Vacuum worktable capable of heating and accurately positioning

A precise positioning and vacuum suction technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of unevenness, limitation, low cost, etc., achieve good thermal conductivity, small thermal expansion coefficient, and avoid impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

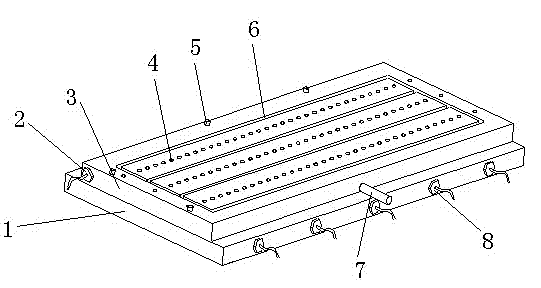

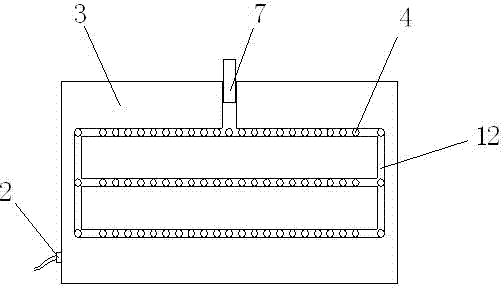

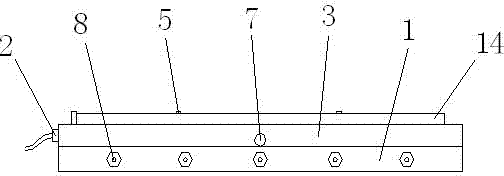

[0012] Such as Figure 1 to Figure 4 As shown, the heating and precise positioning vacuum suction workbench consists of a workbench body 10 with a suction hole 4, a heating rod 8, a temperature sensor 2 and a heating controller 9, a connecting hose 7, a solenoid valve 13 and a negative pressure generator 11 compositions. The vacuum table body 10 has a two-layer structure, the upper layer is a vacuum layer 3, the surface has positioning pins 5 for workpiece positioning and grooves 6 compatible with the convex part of the workpiece 14, and a number of suction holes are arranged on the vacuum layer 3 4. The bottom surface is provided with a number of interconnected gas circuits 12 perpendicular to and connected to the suction hole 4; the lower layer is a heating layer 1, which is slightly larger than the upper layer, and the extra area is used for fixing and heating the vacuum table body 10. Layer 1 is provided with heating rods 8 and a temperature sensor 2 . Such as Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com