Method for manufacturing head of iron golf stick

A manufacturing method and golf technology, applied to golf balls, golf clubs, manufacturing tools, etc., can solve problems such as poor joint stability, achieve easy adjustment of inclination angle, enhance hitting function, and increase hitting distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

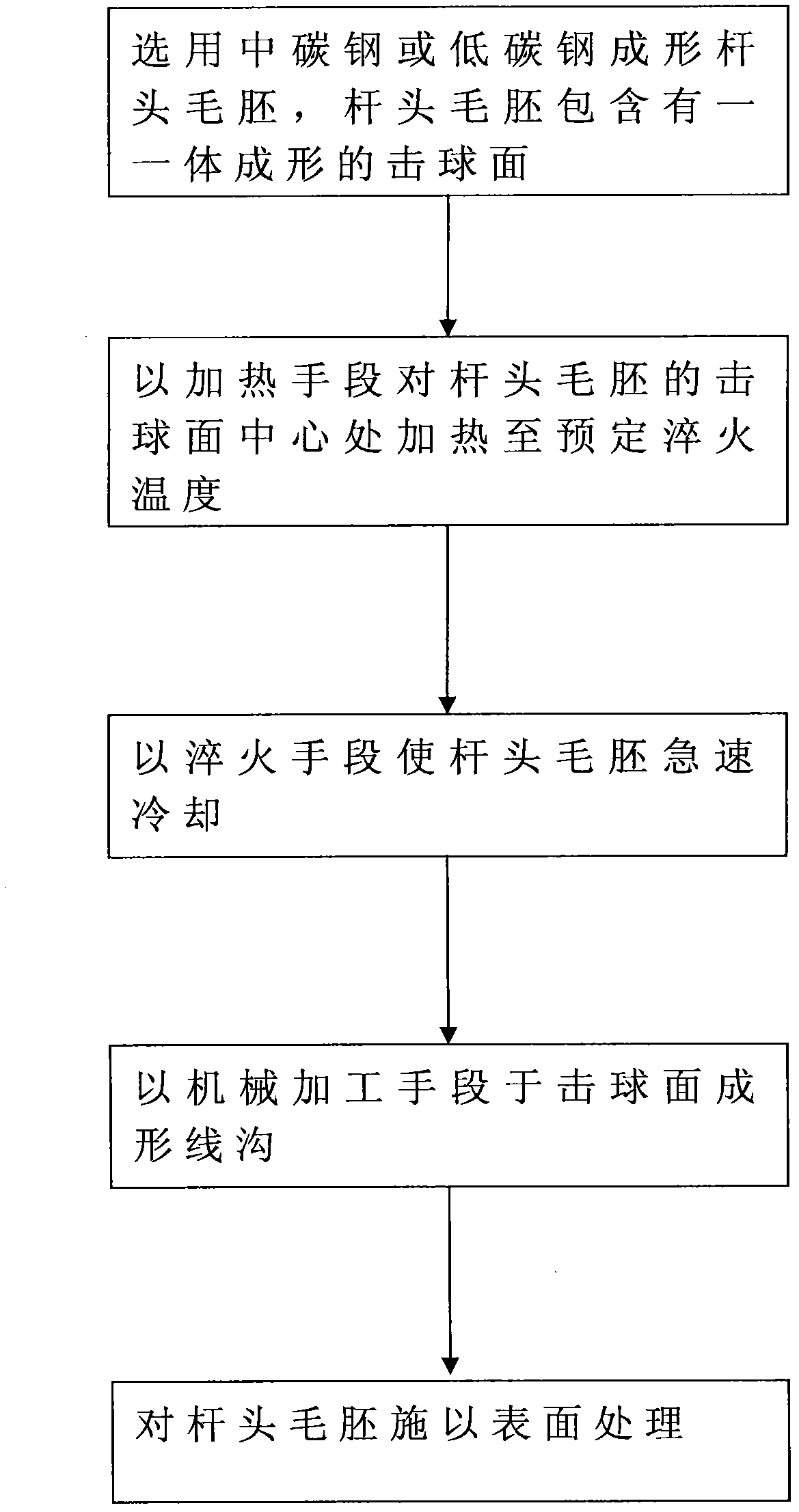

[0030] Such as figure 1 As shown, the specific implementation steps of the golf iron club head manufacturing method of the present invention include:

[0031] Use materials such as medium carbon steel (0.25-0.60% carbon content) or low carbon steel (below 0.25 carbon content) to form iron club head blanks, in which medium carbon steel can be made by precision casting or forging. or low-carbon steel and other materials to form a club head blank, and the club head blank includes an integrally formed ball striking surface;

[0032] Heating the center of the ball striking face of the club head blank to the predetermined quenching temperature by means of heating, wherein the heating means can be selected from flame heating, medium frequency / high frequency induction he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com