Positioning system and positioning method for multi-station tube conveying transition vehicle on steel tube production line

A positioning system and traversing car technology, applied in the field of multi-station pipe traversing car positioning system for steel pipe production lines, can solve the hidden dangers of operator and equipment safety, absolute value encoder and high-speed counting module are expensive and prone to errors. and other problems, to achieve the effect of improving positioning accuracy and work efficiency, simplifying programming and debugging, and simplifying speed setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

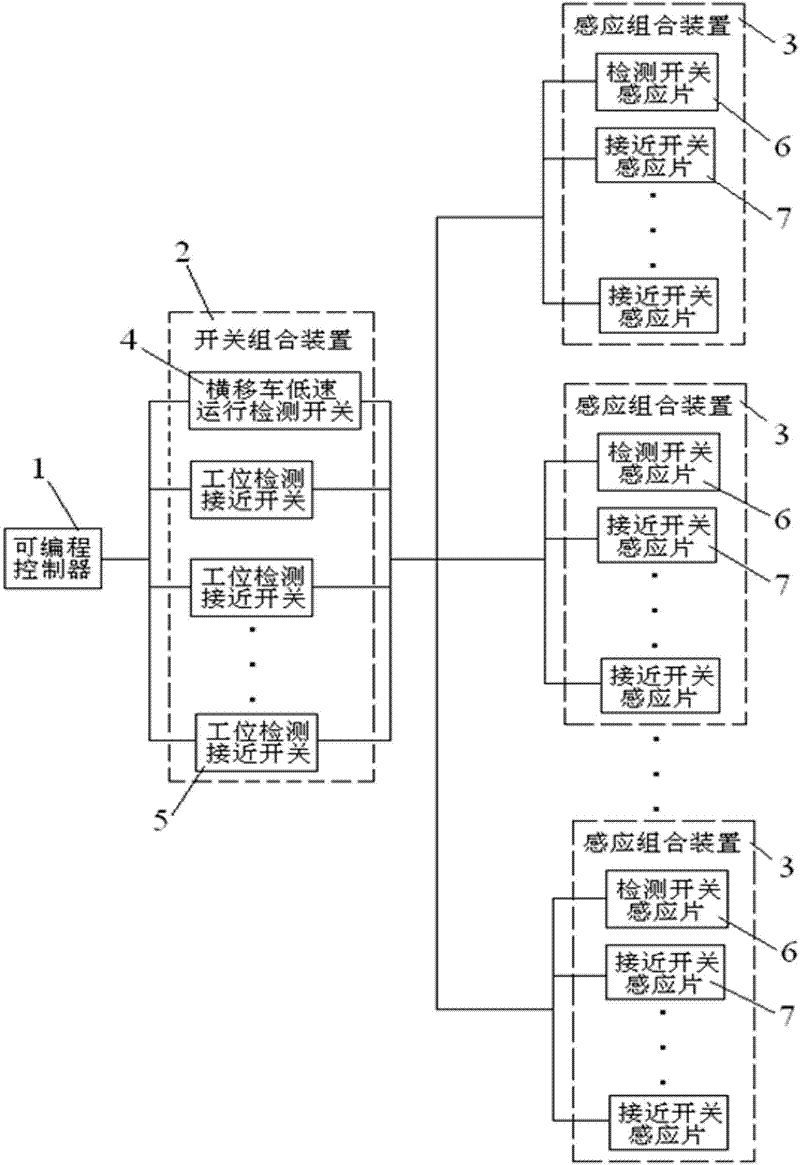

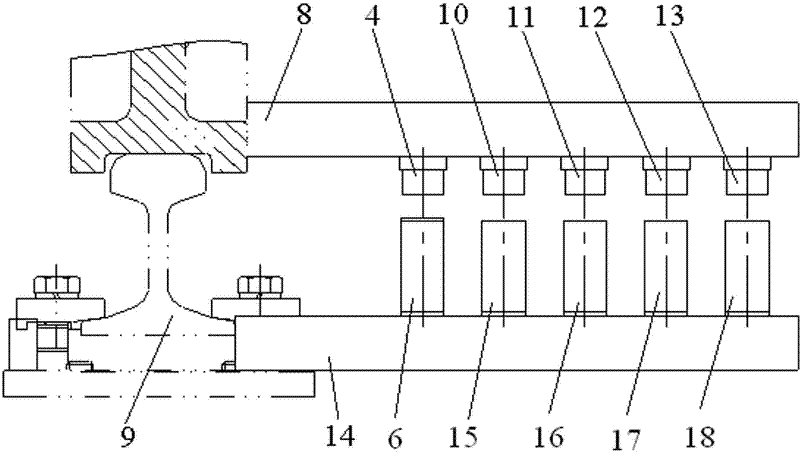

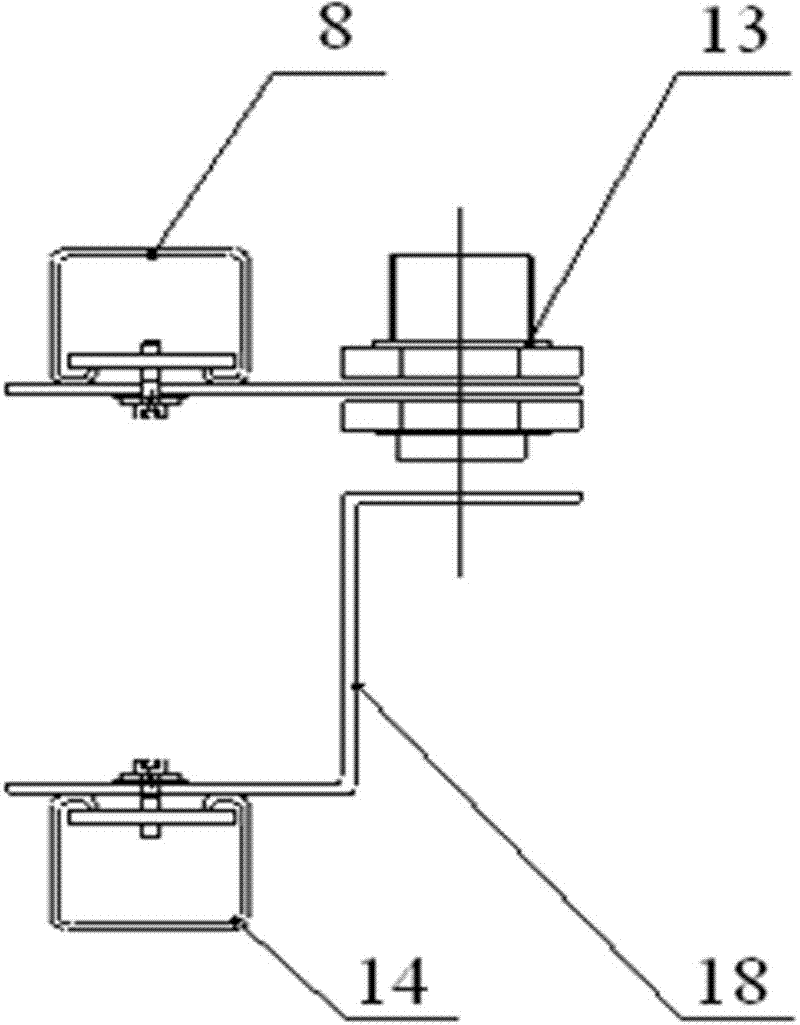

[0035] The positioning system of the existing steel pipe production line multi-station transport pipe traverse vehicle uses a high-speed counting module and an absolute value encoder. Due to the influence of mechanical installation accuracy, control system accuracy and many other aspects, errors are easily generated. Accumulated errors lead to inaccurate positioning, causing system malfunctions, posing serious safety hazards, and increasing equipment costs and the workload of design and commissioning personnel. In order to overcome the problems existing in the prior art, the present invention provides a relatively simple, reliable and low-cost structure such as figure 1 The shown positioning system for transporting and traversing vehicles includes a programmable controller 1, and the programmable controller 1 is connected to a switch combinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com