Method for improving light extraction efficiency of LED by using nanoscale ZnO

A light extraction efficiency, nano-scale technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of complex process, pollution of LED production line, high production cost, etc., and achieve the effect of broad application prospects, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples and with reference to the accompanying drawings, but the present invention is not limited to the following examples. The nanoscale ZnO roughness was tested by SEM and AFM.

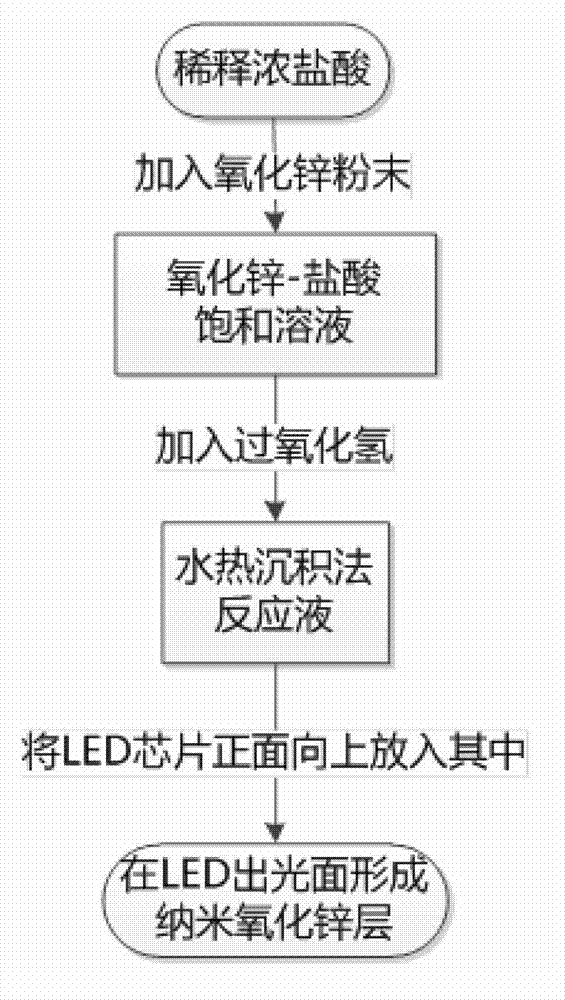

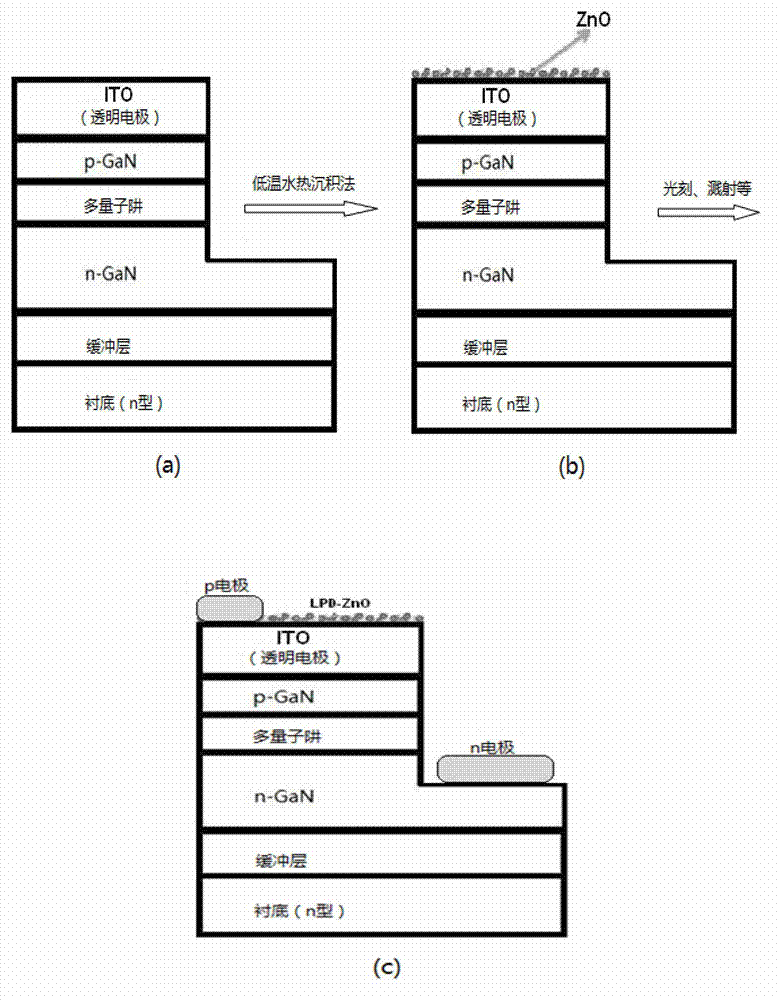

[0029] Such as figure 1 as shown, figure 1 It is a flow chart of the method for enhancing LED light extraction efficiency provided by the present invention. Through this method, the upper surface of the window layer of the LED can be roughened at the nanometer level, thereby achieving the purpose of improving the LED light extraction efficiency. The method includes:

[0030] Step 1: Prepare the reaction solution - dilute 12mol / L (36-38%) concentrated hydrochloric acid to 1.72mol / L with deionized water; add ZnO powder (analytical pure) to the diluted hydrochloric acid at room temperature and stir until s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com