Forging method for improving horizontal mechanical property of flat and square forging piece

A technology of transverse mechanical properties and forgings, which is applied in the field of free forging, can solve the problems of insufficient consideration of transverse properties, low transverse properties, unqualified transverse properties of forgings, etc., and achieve the effect of improving transverse mechanical properties and reducing anisotropic difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

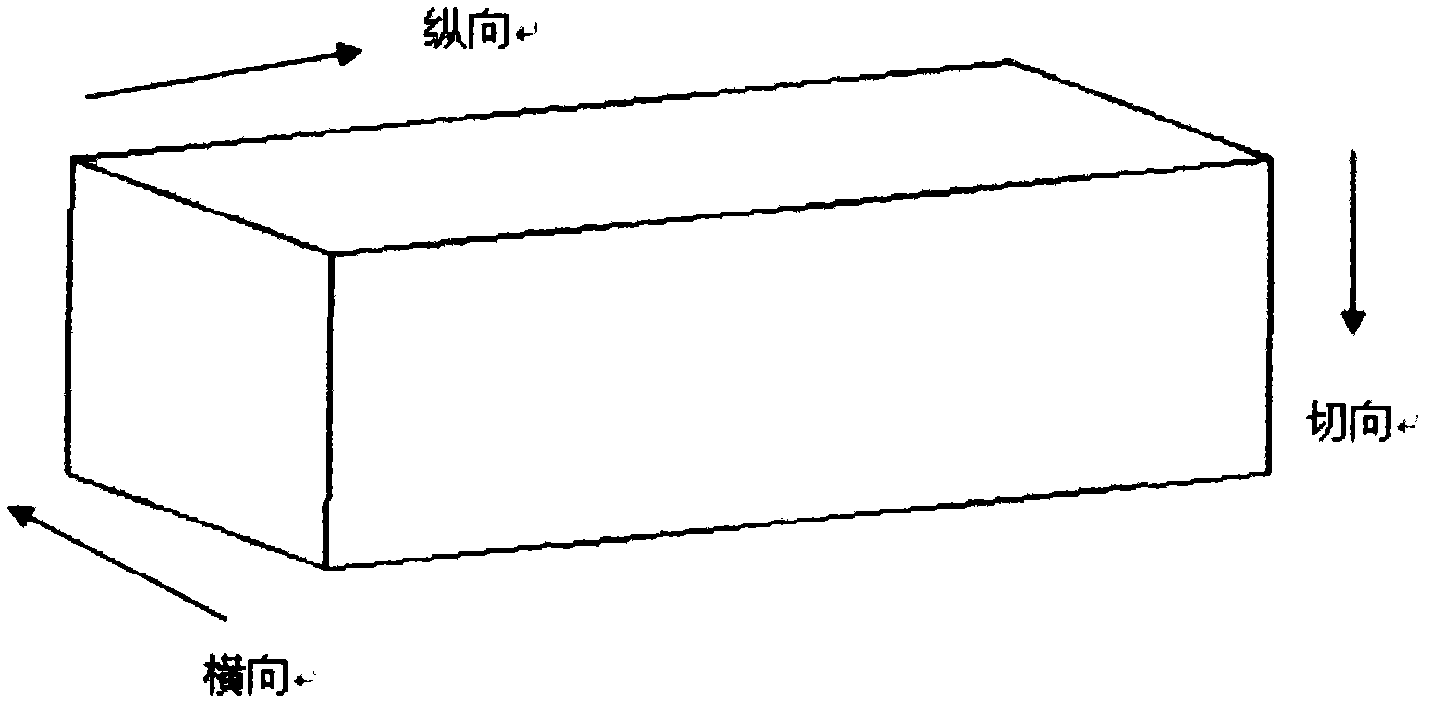

[0023] Firstly, the steel ingot WHF method is used for upsetting and drawing to ensure that the core of the steel ingot is fully forged; after drawing, the square is 1400×700×440, that is, the longitudinal length is 1400mm, the transverse length is 700mm, and the tangential length is 440mm. It is consistent with the axis of the steel ingot, that is, the metal flow direction is consistent with the transverse direction of the forging, which improves the transverse performance of the forging; secondly, upsetting along the length direction of 1400mm to H=910mm, and the deformation is controlled at about 35%; flattening along the direction of 910mm to the finished product The size can improve the obvious fiber directionality caused by the main deformation, improve the transverse tangential performance and at the same time improve the performance directionality; 4) heat treatment for forgings; 5) take test bars in transverse direction of forgings for inspection. After the transverse ...

Embodiment 2

[0025] Firstly, the steel ingot WHF method is used for upsetting and drawing to ensure that the core of the steel ingot is fully forged; after drawing, the square is 1400×700×440, that is, the longitudinal length is 1400mm, the transverse length is 700mm, and the tangential length is 440mm. It is consistent with the axis of the steel ingot, that is, the metal flow direction is consistent with the transverse direction of the forging, which improves the transverse performance of the forging; secondly, upsetting along the length direction of 1400mm to H=980mm, and the deformation is controlled at about 30%; flattening along the direction of 980mm to the finished product The size can improve the obvious fiber directionality caused by the main deformation, improve the transverse tangential performance and at the same time improve the performance directionality; 4) heat treatment for forgings; 5) take test bars in transverse direction of forgings for inspection. After the transverse ...

Embodiment 3

[0027] Firstly, the steel ingot WHF method is used for upsetting and drawing to ensure that the core of the steel ingot is fully forged; after drawing, the square is 1400×700×440, that is, the longitudinal length is 1400mm, the transverse length is 700mm, and the tangential length is 440mm. It is consistent with the axis of the steel ingot, that is, the metal flow direction is consistent with the transverse direction of the forging, which improves the transverse performance of the forging; secondly, upsetting along the length direction of 1400mm to H=840mm, and the deformation is controlled at about 40%; flattening along the direction of 840mm to the finished product The size can improve the obvious fiber directionality caused by the main deformation, improve the transverse tangential performance and at the same time improve the performance directionality; 4) heat treatment for forgings; 5) take test bars in transverse direction of forgings for inspection. After the transverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com