Conical surface friction differential transmission

A transmission, conical surface technology, applied in the direction of friction transmission, transmission parts, belt/chain/gear, etc., can solve the problems of complex processing and manufacturing, and achieve the effect of increasing the equivalent friction coefficient, compensating for wear, and facilitating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

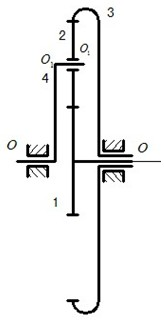

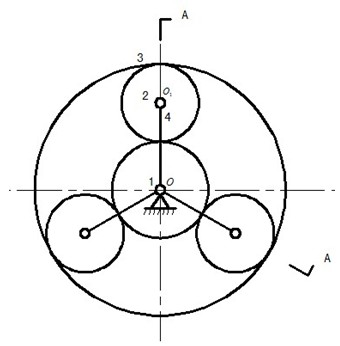

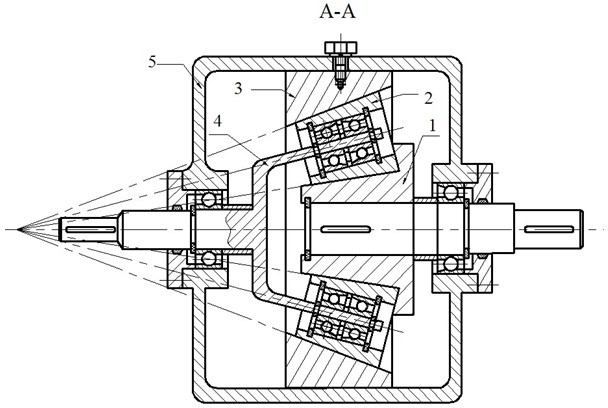

[0018] Such as figure 1 , figure 2 , image 3 As shown, the conical surface friction transmission of the present invention is a differential gear train, including a housing 5, a conical sun gear 1, three identical conical planetary gears 2, a rotating arm shaft and an outer ring 3; Conical sun gear 1, three identical conical planetary gears 2, arm shaft and outer ring 3, conical sun gear 1 is installed at one end of the transmission shaft, the conical sun gear 1 and the transmission shaft are connected by a flat key, and the transmission The other end of the shaft is installed in the bearing hole at one end of the housing 5, supported by angular contact ball bearings to balance the axial load. One end of the rotating arm shaft is installed in the bearing hole at the other end of the shell, and is supported by deep groove ball bearings. There are thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com