Method for manufacturing transparent silicon-based substrate with integrated circuit (IC) device

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of large module volume, complex optical path structure, and reduced light utilization rate of the optical path, and achieve simple structure, simple optical path, and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

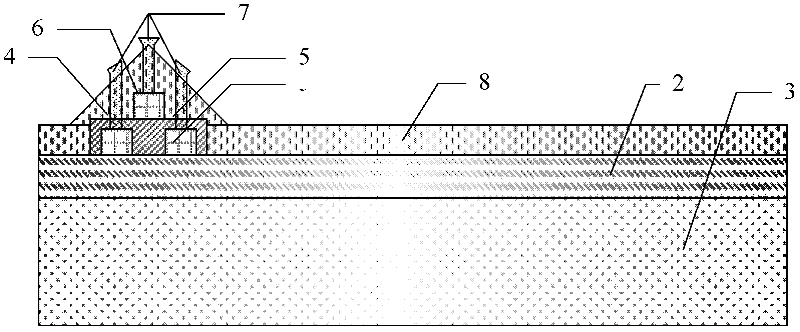

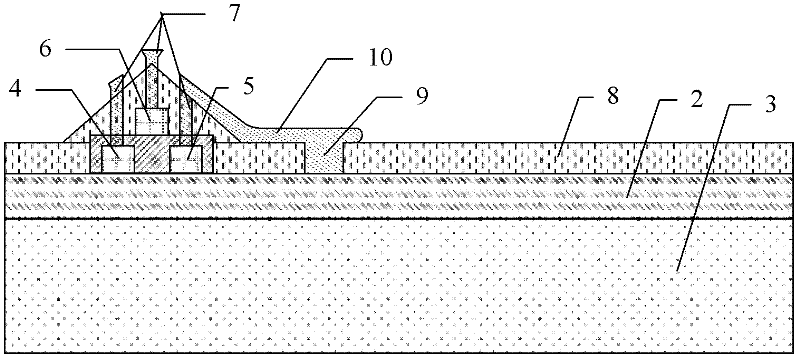

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] Such as Figure 1-8 shown.

[0039] A method for manufacturing a transparent silicon-based substrate with an IC device, comprising the following steps:

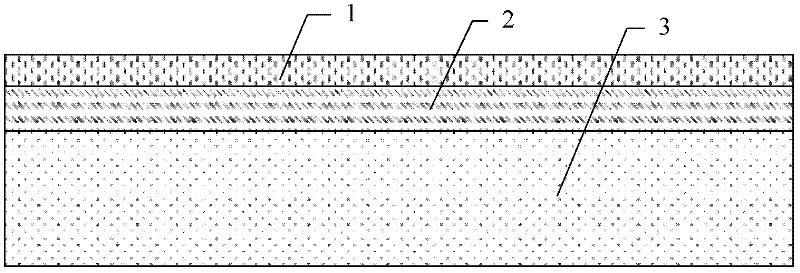

[0040] 1) Select a silicon-on-insulator (SOI, SILICON ON INSULATOR) as the substrate for making IC devices. The silicon-insulator is composed of a substrate silicon layer 3, a silicon dioxide insulating layer 2, and a device silicon layer 1. The device silicon layer 1 Located on the top layer, the silicon dioxide insulating layer 2 is located between the substrate silicon layer 3 and the device silicon layer 1;

[0041] To make transparent silicon-based substrates, general bulk silicon cannot meet the requirements, and special silicon wafers are required. This invention uses SOI (SILICON ON INSULATOR) insulating silicon wafers, which are devices made of substrate silicon, silicon dioxide insul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap