Method for manufacturing mercury-free and lead-free button battery

A button battery and manufacturing method technology, applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of increased production costs, poor negative electrode cover plating, continuous discharge safety, etc., to avoid pollution and eliminate potential safety hazards , good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

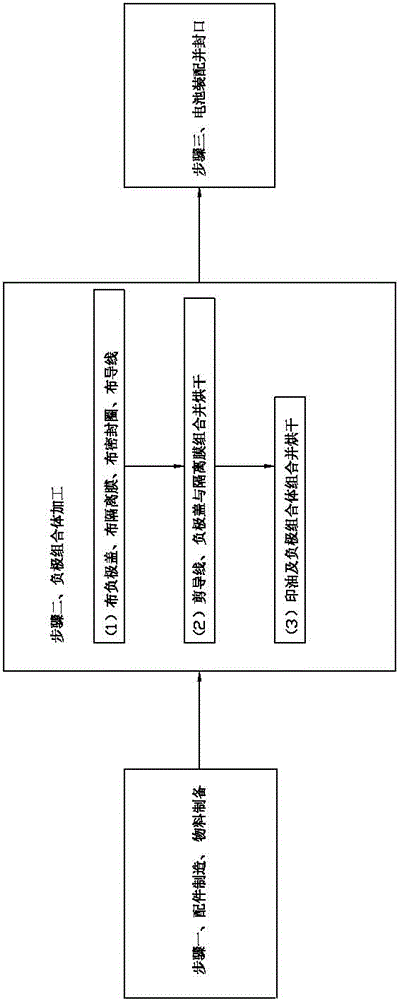

Method used

Image

Examples

Embodiment Construction

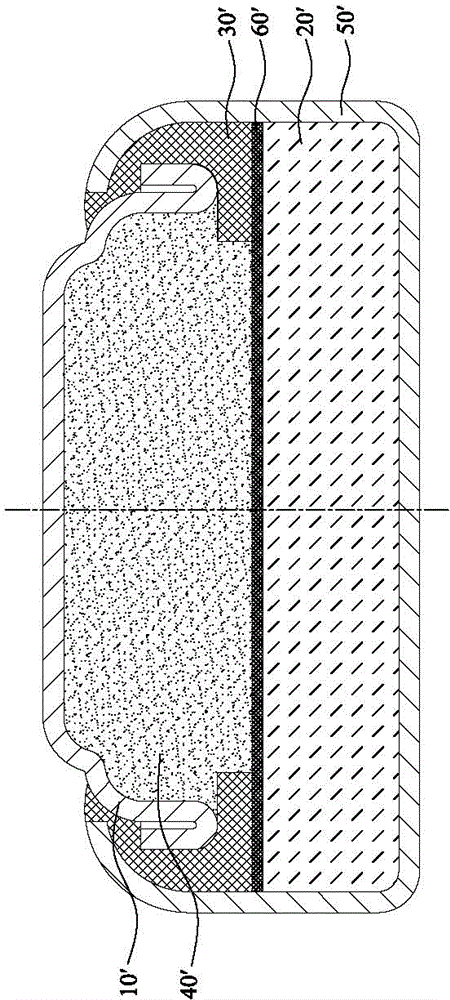

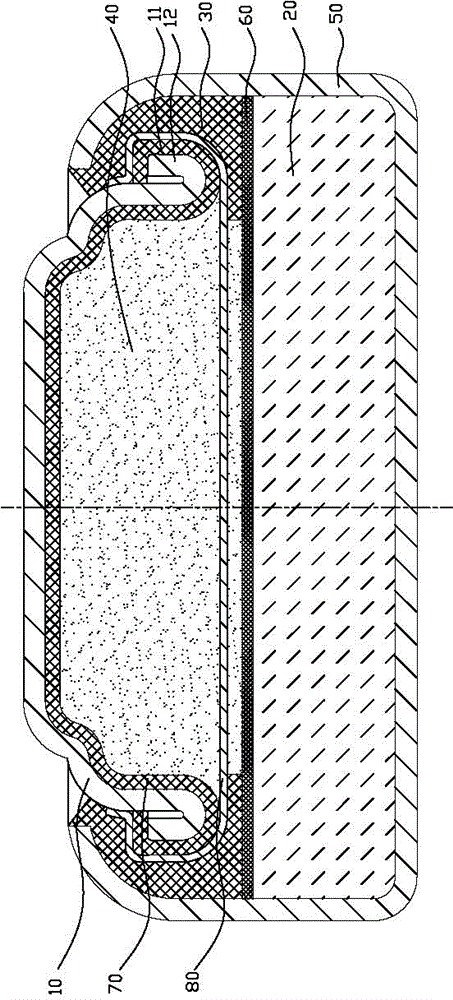

[0078] Please refer to figure 2 As shown, it has shown the specific structure of the button battery of the present invention, including a negative electrode cover 10, a positive electrode material 20, a sealing ring 30, a negative electrode material 40, a positive electrode case 50, a positive electrode material 20 for isolating and a separator 60 for the negative electrode material 40 , a separator 70 for isolating the negative electrode cover 10 and the negative electrode material 40 , and a conductive wire 80 connected between the negative electrode cover 10 and the negative electrode material 40 . The positive electrode case 50 and the negative electrode cover 10 are fastened and connected; the sealing ring 30 is sandwiched between the positive electrode case 50 and the negative electrode cover 10 to isolate the positive electrode case 50 and the negative electrode cover 10 from each other; the positive electrode material 20 is arranged on the positive electrode case 50, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com