Aluminum alloy brazing sheet and manufacturing method thereof as well radiator part

A manufacturing method and technology of aluminum alloy, applied in the direction of heat exchange equipment, lighting and heating equipment, etc., can solve the problem of high cost of continuous annealing production line, and achieve the effect of good forming performance, brazing performance and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

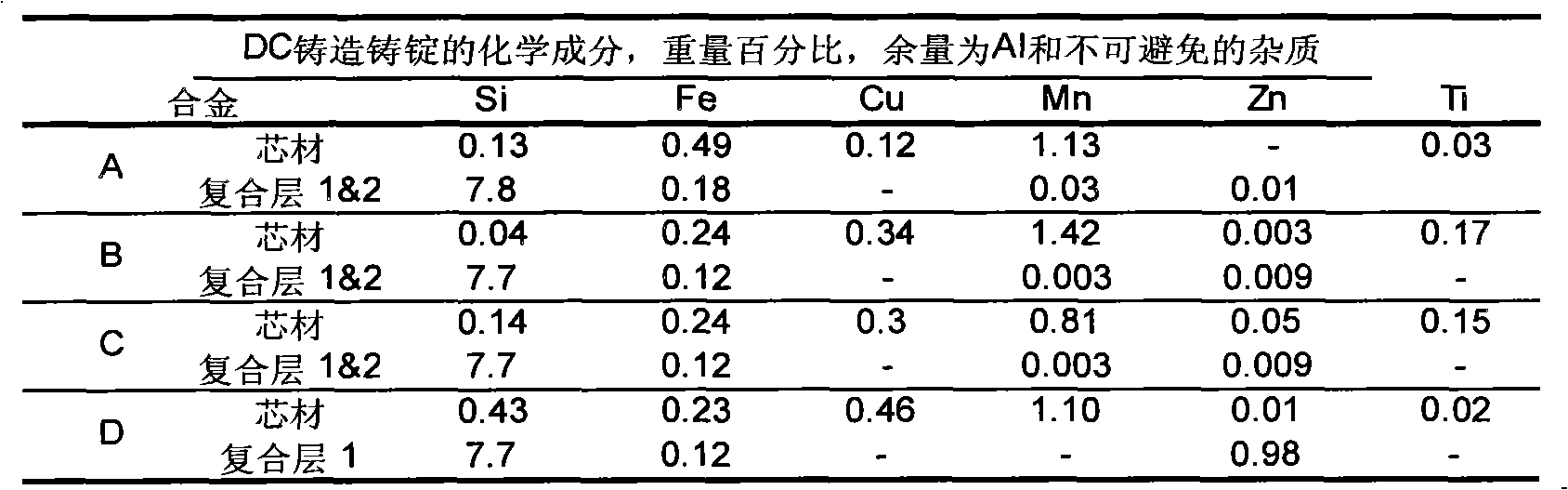

[0021] The invention provides an AA3XXX aluminum-manganese series aluminum alloy brazing sheet material with good formability and brazing performance and a manufacturing method thereof. This sheet can be used for radiator components such as evaporators, main boards, side panels, intercoolers and oil coolers.

[0022] The manufacturing method of aluminum alloy brazing sheet material according to the present invention comprises the following steps that are carried out in sequence:

[0023] a) cast aluminum alloy ingot;

[0024] b) Homogenize the ingot, then cool and perform conventional face milling;

[0025] c) performing a single-sided or double-sided composite aluminum-silicon solder layer on the ingot to form a composite material;

[0026] d) heating the compound;

[0027] e) hot rolling and cold rolling the heated composite material to form a cold rolled material having a first thickness;

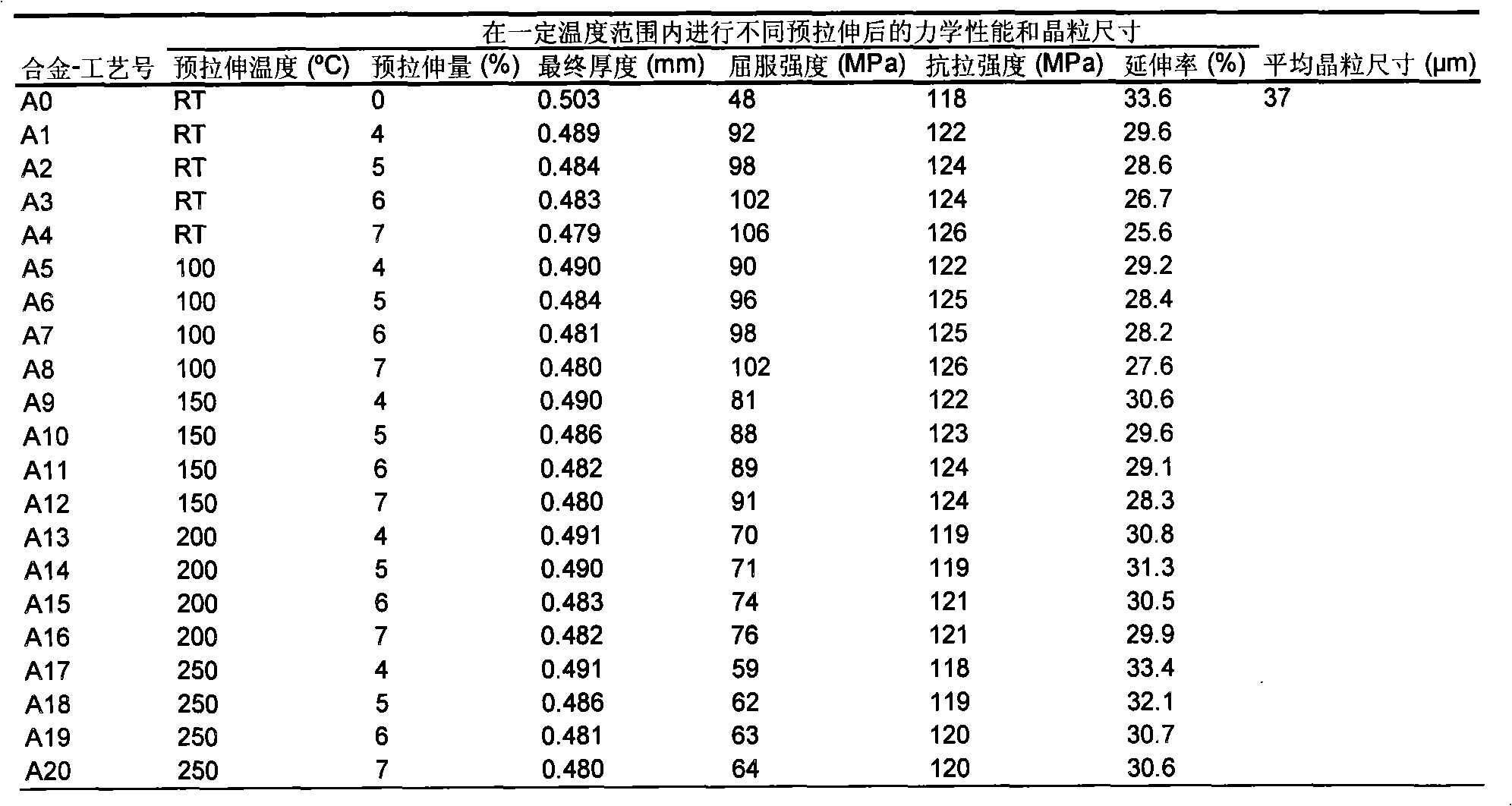

[0028] f) performing complete softening annealing on the cold-rolled material; a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com