Dual-stator brushless double-fed motor

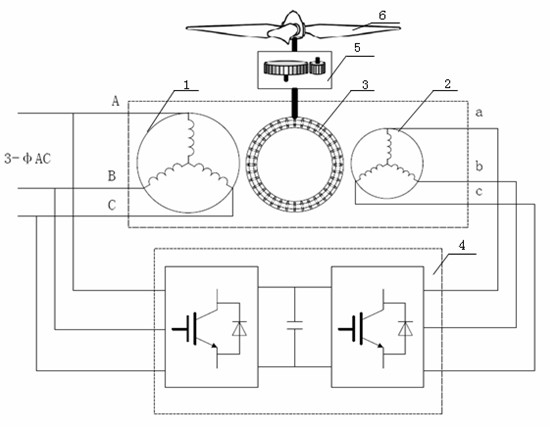

A doubly-fed motor and double-stator technology, applied to electrical components, electromechanical devices, etc., can solve the problems of special squirrel-cage rotor structure, low utilization rate of common rotors, and large space occupied by the system, achieving compact structure and improving space utilization and power density, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

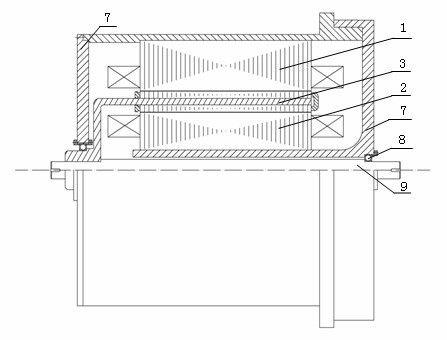

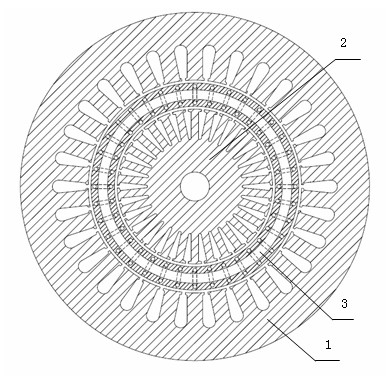

[0030] The dual-stator brushless doubly-fed motor of the present invention includes a bidirectional rectifier inverter 4, an end cover 7, a rotating shaft 9, an inner stator 2, a rotor 3 surrounding the inner stator 2, an outer stator 1 surrounding the rotor 3, and the rotating shaft 9 and The end covers 7 are connected by bearings 8, and one end of the rotor 3 is connected to the rotating shaft 9, and an air gap is provided between the two stators and the rotor 3; the outer stator 1 includes an outer stator core 11 and is arranged on the outer stator core 11. The outer stator winding 12 with an upper pole number of 2p, the inner stator 2 includes an inner stator core 21 and an inner stator winding 22 with a pole number of 2q arranged on the inner stator core 21, the outer stator winding 12 and the inner stator winding 22 are both Multi-phase symmetrical stator winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com