Test platform for wind power water-cooling device

A technology of water cooling device and test platform, which is applied in measurement devices, electrical program control, instruments, etc., can solve the problems of long time wiring and disconnection, restricting the efficiency of factory debugging, damage to electrical components or test equipment, etc. Short test time, convenient statistics and analysis, to meet the effect of information management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] An embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiment of the present invention is not limited thereto.

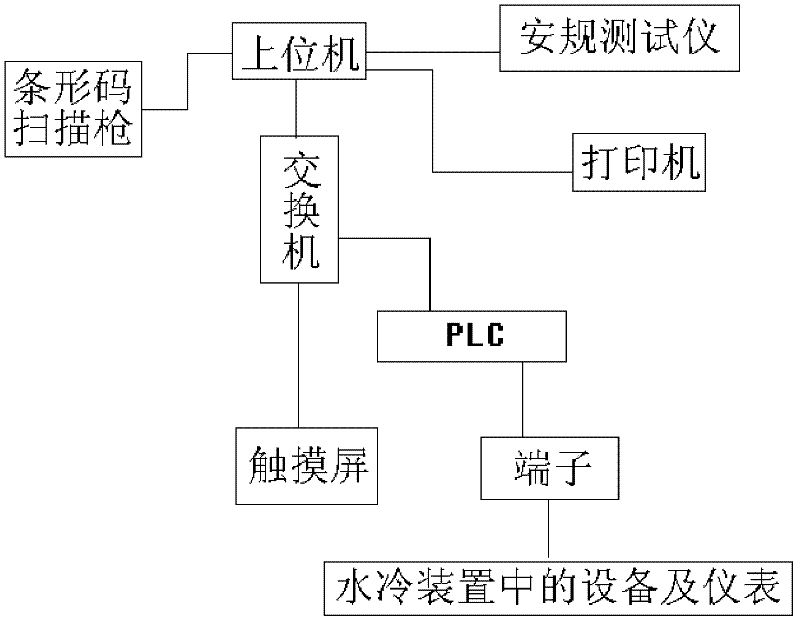

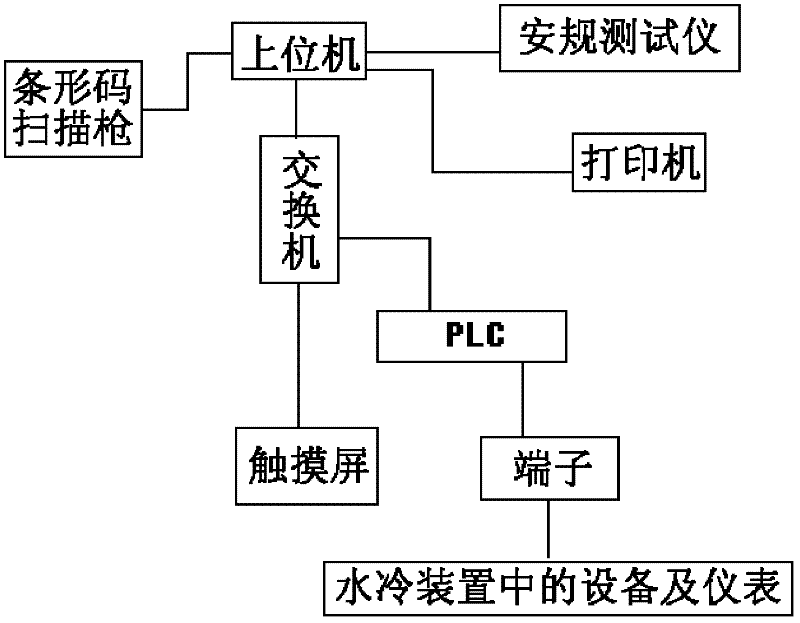

[0045] Wind power water cooling device test platform, such as figure 1 As shown, it includes a host computer, a switch, a PLC, a touch screen and a terminal. The host computer, the PLC and the touch screen are respectively connected to the switch through an Ethernet interface, and the equipment and instruments in the water cooling device are connected to the PLC through the terminals.

[0046] The touch screen sends instructions to the equipment in the water-cooling device through the switch, and the PLC receives the instructions and controls the equipment in the water-cooling device. The PLC collects equipment and instrument information and uploads it to the host computer through the switch. The host computer performs information collection, equipment monitoring and report ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com