Double-platform structure of ACF (Anisotropic Conductive Film) and MB (Main Bonding) in fully-automatic COG (Chip on Glass) bonder

A bonding machine, fully automatic technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of increasing the debugging time of the whole machine, high production cost, unstable mechanical structure, etc., and achieves convenient debugging and compact installation structure , The effect of mechanical structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

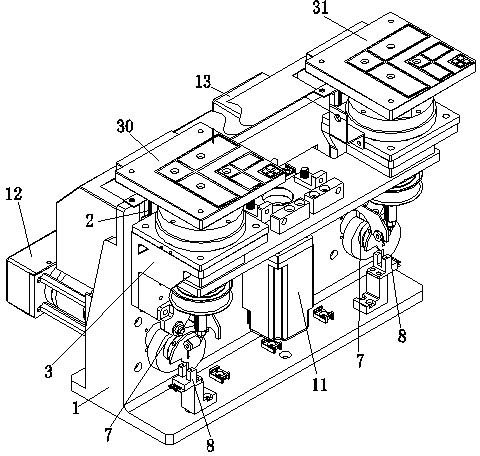

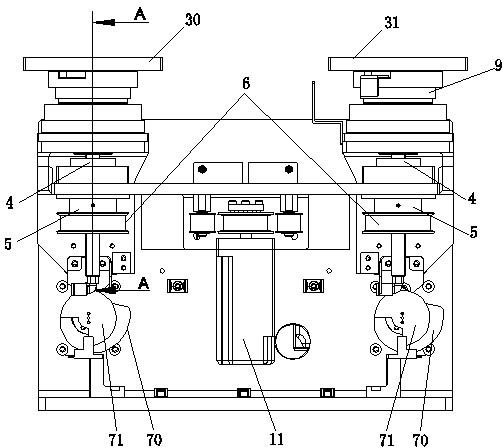

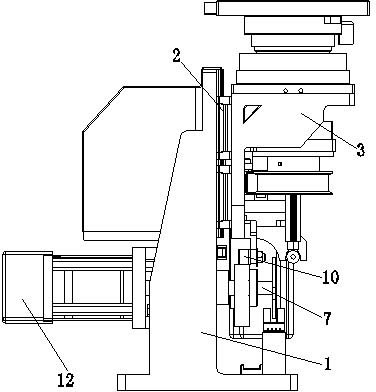

[0017] see figure 1 , figure 2 with image 3 , the embodiment of the present invention includes: a double-platform structure of ACF and MB units in a fully automatic COG bonding machine, including a frame 1, a linear guide rail 2 and an installation panel 3, and the installation panel 3 includes a first platform 30 and a second platform 30. Two platforms 31, two ball guide shaft sets 4, two vertical rotation shafts 5 and a pair of synchronous pulleys 6, the first platform 30 and the second platform 31 pass through two ball guide shaft sets 4 and two vertical rotation shafts 5 The rotation is driven by a pair of synchronous pulleys 6, and two h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com