Rotor position detection device for permanent magnet motor

A technology of rotor position detection and permanent magnet motor, applied in electromechanical devices, electrical components, etc., can solve problems such as increased cost, disadvantageous motor structure optimization, increased axial space, etc., and achieves strong induction capability, simple and reasonable structure, and applicable scope. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

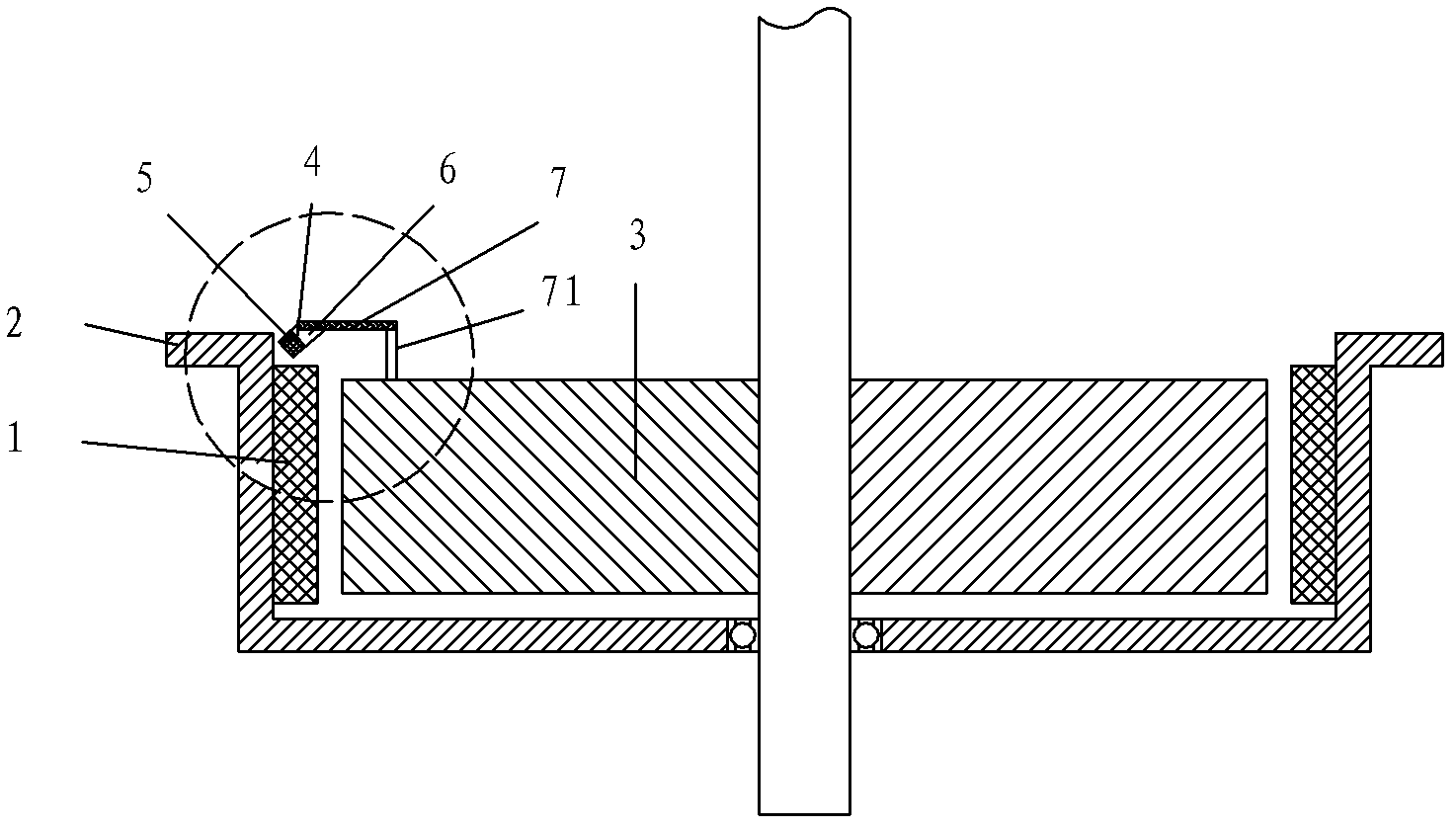

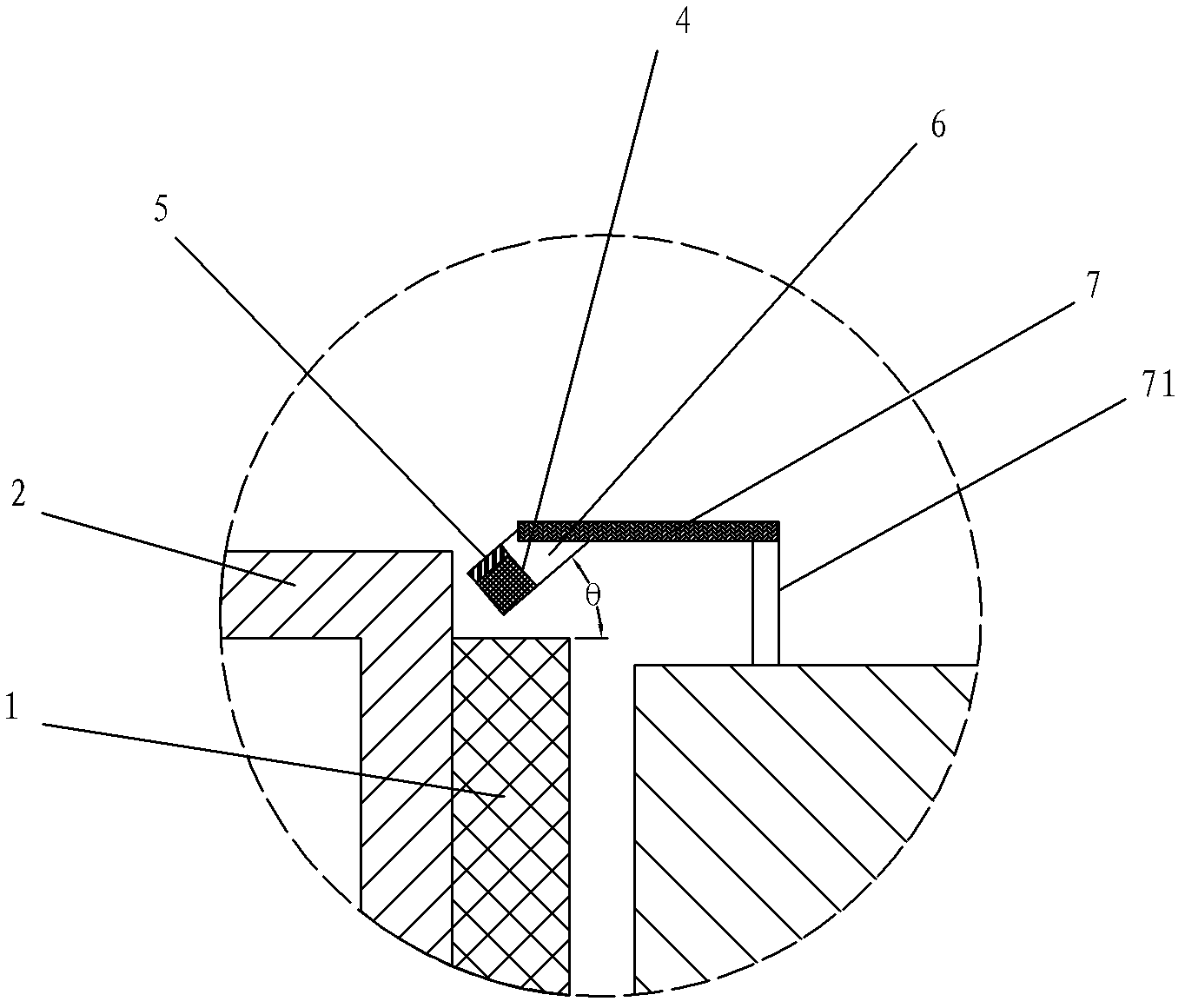

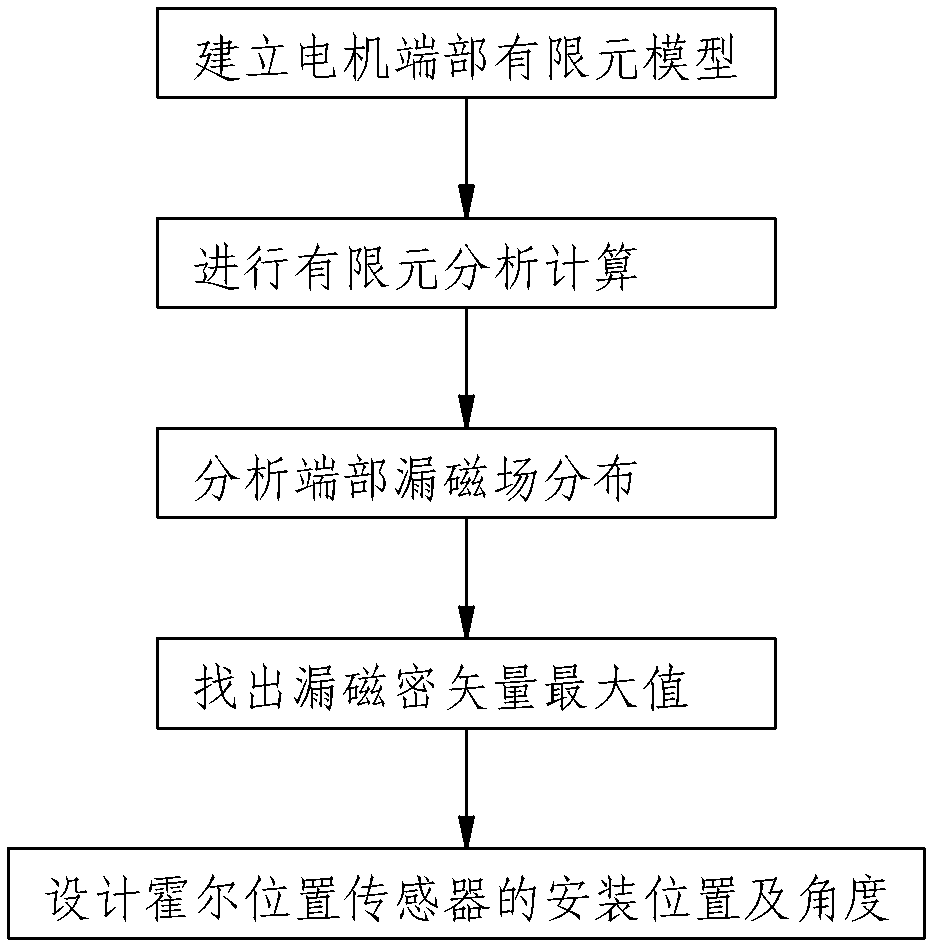

[0029] see Figure 1-Figure 7 , the rotor position detection device of the permanent magnet motor, comprising a Hall position sensor 4 and a permanent magnet 1, a rotor core 2 and a stator core 3 constituting the permanent magnet motor, the permanent magnet 1 is located at the rotor core 2 and the stator core 3 Between the permanent magnet 1 and the rotor core 2, the Hall position sensor 4 is arranged above the upper surface of the permanent magnet 1, and a certain space is reserved between the Hall position sensor 4 and the upper surface of the permanent magnet 1 . The size of this space is determined by the signal strength of the Hall position sensor 4 and the safety distance in actual work.

[0030] In this embodiment, the permanent magnet motor is an outer rotor surface-mounted permanent magnet motor, the stator core 3 is located inside the rotor core 2 , and the permanent magnet 1 is in contact with the inner wall of the rotor core 2 .

[0031] exist Figure 1-Figure 2...

no. 2 example

[0061] see Figure 8-Figure 9 , in this embodiment, the permanent magnet motor is an inner rotor surface mount permanent magnet motor, the rotor core 2 is located inside the stator core 3 , and the permanent magnet 1 is in contact with the outer circumference of the rotor core 2 .

[0062] In fact, the position detection principle of the present invention is mainly aimed at the leakage magnetic field at the end, so there is no obvious distinction for any kind of permanent magnet motor. See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com