Method for low-pressure casting of aluminium alloy patterned ring by using low-pressure casting mould

A low-pressure casting and pattern ring technology, applied in the field of low-pressure casting, can solve problems such as long cooling time, shrinkage porosity, and large heat capacity, and achieve the effects of ensuring dimensional accuracy, improving work efficiency, and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

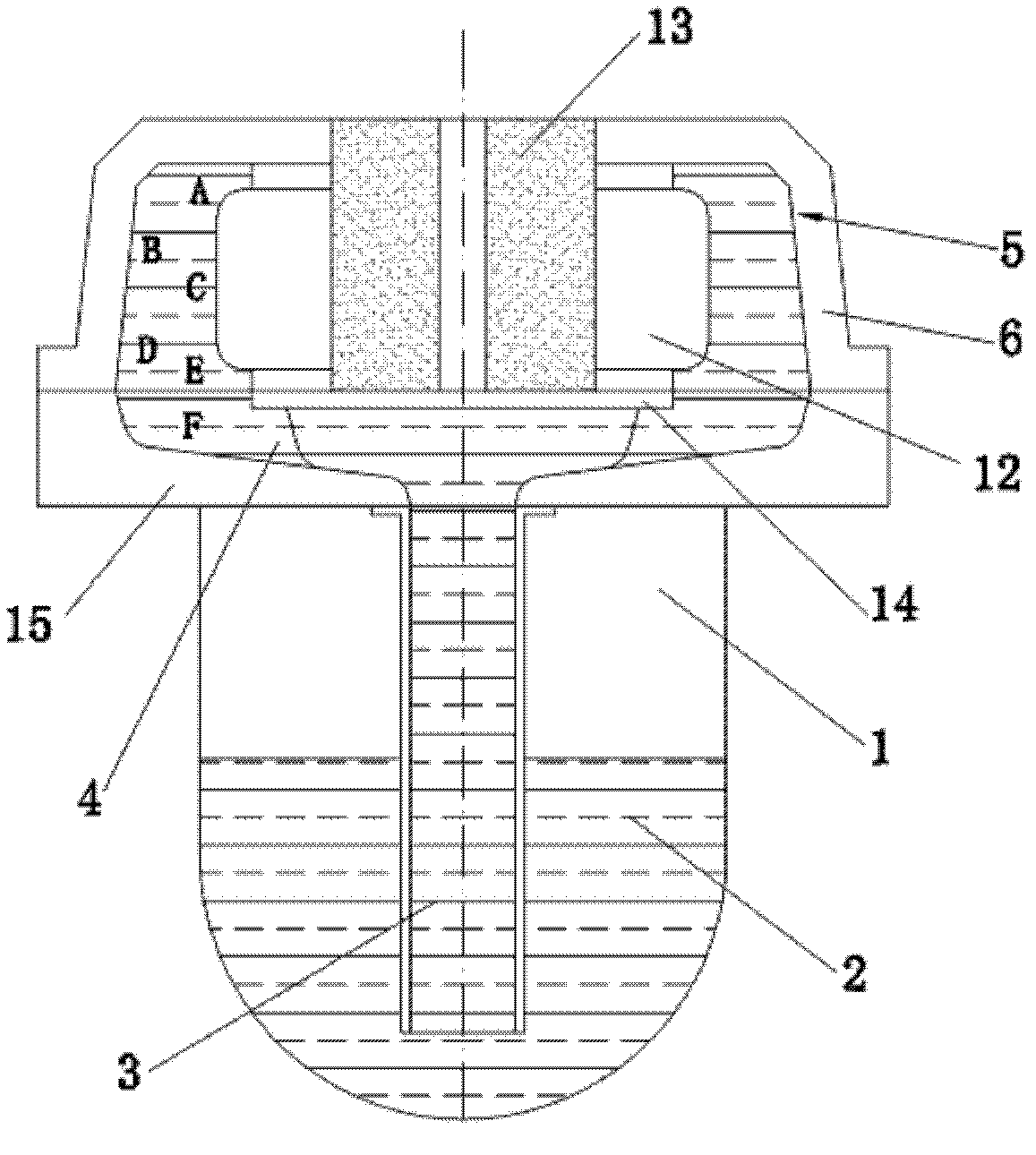

[0037] Embodiment 1: refer to Figure 3-5 , the outer mold 6 of the present invention is low-pressure casting of aluminum alloy pattern rings, and a cooling liquid flow channel 7 that surrounds the outer mold body in a circumferential direction is arranged in its body, and the distance between its center and the bottom surface of the outer mold is 1 / 4 of the height of the outer mold , and a partition plate 8 is arranged in the cooling liquid flow channel, and a water inlet nozzle 9 and a water outlet nozzle 10 of the cooling liquid flow channel are respectively arranged on both sides of the partition plate.

[0038] A sealing plate 11 is provided on the outside of the cooling liquid channel 7 to seal the cooling liquid channel, and the outer wall of the sealing plate 11 is on the same plane as the outer wall of the outer mold body. In the specific setting, the cross-sectional area of the coolant channel 7 is 15cm 2 , the wall thickness of the outer mold body on its inner si...

Embodiment 2

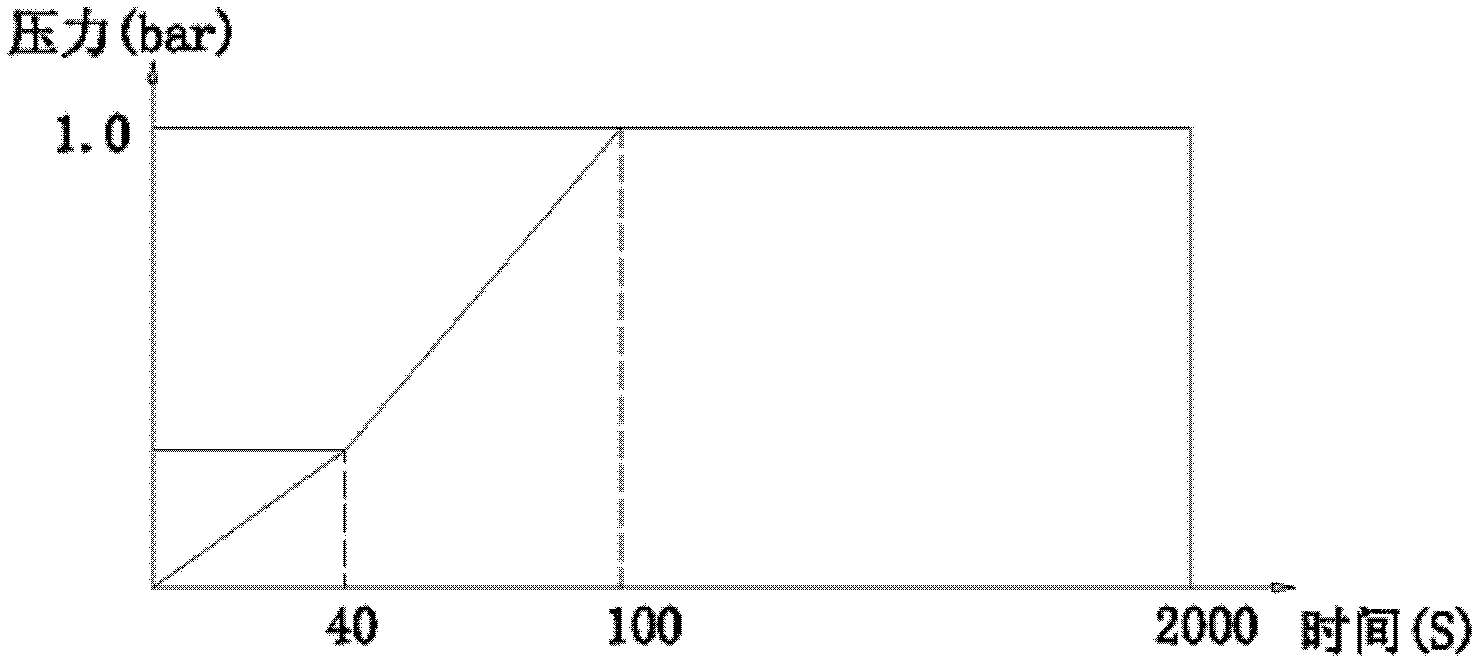

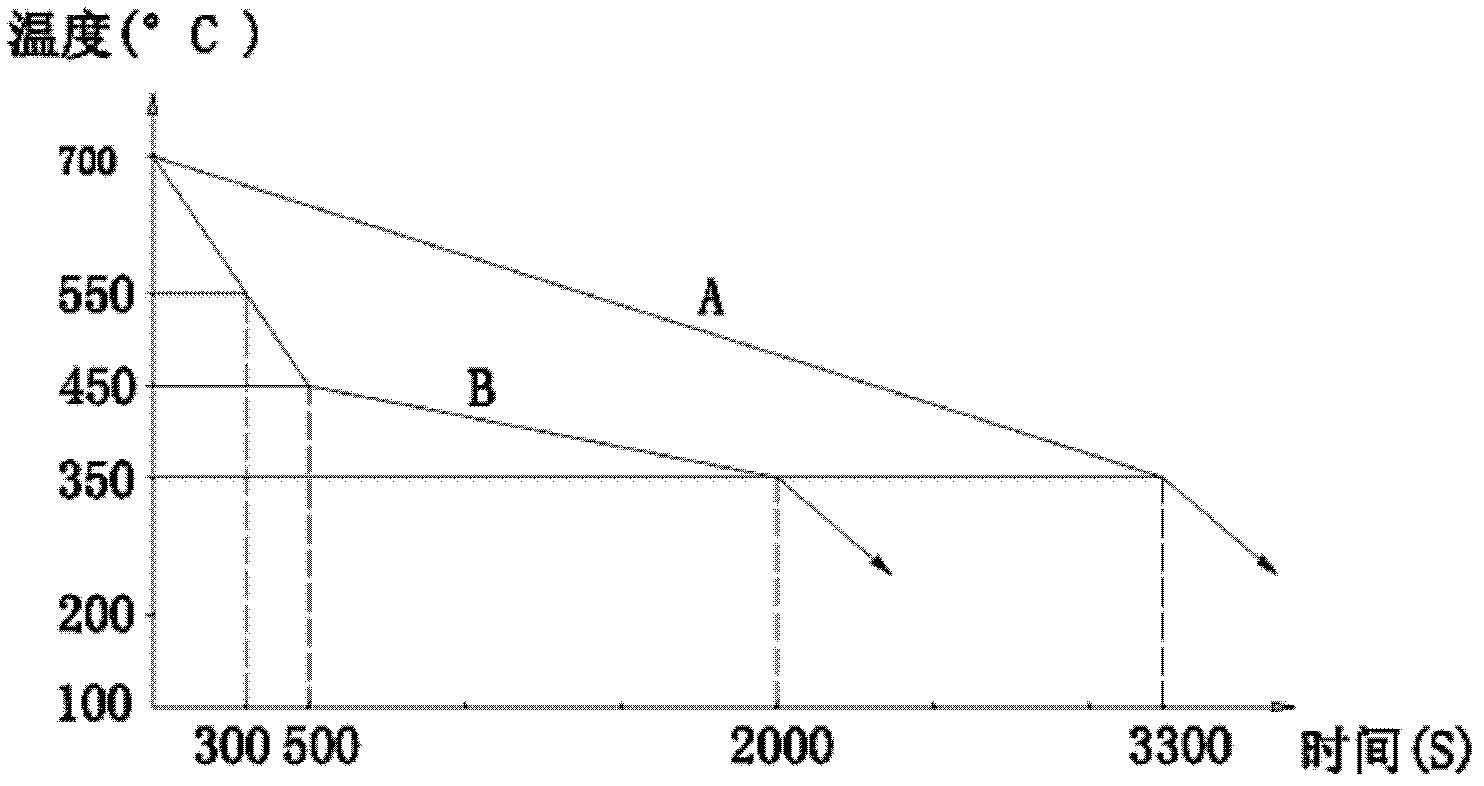

[0039] Example 2: In this example, the casting process parameters are set according to the following conditions: the outer mold is preheated at 350°C, the plaster core is preheated at 110°C, the runner is preheated at 400°C, and the pouring temperature is 700°C. Filling process according to figure 1 The pressure curve shown is carried out, the filling pressure is 0.3bar, the filling speed is 0.007bar / s, the holding pressure is 1.0bar, and the time is 2000s. During this process, 50-60s after the aluminum liquid is full, start to fill the outer mold with cooling water, and control the flow rate to 150-200cm 3 / min lasts for 500-600s and then stops. After the pressure holding time reaches 2000s, when the temperature of the casting drops to 350°C, the pressure is released, the mold is demoulded, and the cooling is continued at room temperature. The control of the flow rate is based on the size of the casting wall thickness 80-100mm, at 150-200cm 3 Select within the range of / s....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com