Square-outside circular-inside cavity oil expansion tank for transformer of locomotive

A technology of oil expansion tank, outer square and inner circle, which is applied in the direction of transformer/inductor cooling, etc., can solve the problems of limited utilization of cooling tower space, offset of cooling tower frame center of gravity, and low rigidity of oil expansion tank, etc., to achieve Improved operation and maintenance performance, improved structural rigidity, and a reasonable center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

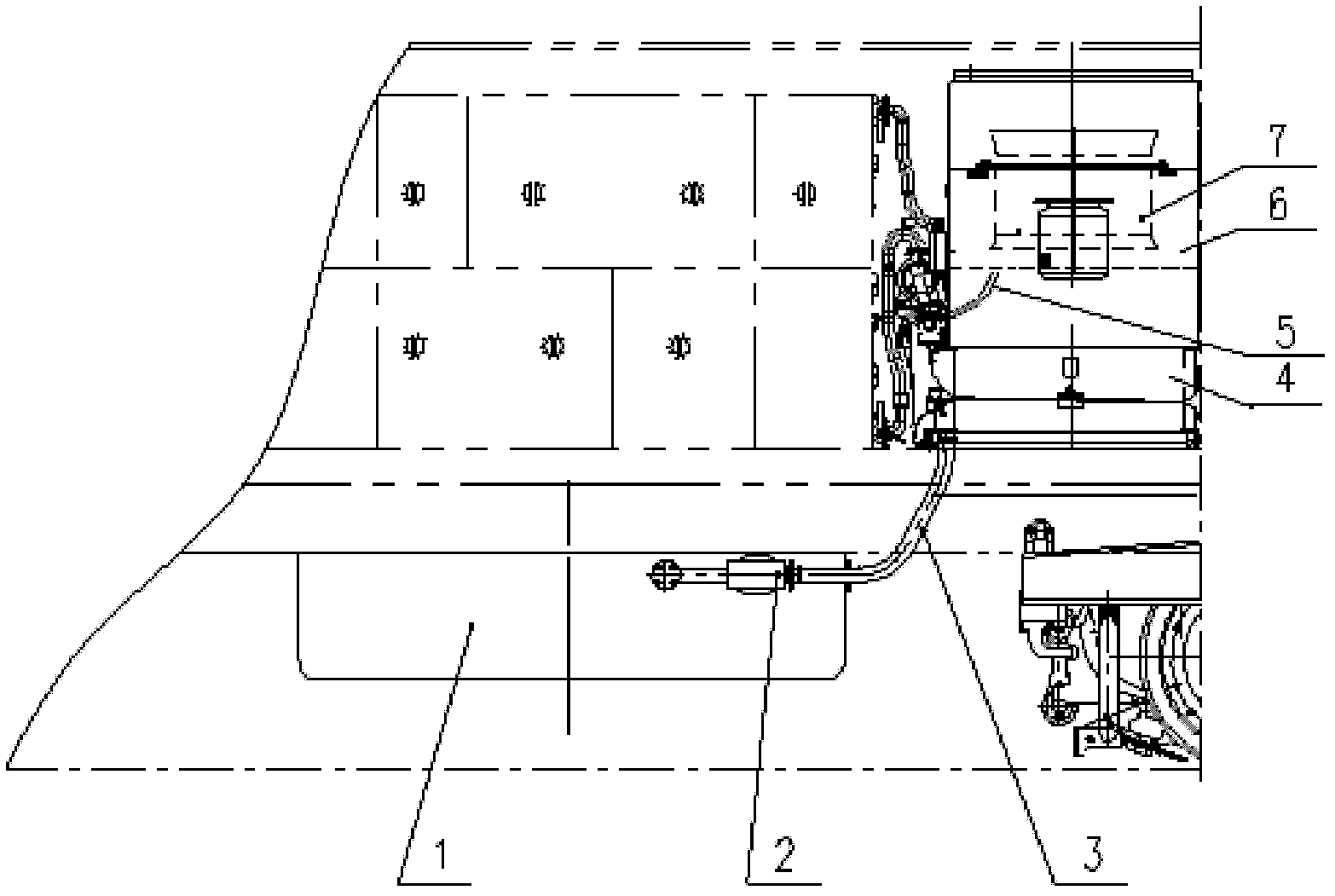

[0018] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. A transformer oil expansion tank device with an outer square inner circle chamber for a locomotive includes a transformer 1, an oil pump 2, a metal hose 3, a radiator 4, a buffer oil pipe 5, and an oil expansion tank. Box 6 and blower fan 7 are characterized in that:

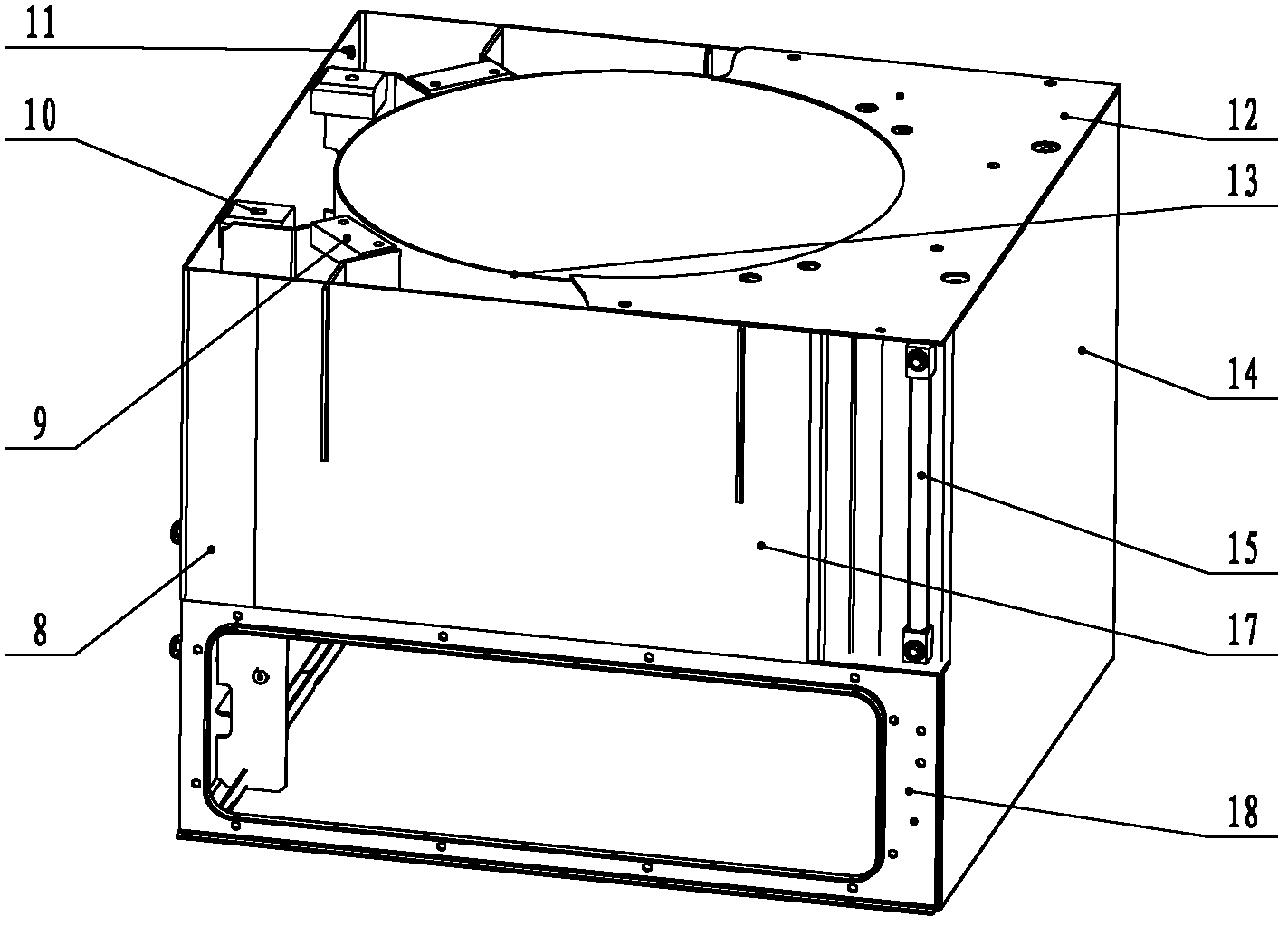

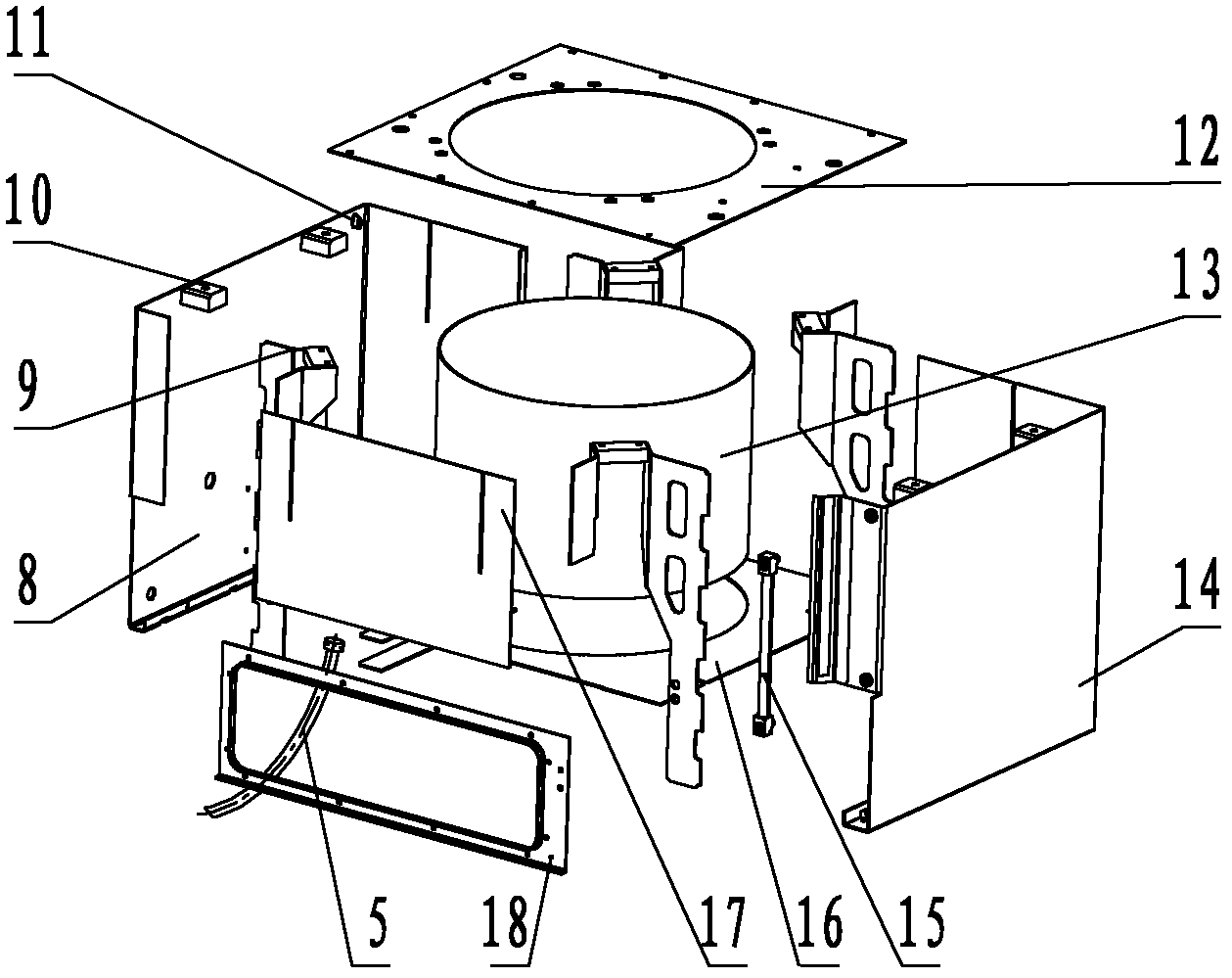

[0019] The oil expansion tank 6 is an outer square inner circle chamber structure, that is, the oil expansion tank 6 is welded into a closed ring cavity container by a left plate 8, a top plate 12, an inner cylinder 13, a right plate 14, a bottom plate 16, and a front plate 17 To constitute the main body of the oil expansion tank, four sets of fan brackets 9 for connecting the fan 7, four sets of lifting nuts 10 for loading and unloading the entire cooling tower and a set of oil level display tubes (15) are welded in the oil expansion tank 6; The oil expansion tank (6) originally arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com