Modified palladium-carbon catalyst for producing chloroacetic acid and preparation method for catalyst

A technology of palladium carbon catalyst and chloroacetic acid, which is applied in the preparation of carboxylate, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems that affect the effective promotion of catalysts, short catalyst life, high reaction temperature, etc., and achieve improved removal Effect, high product quality, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

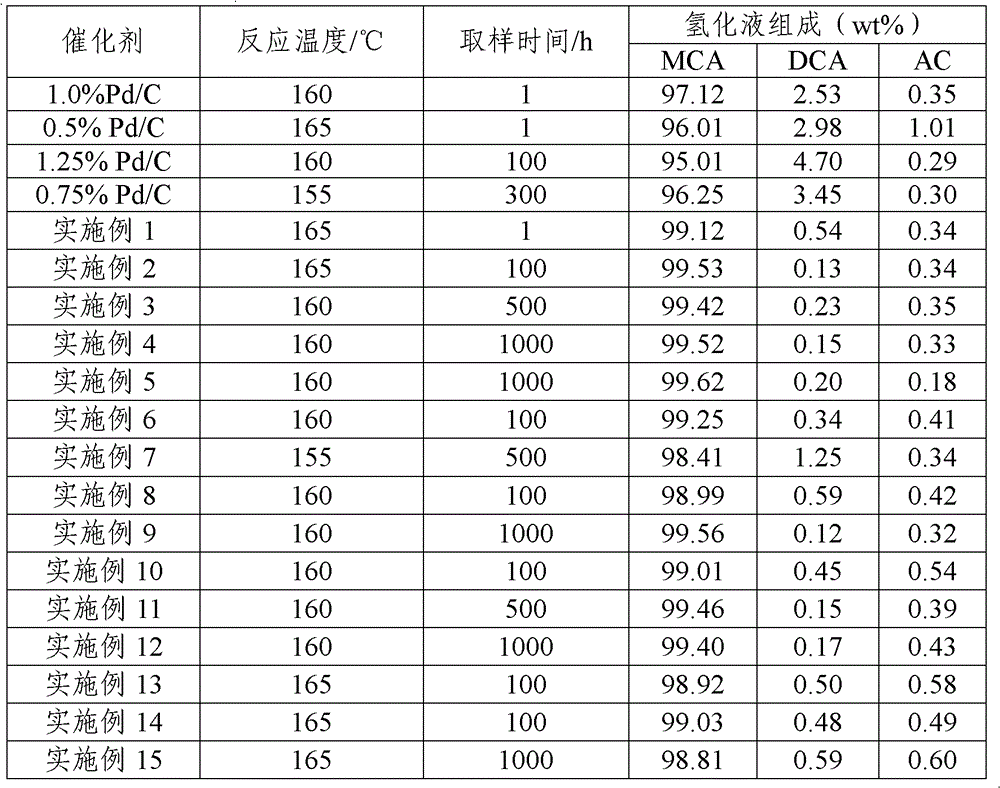

Examples

Embodiment 1

[0028] The modified palladium carbon catalyst for the production of chloroacetic acid of the present embodiment is composed of the following components in mass percentage: 0.5% active component, 0.05% metal additive, and the balance is a carrier; the active component is metal palladium, and the The metal additive is metal barium, and the carrier is columnar activated carbon.

[0029] The preparation method of the modified palladium carbon catalyst of the present embodiment is:

[0030] Step 1, the columnar activated carbon is mixed with HNO with a mass concentration of 10% under the condition of a temperature of 70°C 3 Heat to reflux for 2h, then wash the columnar activated carbon after heating to reflux to neutrality;

[0031] Step 2. Add the washed columnar activated carbon in the step 1 into the aqueous solution of barium nitrate, place it in a boiling water bath after impregnating equal volumes at normal temperature to evaporate the moisture, then place it in an oven for ...

Embodiment 2

[0034] The modified palladium-carbon catalyst for the production of chloroacetic acid of the present embodiment is composed of the following components by mass percentage: 1.25% of the active component, 1% of the metal additive, and the balance is a carrier; the active component is metal palladium, and the The metal additive is metal barium, and the carrier is columnar activated carbon.

[0035] The preparation method of the modified palladium carbon catalyst of the present embodiment is:

[0036] Step 1, the columnar activated carbon is mixed with HNO with a mass concentration of 2% at a temperature of 100°C 3 Heating to reflux for 6h, then washing the columnar activated carbon after heating to reflux to neutrality;

[0037] Step 2. Add the washed columnar activated carbon in the step 1 into the aqueous solution of barium nitrate, place it in a boiling water bath after impregnating it in an equal volume at normal temperature, evaporate the water to dryness, then place it in ...

Embodiment 3

[0040] The modified palladium-carbon catalyst for the production of chloroacetic acid of the present embodiment is composed of the following components in mass percentage: 0.7% of the active component, 0.1% of the metal additive, and the balance is a carrier; the active component is metal palladium, and the The metal additive is metal barium, and the carrier is columnar activated carbon.

[0041] The preparation method of the modified palladium carbon catalyst of the present embodiment is:

[0042] Step 1, the columnar activated carbon is mixed with HNO with a mass concentration of 5% under the condition of a temperature of 90°C 3 Heat to reflux for 4h, then wash the columnar activated carbon after heating to reflux to neutrality;

[0043] Step 2. Add the washed columnar activated carbon in the step 1 into the aqueous solution of barium nitrate, place it in a boiling water bath after impregnating equal volumes at normal temperature to evaporate the moisture, then place it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com