Method and device for ageing three-phase rectifier bridges

A technology of three-phase rectification and aging device, which is applied in the direction of electronic circuit testing, single semiconductor device testing, etc. It can solve problems such as circuit failure, three-phase rectifier bridge cannot withstand the impact of a large load, and product reliability cannot be guaranteed. To achieve the effect of ensuring product reliability, simple and flexible use, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment does not serve as any limitation to the present invention.

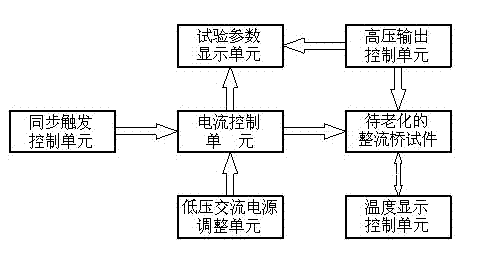

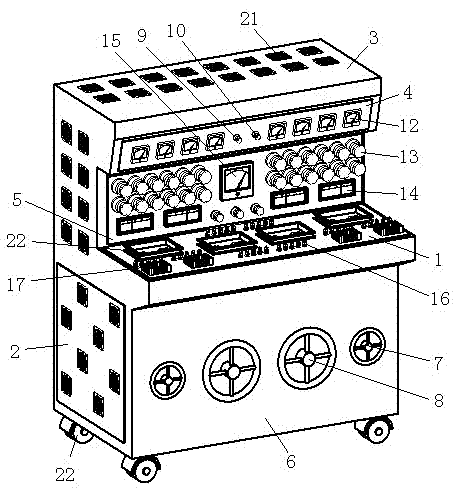

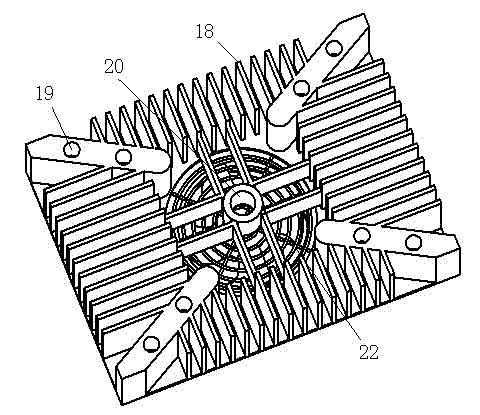

[0026] Example. A kind of aging method of three-phase rectifier bridge, such as figure 1 shown. The method utilizes an aging device to perform batch aging of rectifier bridges; one or more rectifier bridges to be tested are clamped on fixtures in different aging areas of the device, and the terminals of the high-voltage output control unit and current control unit on the device are connected to the terminals to be tested. The rectifier bridge is connected; and the temperature measuring element is fixed on the heat sink in the aging area, the temperature measuring element is connected with the temperature display control unit, the temperature display control unit is connected with the cooling fan unit; the current control unit and the high voltage output control unit are respectively connected with the test parameters The display unit is connected; the current control unit is respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com