Preparing method of metamaterials

A technology of metamaterials and dielectric materials, applied in the field of metamaterials, can solve the problems that the conduction loss is not applicable to infrared and optical frequency bands, and can not realize negative refractive index relatively freely, and achieve the effect of negative refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

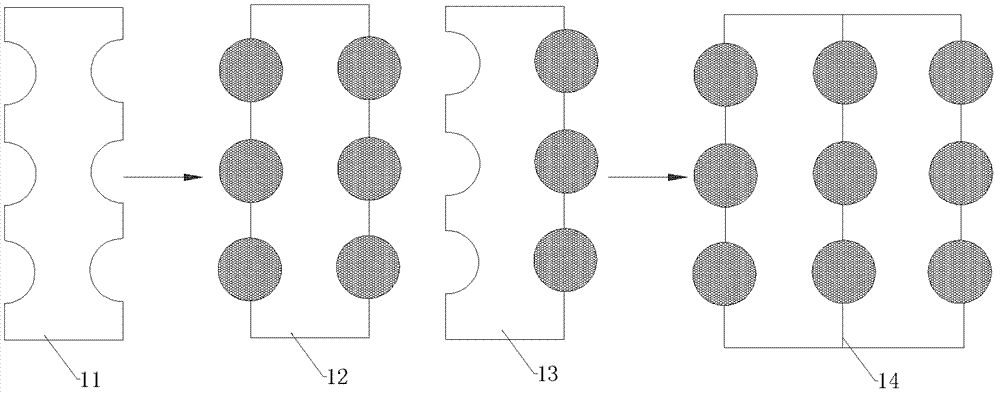

Image

Examples

Embodiment 1

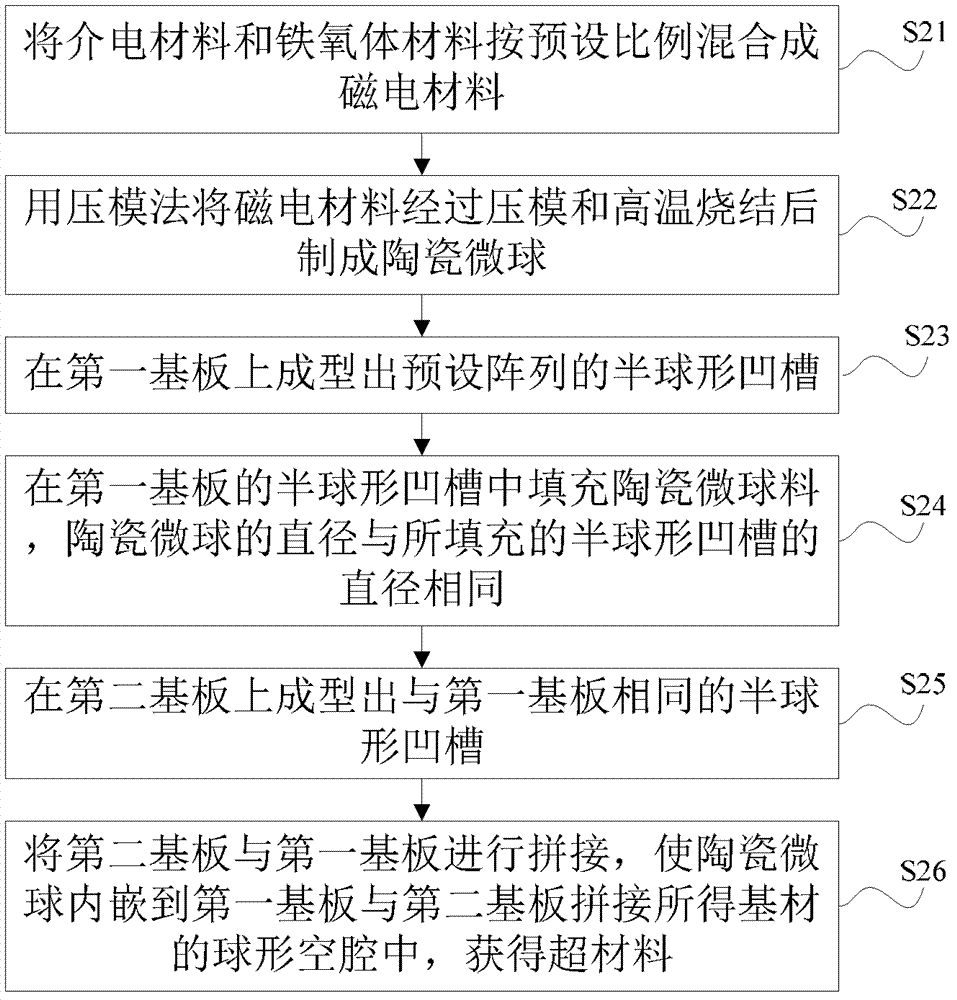

[0024] see figure 2 , is a flowchart of a method for preparing a metamaterial provided in Embodiment 1 of the present invention, and the method includes:

[0025] S21: Mixing the dielectric material and the ferrite material according to a preset ratio to form a magnetoelectric material. The ratio of the specific dielectric material and ferrite material can be obtained according to the effective electromagnetic parameter logarithmic calculation formulas (1) and (2) of the composite medium:

[0026] lnε=v 1 lnε 1 +v 2 lnε 2 (1)

[0027] lnμ=v 1 lnμ 1 +v 2 lnμ 2 (2)

[0028] Where ε, μ are the permittivity and permeability of the hybrid magnetoelectric material, ε 1 , μ 1 is the permittivity and permeability of the dielectric material, ε 2 , μ 1 is the permittivity and permeability of ferrite, v 1 , v 2 is the volume ratio of dielectric material to ferrite and v 1 +v 2 =1.

[0029] For example, the dielectric constant of the substrate material is 2.8, and...

Embodiment 2

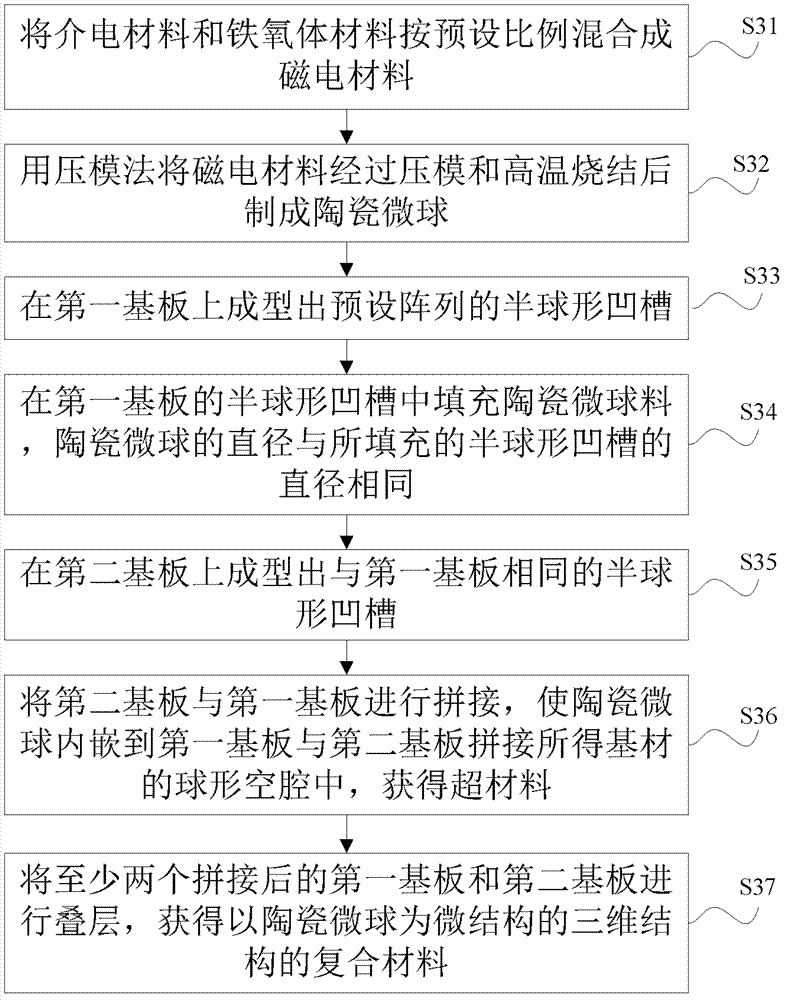

[0041] see image 3 , is a flowchart of a method for preparing a metamaterial provided in Embodiment 2 of the present invention, and the method includes:

[0042] S31 to S36 in this embodiment are the same as S21 to S26 in Embodiment 1, and will not be repeated here. On the basis of Embodiment 1, this embodiment also includes:

[0043] S37: Laminating at least two spliced first substrates and second substrates to obtain a composite material with a three-dimensional structure with ceramic microspheres as microstructures.

[0044] Specifically, at least two spliced first substrates and second substrates can be laminated by using an adhesive to obtain a three-dimensional composite material with ceramic microspheres as microstructures.

[0045] Wherein, the dielectric constant of the ceramic microsphere is greater than that of the second substrate material.

[0046] In this embodiment, the spherical cavity obtained by splicing the first substrate and the second substrate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com