Pre-upset one-heating forming mold and pre-upset process

A technology of forming molds and firing times, which is applied in the direction of manufacturing tools, metal processing equipment, transportation and packaging, etc., can solve problems such as folding, and achieve the effects of reducing production costs, improving production efficiency, and reducing cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with specific embodiments;

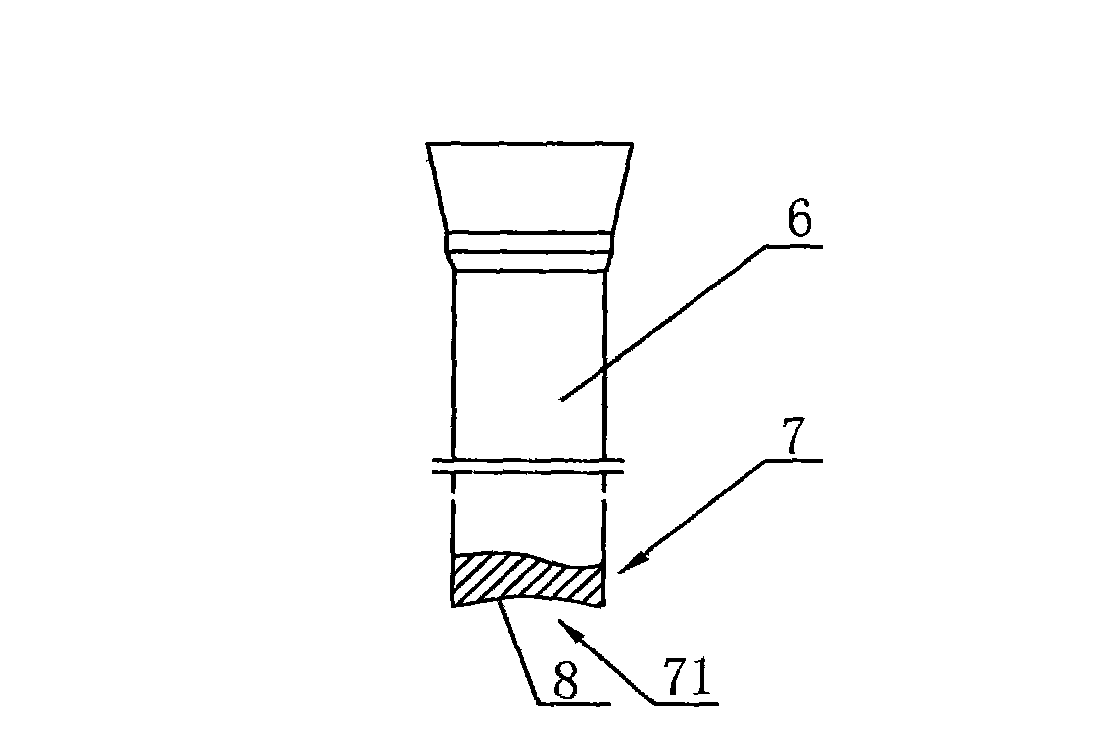

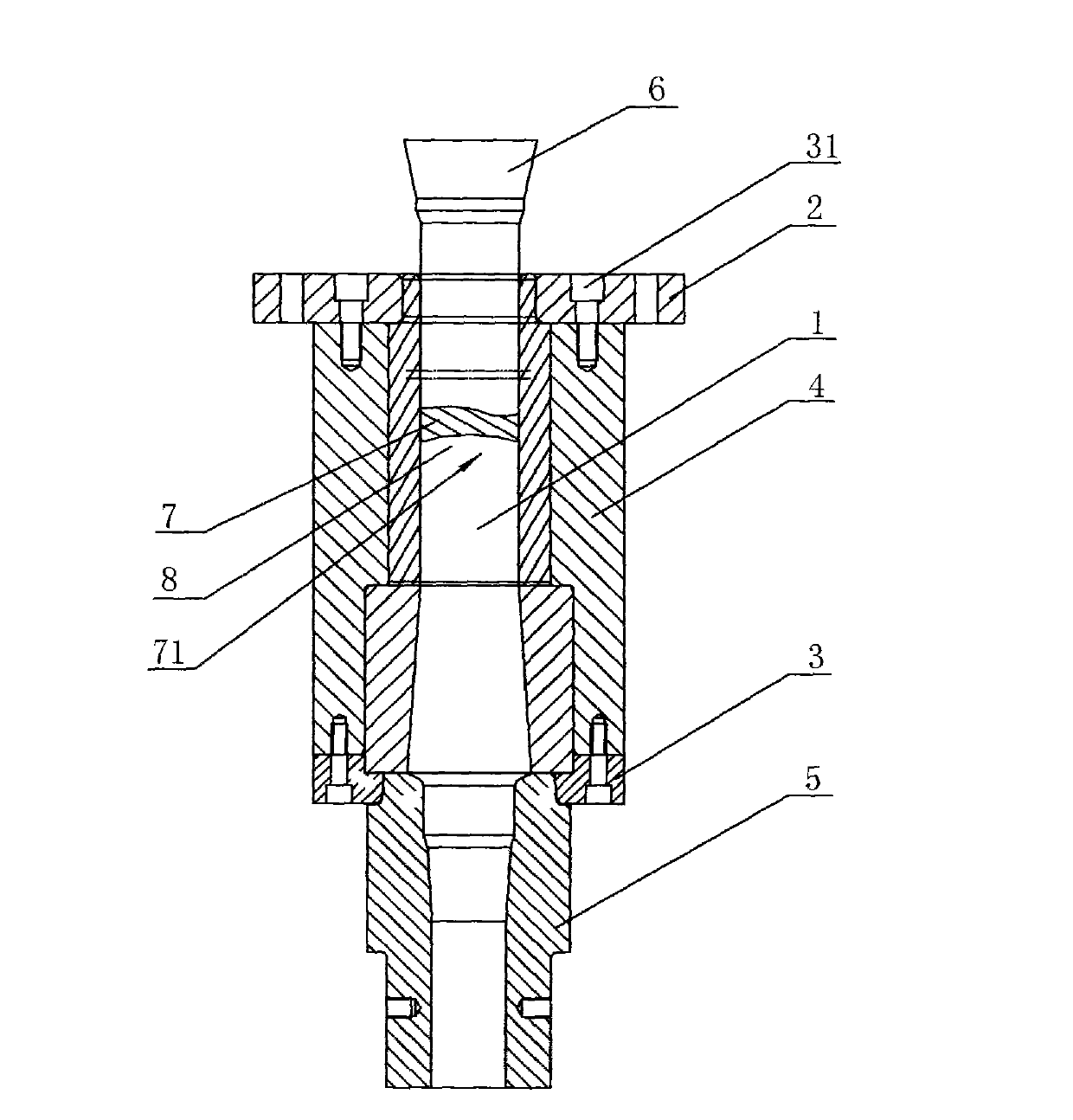

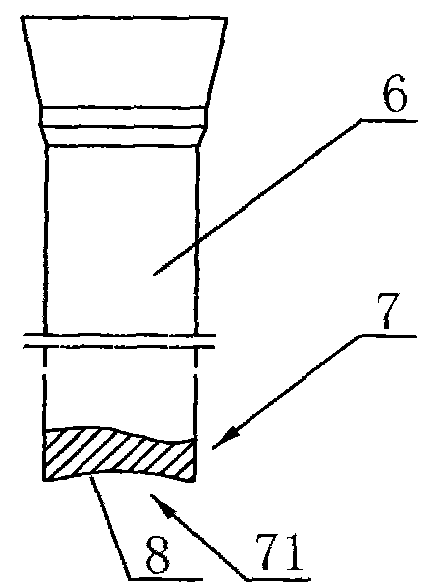

[0017] Such as figure 1 , 2 As shown, a pre-upsetting one-fire forming mold is composed of an upper mold flange 2, a lower mold flange 3, an upper mold plate 4, a lower mold plate 5, and a pressure rod 6 with an indenter 7. The upper mold flange 3 is fixed to the top of the upper mold plate 4 by screws 31, the upper mold plate 4 and the lower mold plate 5 are fixedly connected by the lower mold flange plate 3 provided at the bottom of the upper mold plate 4, and the pressure rod 6 is set in the stamping In the cavity 1; on the pressing surface 71 of the pressing head 7 is provided an inner recess 8 recessed to the inside of the pressing head 7, and the extension of the inner recess 8 along the pressing surface 71 is smaller than the diameter of the pressing surface. The shape of the inner concave portion is set to be arc, square or rectangular in longitudinal section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com