Method and device for removing jacket layer of optical fiber

A technology for optical fiber sheath and sheath layer is applied in the field of removing the polymer sheath layer of silica optical fiber, which can solve the problems of large adhesion force of the sheath layer, large force applied to the optical fiber, low qualification rate, etc., so as to improve labor productivity, Simple structure and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

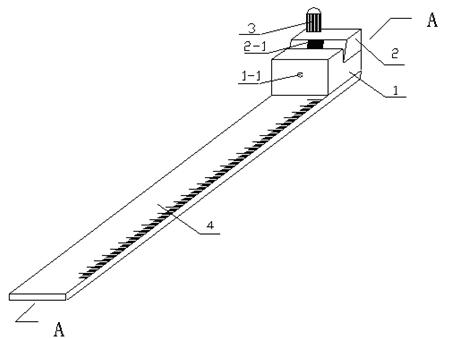

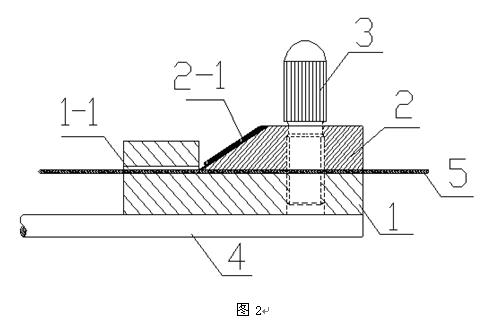

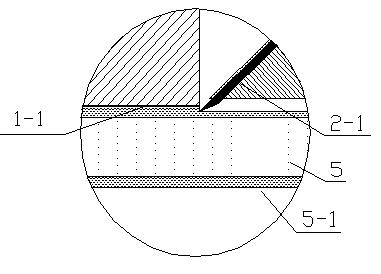

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] like Figure 1-5 As shown, the present invention comprises base 1, adjustable knife rest 2, locking bolt 3, scale 4; Feed trough 1-2; feed trough 1-2 is connected to the through hole 1-1; the scale 4 is fixed on the bottom of the base 1, and its zero position is connected to the through hole 1-1 and the feed trough 1-2 Flat; the adjustable knife holder 2 is equipped with a planer 2-1, the adjustable knife holder 2 is located on the upper part of the base 1, the upper end of the planer 2-1 is connected to the bracket, and the edge of the lower end is aligned with the through hole 1-1 and the feed chute 1-2, the planer 2-1 and the feeding trough 1-2 are inclined; The base 1 is threaded.

[0023] When in use, turn the locking bolt 3 counterclockwise to loosen the contact between the adjustable tool holder 2 and the base 1, so that the edge of the planer 2-1 can move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com