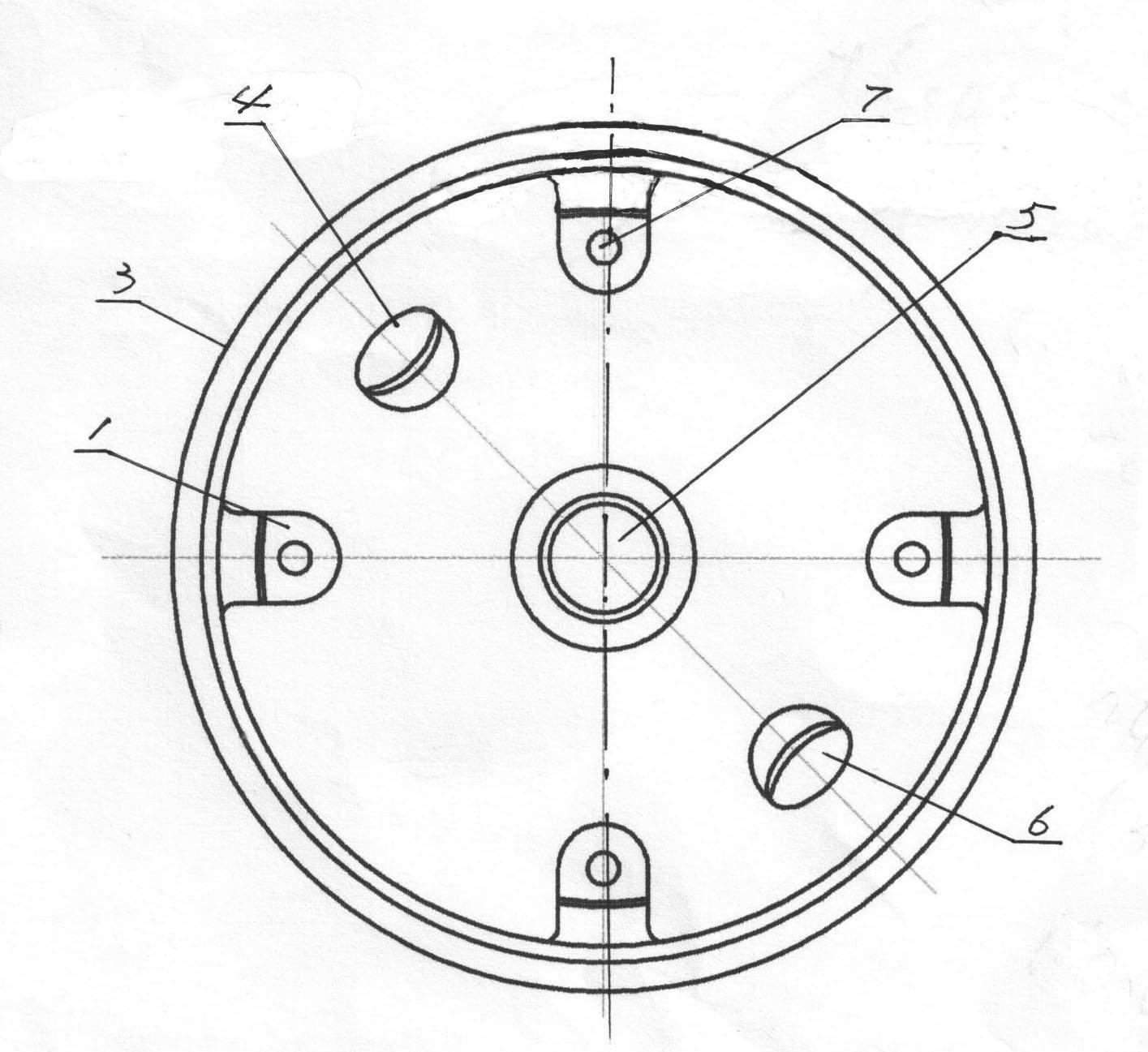

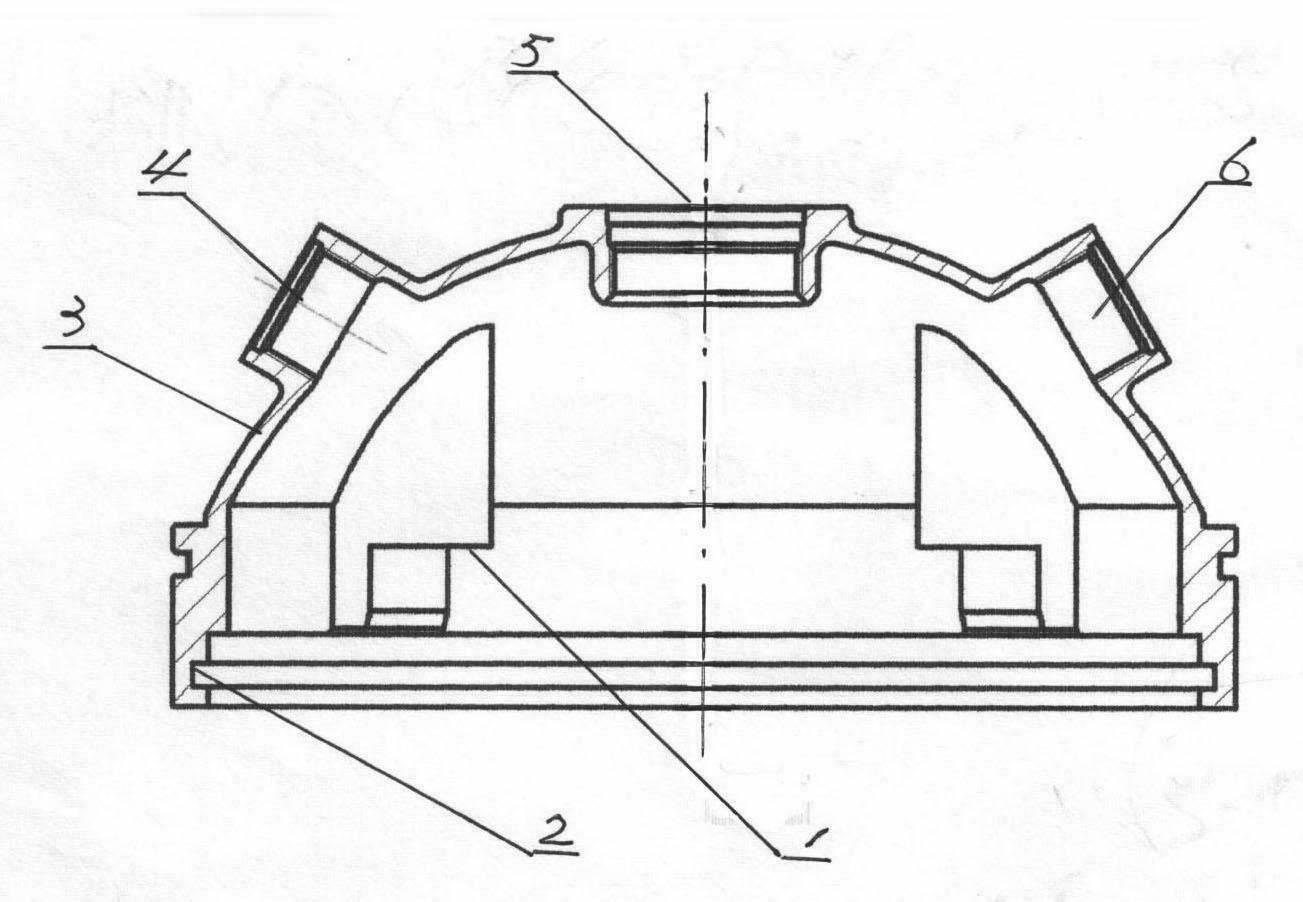

[0014] Such as figure 1 with figure 2 As shown, the pump head inner bushing of the present invention includes a body 3, the body 3 is in the shape of a cover, its top has a hole 5 corresponding to the outer diameter of the pump shaft, and the opening at its lower end is adapted to the upper end of the pump. The inner surface of the body is spherical.

[0015] Wherein, the inside of the body 5 is evenly distributed with four bosses 1 along the circumferential direction, the lower surface of the bosses 1 is parallel to the lower end surface of the body 3, and the lower surface of the bosses 1 is processed with a counterbore 7 for installing a rubber plug , so that in the installed state, it can be fixed with the upper end of the pump body to avoid the rotation of the pump body.

[0016] In addition, a circumferential groove 2 for installing an O-shaped rubber ring is processed on the inner surface of the opening end of the main body 3, so as to cooperate with the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com