Adaptive corner wrapping control device for body paper and control method

A technology of a control device and a control method, applied in the field of corrugated paper processing, can solve the problems of low efficiency, poor adjustment effect, and inability to adjust the production line in real time, and achieve the effect of ensuring adjustment and self-adaptive adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

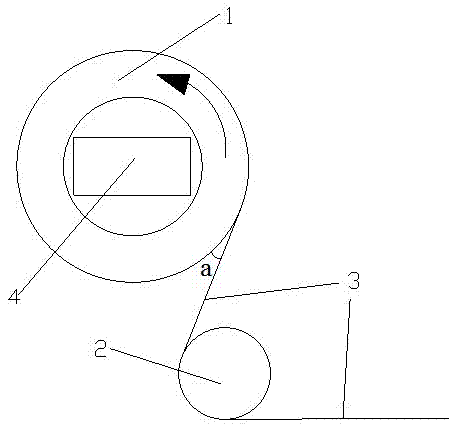

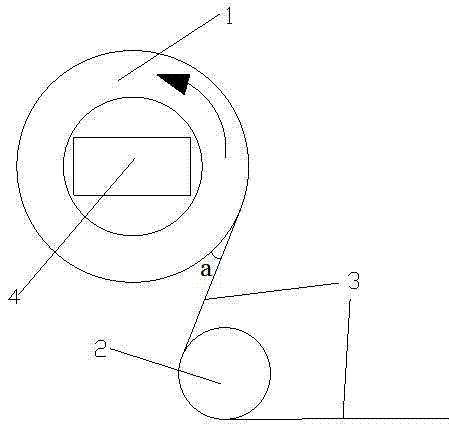

[0022] An adaptive base paper wrap angle control device, such as figure 1 As shown, it includes a controller 5. The controller is specifically a programmable controller-TMS320F2812, a heating cylinder 1 and a cam 2 for transferring the base paper 3 to the heating cylinder 1. The heating cylinder 1 drives the base paper 3 to move, thereby continuously The base paper 3 delivered is heated. The cam 2 is driven by a motor 6, and the position of the cam is adjusted by the motor. The heating cylinder 1 is provided with an encoder 4 for measuring the speed of the base paper 3, and the encoder 4 is connected to the controller 5.

[0023] The encoder 4 is a photoelectric encoder HEDM-5505, which is located at the axis of the heating cylinder 1.

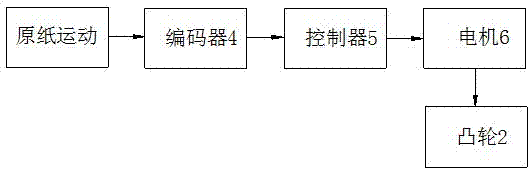

[0024] The control method of the above-mentioned self-adaptive base paper wrap angle control device, such as figure 2 shown, including the following steps:

[0025] Step 1. Establishing a database: In the early stage of debugging, keep the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com