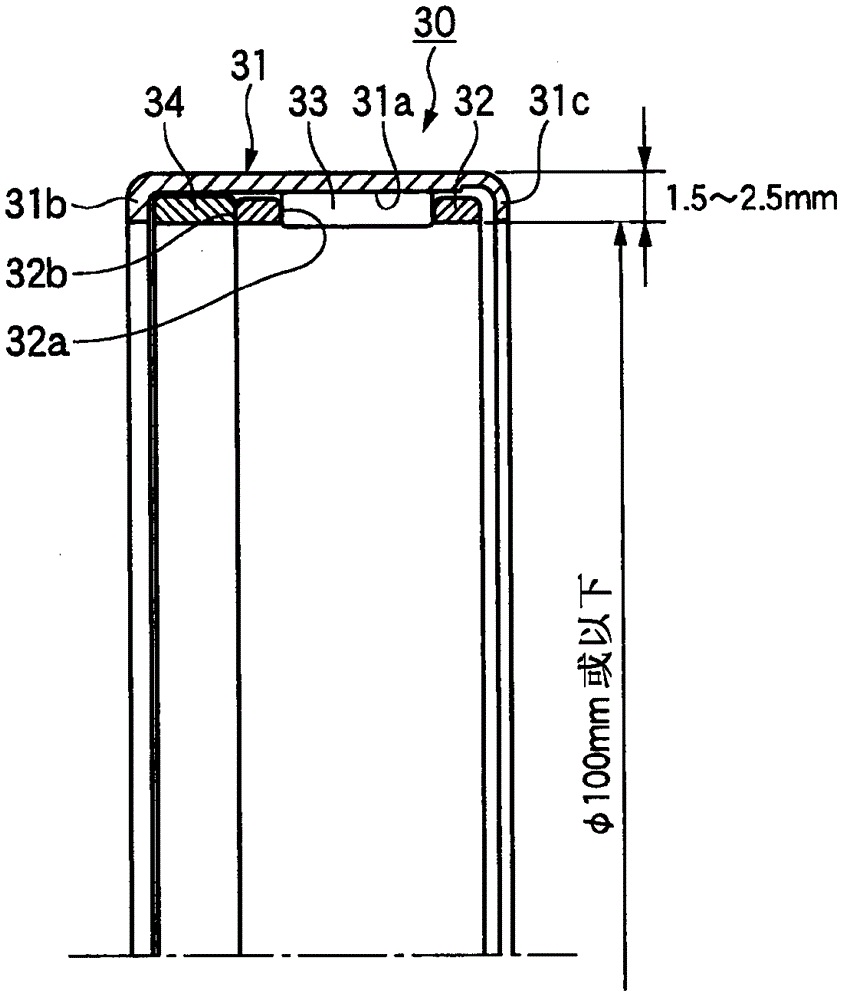

Drawn cup needle roller bearing having a seal ring and its manufacture method

A technology for stamping outer rings and needle roller bearings, which is applied in the direction of needle roller bearings, roller bearings, rolling contact bearings, etc., can solve the problems that the roundness of the inner diameter of the sealing ring and the required precision such as inner diameter tolerance cannot be produced, and achieve low Increased torque, good dimensional accuracy, and anti-wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

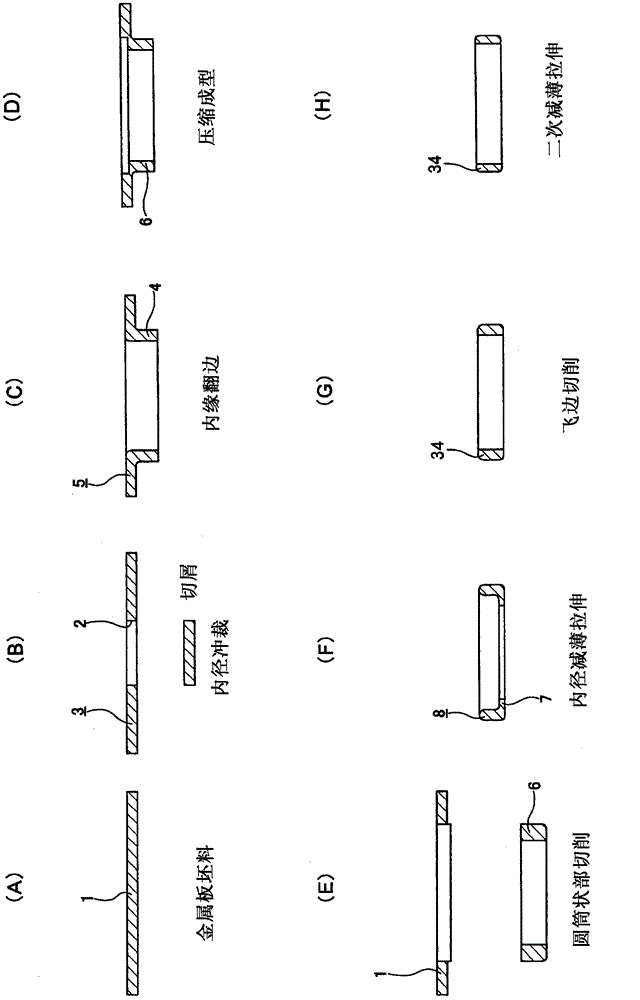

[0069] (Processing method of the first embodiment)

[0070] In the case of this processing method, first, the figure 2 The metal plate 1 shown in (A) as a blank is made of a mild steel plate or a stainless steel plate and is punched to obtain figure 2 (B) The first spare intermediate blank 3 with the circular hole 2 shown. Then, the first spare intermediate blank 3 is subjected to an inner edge flanging process in which the circumference of the circular hole 2 is folded to be at right angles to the above-mentioned metal plate 1 . From the above, we get figure 2 The second spare intermediate blank 5 having the cylindrical portion 4 shown in (C). The volume of the cylindrical portion 4 is larger than the volume of the seal ring to be manufactured. In particular, the length of the cylindrical portion 4 in the axial direction is greater than the length of the seal ring to be manufactured in the axial direction.

[0071] For the cylindrical portion 4 of the above-mentioned ...

no. 2 example

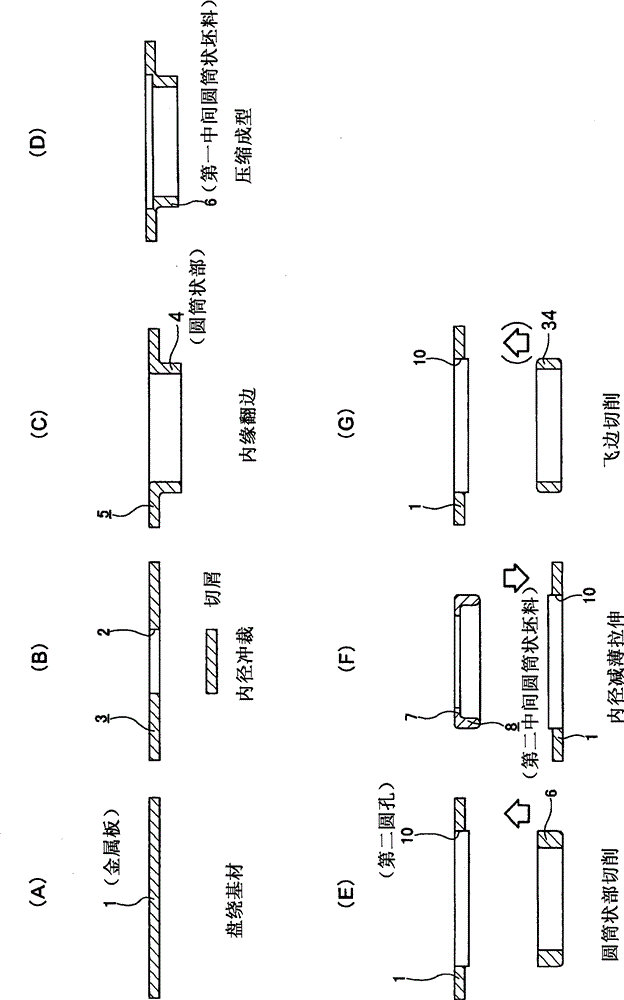

[0080] (The processing method of the second embodiment)

[0081] Figure 3-7 The processing method of the second embodiment is shown. In this case, by sequentially executing the image 3 In the steps shown in (A)→(G), the metal plate 1 is processed into the seal ring 34 . This process is substantially the same as that of the processing method of the first embodiment. In addition, in the case of this example, you can also execute the above-mentioned figure 2 The secondary thinning and stretching process shown in (H). This example is characterized in that, as the above-mentioned metal plate 1, a long metal plate that is sent out from an unshown unwinder and wound up on a not-shown winder is used as the above-mentioned metal plate 1, and the above-mentioned image 3 Steps shown in (A)→(G). That is, in synchronization with the progress of the processing, the above-mentioned elongated metal plate 1 is intermittently sent out at a pitch (interval / pitch=integer) that is balanc...

no. 3 example

[0089] (The processing method of the third embodiment)

[0090] Figure 8 The processing method of the third embodiment is shown. In the case of this example, the Figure 8 In the thinning and stretching process and the back-embedding process shown in (F), the direction in which the second cylindrical intermediate blank 8 is pulled out from the second circular hole 10 of the metal plate 1 and then embedded is relative to the metal plate 1 and the The situation of the processing method of the second embodiment described above is upside down. With reversing the direction, there is no doubt that such Figure 6~7 The structure of the processing device shown varies. Since the structure of other parts is the same as the processing method of the above-mentioned second embodiment, repeated descriptions are omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com