Induction cooker wire reel and wire reel winding process

A technology of induction cooker and reel, which is applied in the direction of transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, circuit, etc. It can solve the problems of cost increase, wire clamp skeleton wear, increase production process, etc., and achieve structural Simple and compact, simplifies the production of molds, and avoids the effect of tedious work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

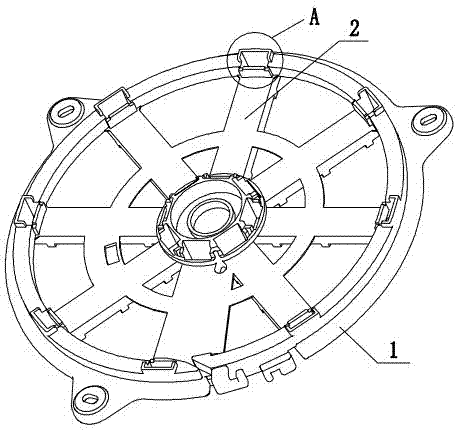

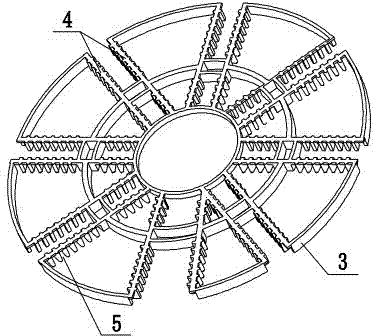

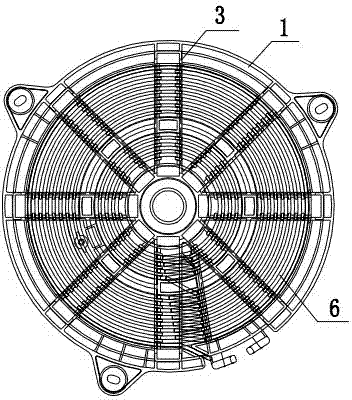

[0025] The wire reel of an induction cooker includes a wire reel base 1, a wire clamping frame 3, and a coil 6 arranged between the wire reel base 1 and the wire clamping frame 3. The coil 6 of the present invention is an aluminum wire; wherein, the wire reel base 1 is a planar structure, This simplifies the mold structure for making the wire reel base. A group of first reinforcing ribs 2 are evenly arranged on the wire reel base 1. The second reinforcing rib 4, on the second reinforcing rib 4, the clamping slots 5 for clamping the coil 6 are arranged at equal intervals, the clamping slot 5 is formed by two adjacent groove teeth, and the gap between the clamping slots 5 matches the diameter of the coil 6 The outer end of the first reinforcing rib 2 of the wire reel base 1 is provided with a boss 7 that matches the outer end structure of the second reinforcing rib 4 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com