Optical axis orientation calibrating method of star sensor probe assembly

A star sensor and optical axis pointing technology, applied in the field of visual measurement, can solve the problems that equipment and software cannot meet the test accuracy requirements, and achieve high work efficiency and high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

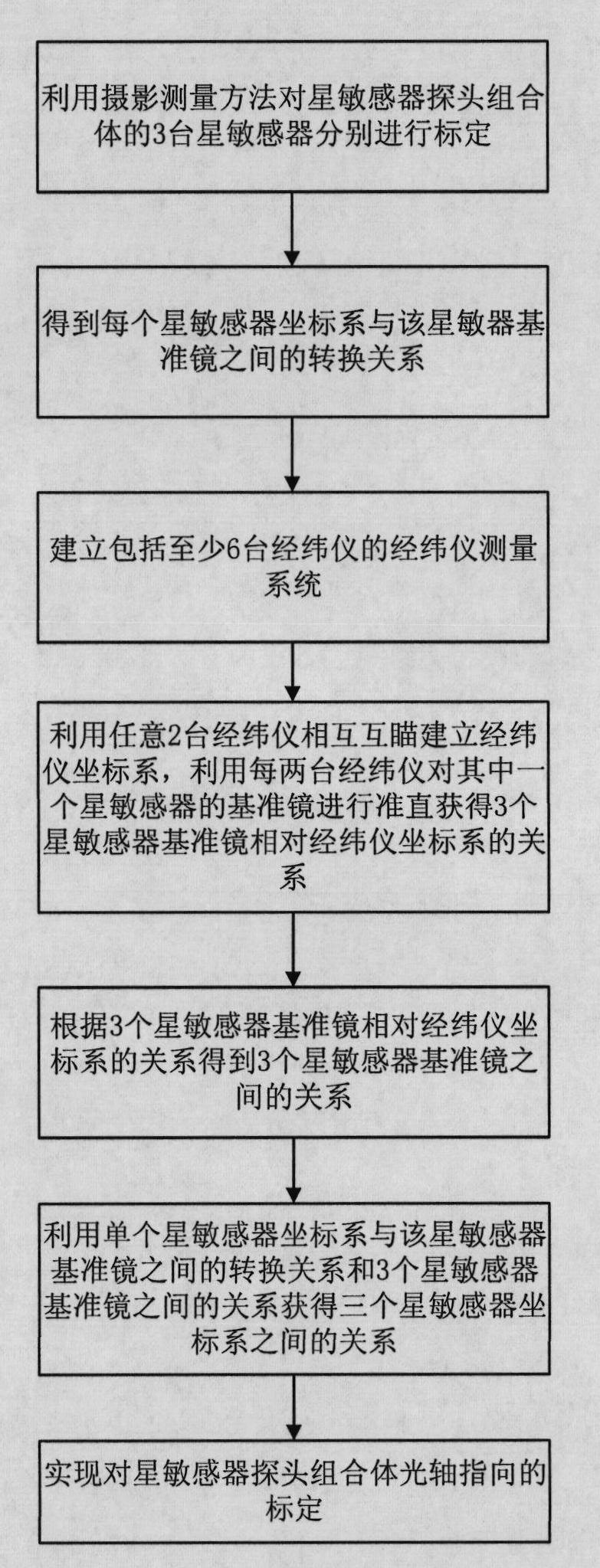

Method used

Image

Examples

Embodiment Construction

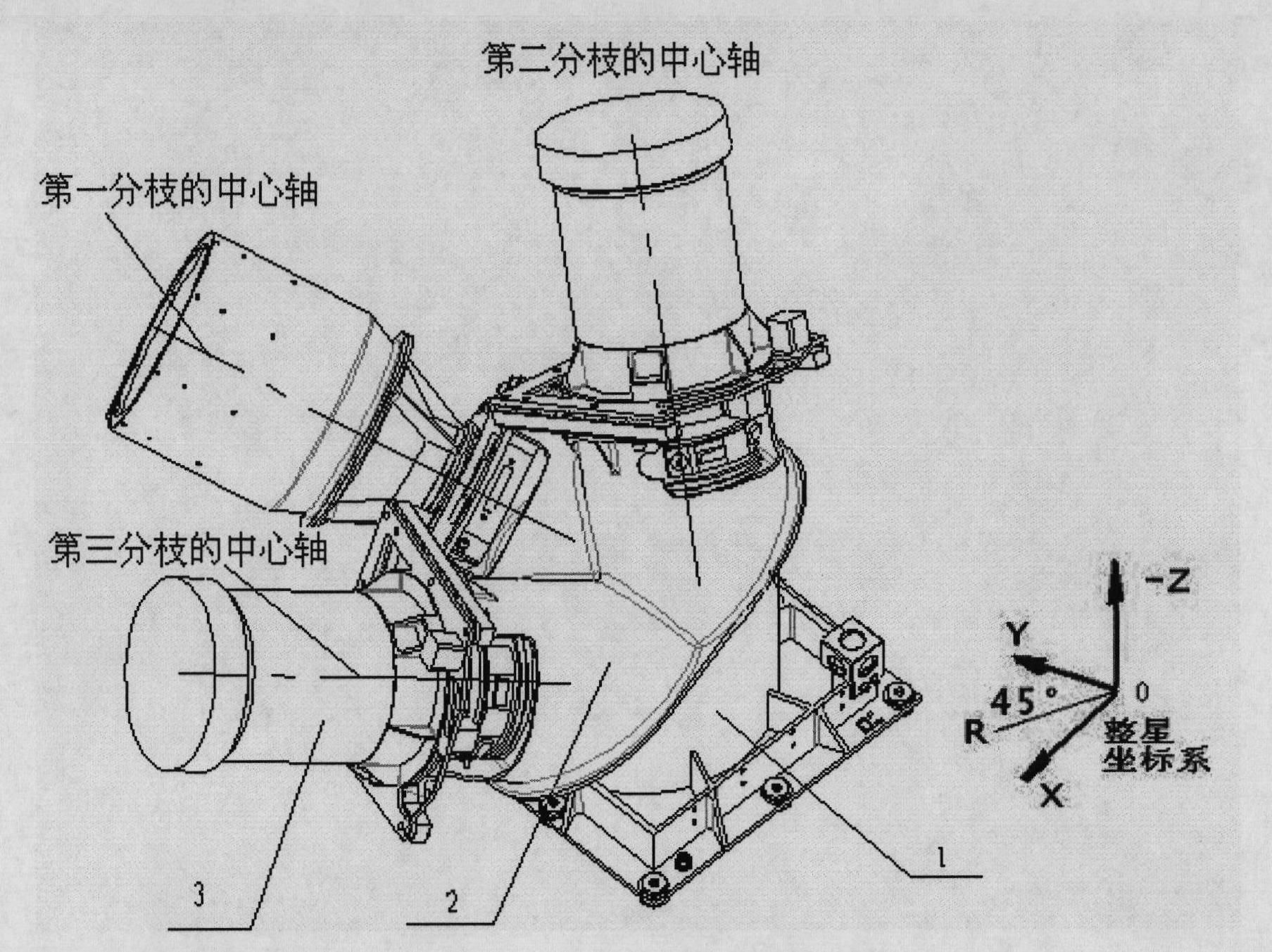

[0034] A star sensor combination such as figure 1 As shown, the star sensor assembly adopts the integrated structure of the three-probe high-precision star sensor 3, the star sensor bracket 2 and the base 1, and the star sensor bracket 2 adopts a dendritic configuration composed of three branches. This configuration reduces the transmission error between the attitude measured by the satellite using the star sensor and the working attitude of the payload, and improves the high stability of the satellite's in-orbit azimuth elements. The star sensor base 1 and the star sensor bracket 2 are integrated by casting or welding, and a star sensor probe 3 is installed on each branch of the star sensor bracket 2 .

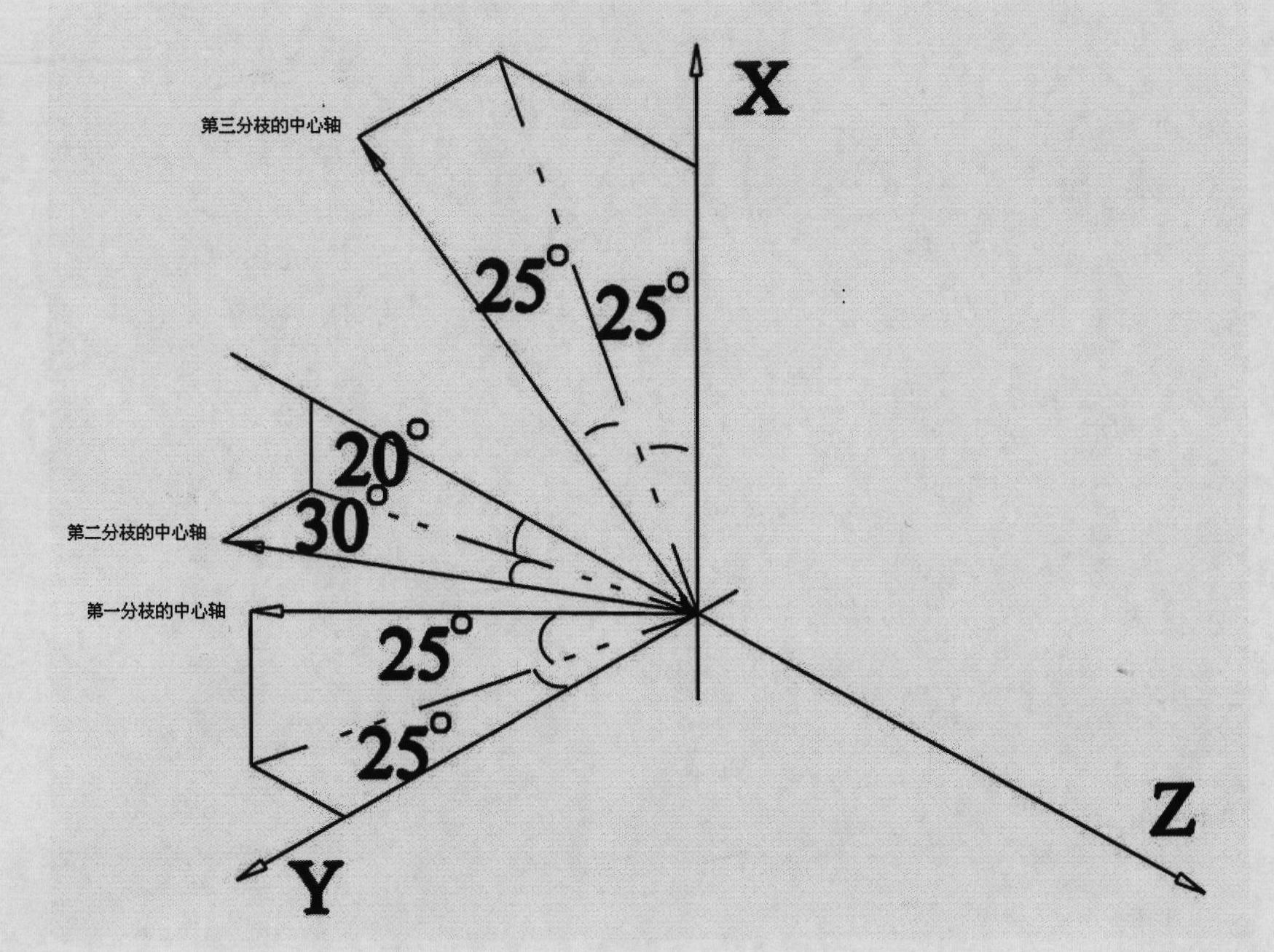

[0035] Star sensor pointing requirements, in order to ensure that the star sensor has a better field of view when it is working in orbit, the optical axis pointing of the star sensor in the whole star coordinate system is designed, as shown in figure 2 As shown, the pointin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com