Externally rotating stator and manufacturing method thereof

A production method and technology for outer rotors, which are applied in the manufacture of stator/rotor body, magnetic circuit shape/pattern/structure, and winding insulation shape/pattern/structure, etc. The effect of working noise and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

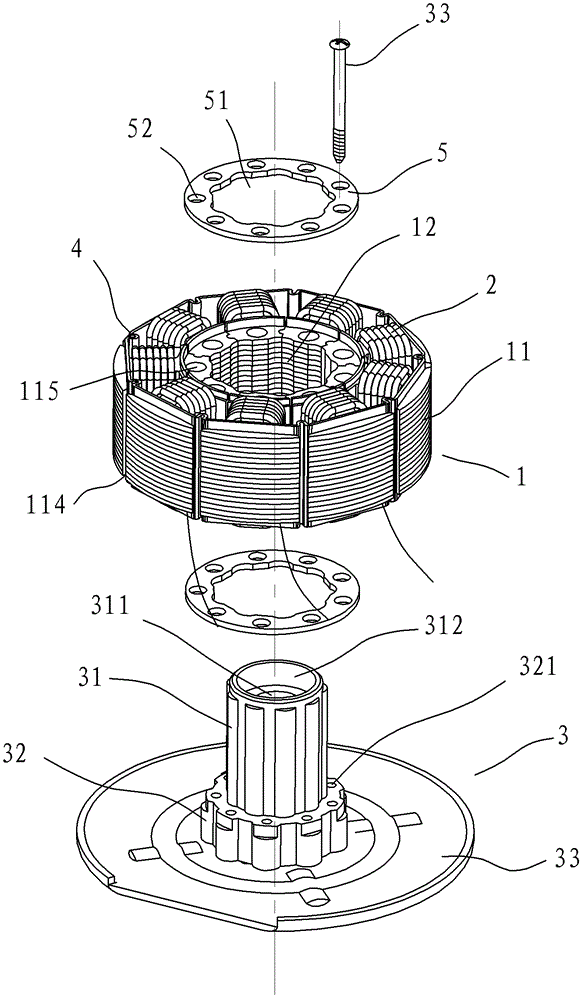

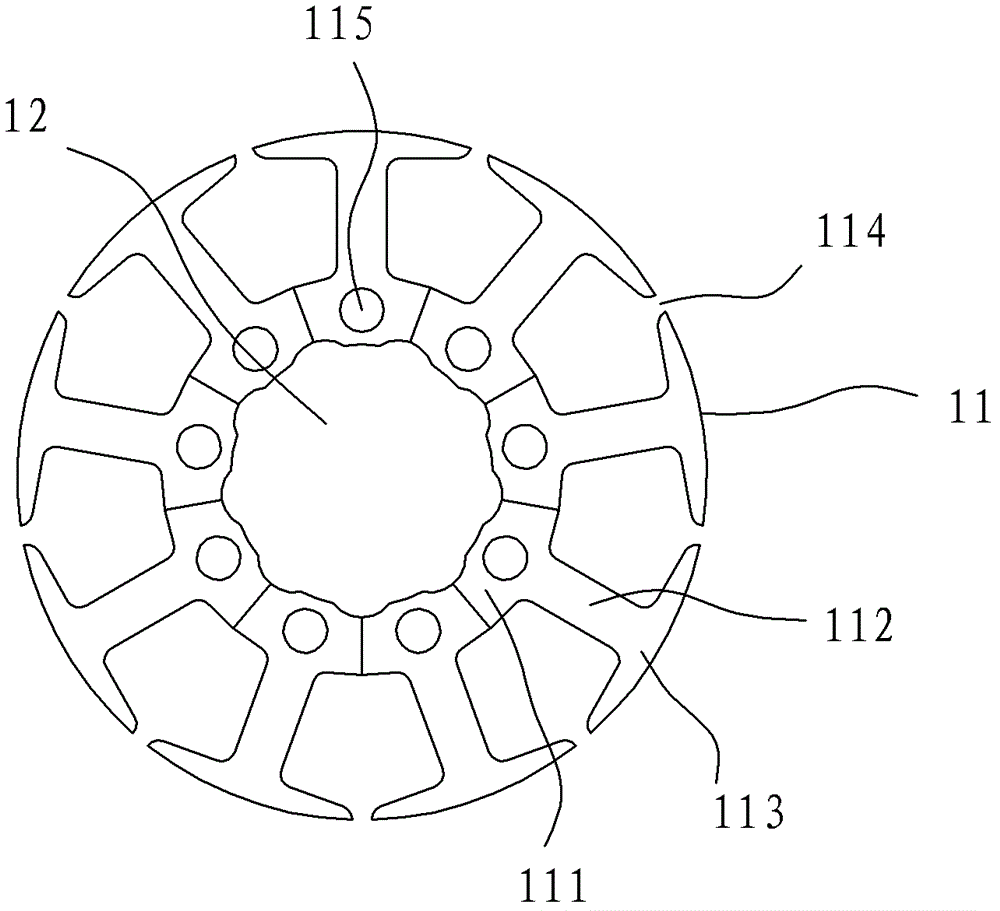

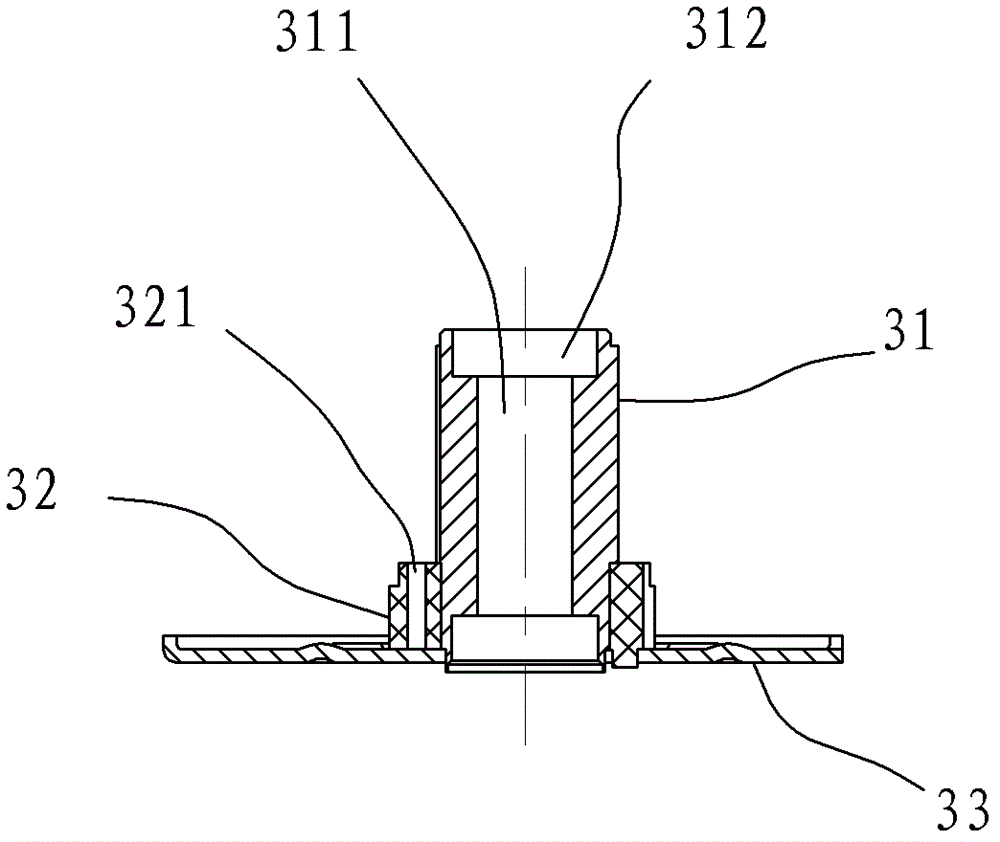

[0038] as attached figure 1 As shown, an outer rotor type stator proposed by the present invention includes a stator core 1 formed by stacking silicon steel sheets, a stator winding 2 wound on the stator core 1 and a stator for fixing the stator core 1 The stator seat 3. Among them, the stator core 1 is composed of a plurality of I-shaped independent stator teeth 11 arranged in a ring, and "independent" here means that each stator tooth 11 is an independent unit processed separately to form a stator tooth The silicon steel sheets of the stator teeth are not connected with the silicon steel sheets of other stator teeth. The position of the stator teeth 11 is fixed by the stator base 3 . For further refinement, refer to figure 2 The stator teeth 11 include, from the inside to the outside, a base 111 constituting the central hole 12, a tooth 112 for winding wires, and a magnetic pole 113, and two adjacent stator teeth 11 are also provided with gaps 114 facing the outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com