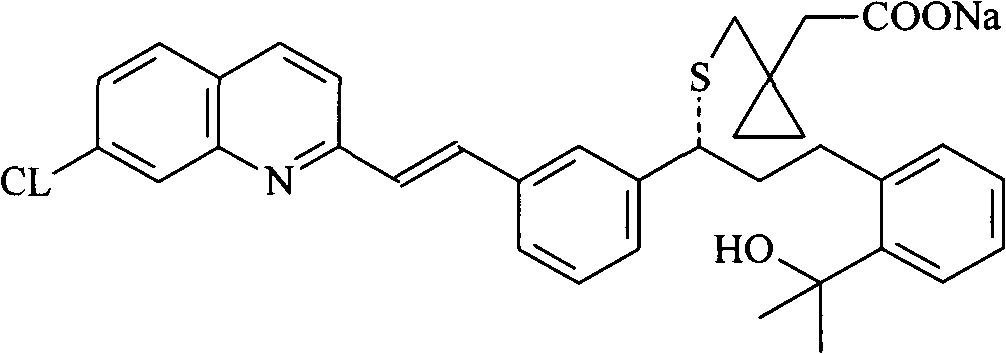

Montelukast sodium composition

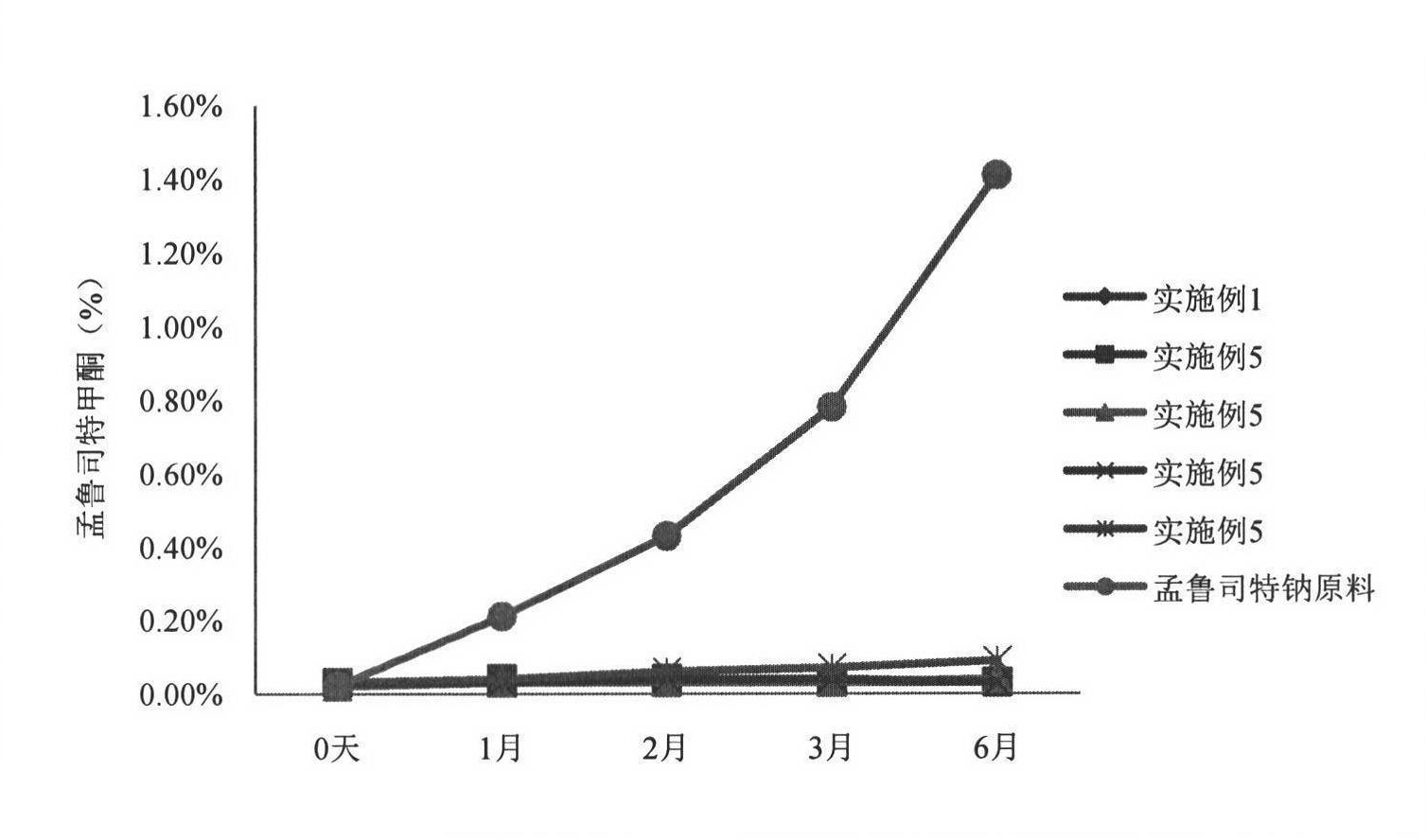

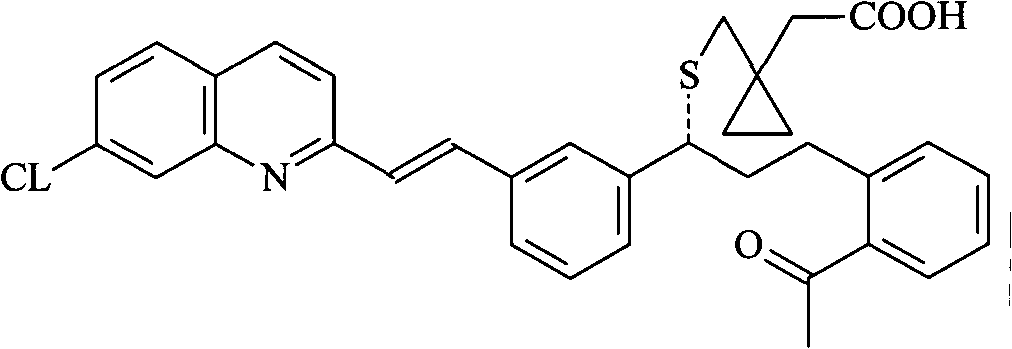

A technology of montelukast sodium and its composition, which is applied in the field of pharmaceutical manufacturing, can solve problems such as no improvement, achieve considerable economic and social benefits, good repeatability, and reduce hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prescription of Montelukast Sodium Granules:

[0023]

[0024] Preparation:

[0025] Mix and pulverize montelukast sodium and polyacrylic acid resin L100-55 through 80 mesh to obtain mixed powder of montelukast sodium polyacrylic acid resin L100-55; Pour alcohol and hypromellose into a wet granulator and mix for 5 minutes, add water to prepare a soft material, granulate with 14 mesh, dry at 60 degrees for 2 hours, granulate with 24 mesh, add the prescribed amount of magnesium stearate and mix for 10 minutes, use Composite film filling, the difference in filling volume is controlled within ±5%.

Embodiment 2

[0027] Montelukast sodium chewable tablet prescription:

[0028]

[0029] Preparation:

[0030] Mix and pulverize montelukast sodium and polyacrylic acid resin L100-55 through 80 meshes to obtain montelukast sodium polyacrylic acid resin L100-55 mixed powder; mix montelukast sodium polyacrylic resin L100-55 mixed powder, micro Pour crystalline cellulose, mannitol, and hypromellose into a wet granulator and mix for 5 minutes, add water to prepare a soft material, granulate at 24 mesh, dry at 60°C for 2 hours, granulate at 20 mesh, add the prescribed amount of magnesium stearate Mix for 10 minutes, compress into tablets, and pack separately.

Embodiment 3

[0032] Prescription of Montelukast Sodium Tablets:

[0033]

[0034] Preparation:

[0035] Mix and pulverize montelukast sodium and polyacrylic acid resin L100-55 through 80 meshes to obtain montelukast sodium polyacrylic acid resin L100-55 mixed powder; mix montelukast sodium polyacrylic resin L100-55 mixed powder, micro Pour crystalline cellulose, lactose, and hypromellose into a wet granulator and mix for 5 minutes, add water to prepare a soft material, granulate at 24 mesh, dry at 60 degrees for 2 hours, granulate at 20 mesh, add the prescribed amount of magnesium stearate Mix for 10 minutes, press into tablets, and pack separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com