Flat pen automatic assembly line

An assembly line and automatic technology, applied in the repair of ink pens, printing, writing utensils, etc., can solve the problems of wasting manpower, affecting assembly efficiency, and high labor intensity, so as to avoid improper pressing, avoid pen head breakage, and save money. The effect of assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

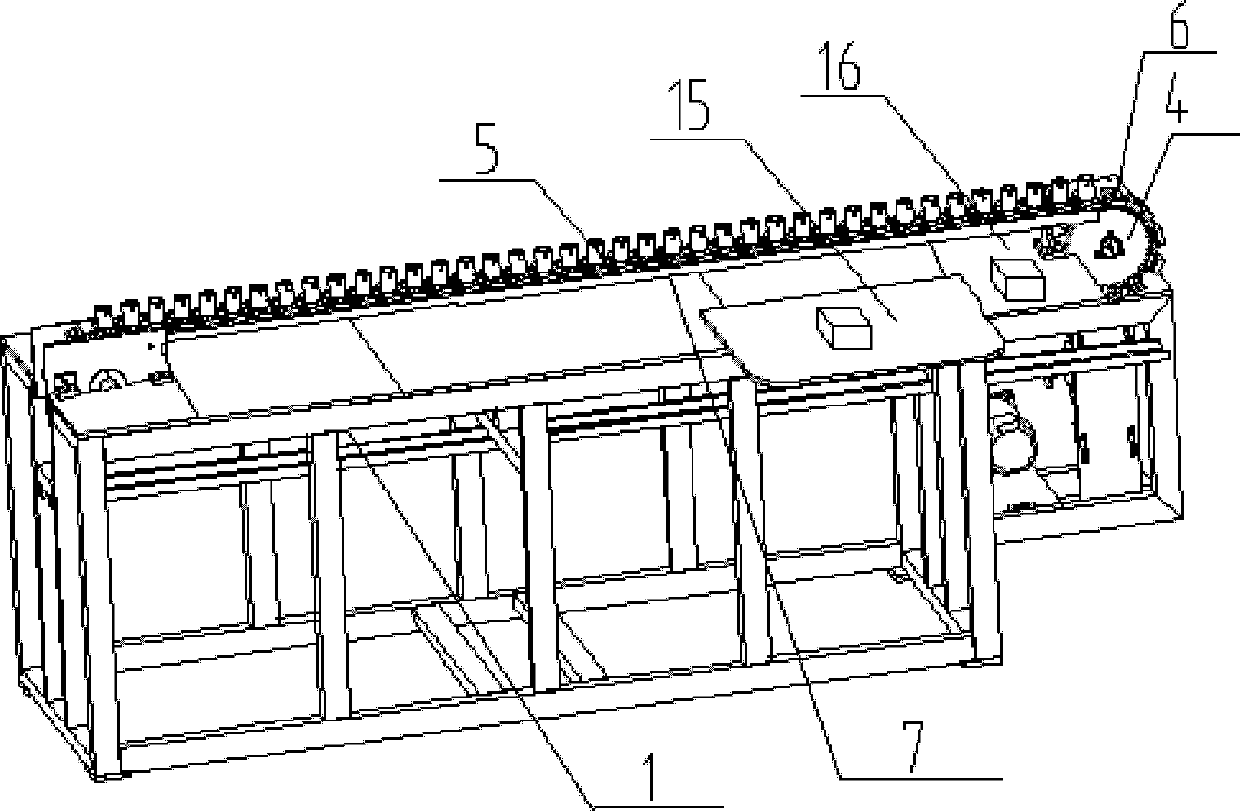

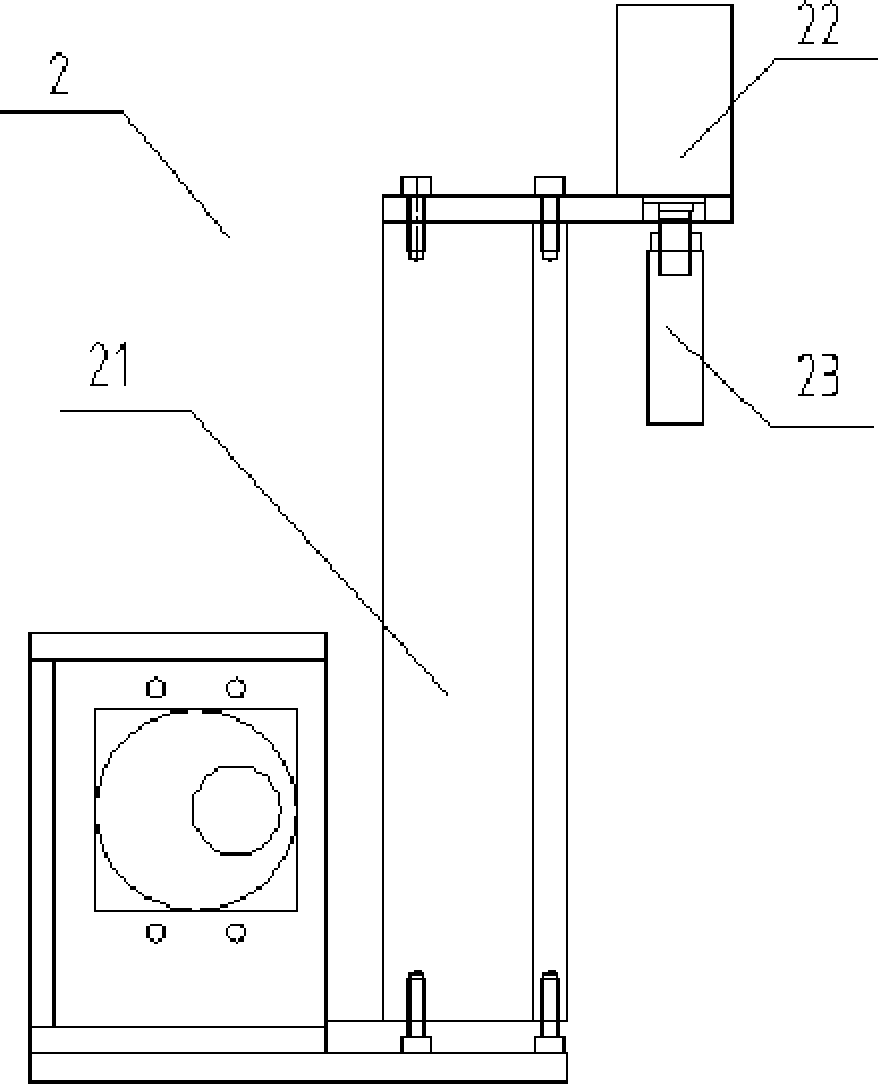

[0021] Embodiment one: if figure 1 As shown, a flat pen automatic assembly line includes a workbench 1, two transmission sprockets 4 and an annular transmission chain 5 connecting the two transmission sprockets 4, and the two transmission sprockets 4 are installed on two sides of the workbench 1 respectively. At the end, the transmission chain 5 is sequentially provided with a plurality of clamps 6 for inserting flat pen holders, and a transmission track 7 supporting the transmission chain 5 is arranged between the two transmission sprockets 4, and the transmission track 7 is fixed on the workbench 1 , The workbench 1 is successively provided with a pen cap loading station 15 and a pen cap pressing station 16, and the pen cap pressing station 16 is provided with an automatic pen cap pressing machine 2. Such as figure 2 As shown, the automatic pen cap pressing machine 2 includes a first bracket 22 , a first cylinder 21 and a pressure rod 23 , the first cylinder 21 is fixed on...

Embodiment 2

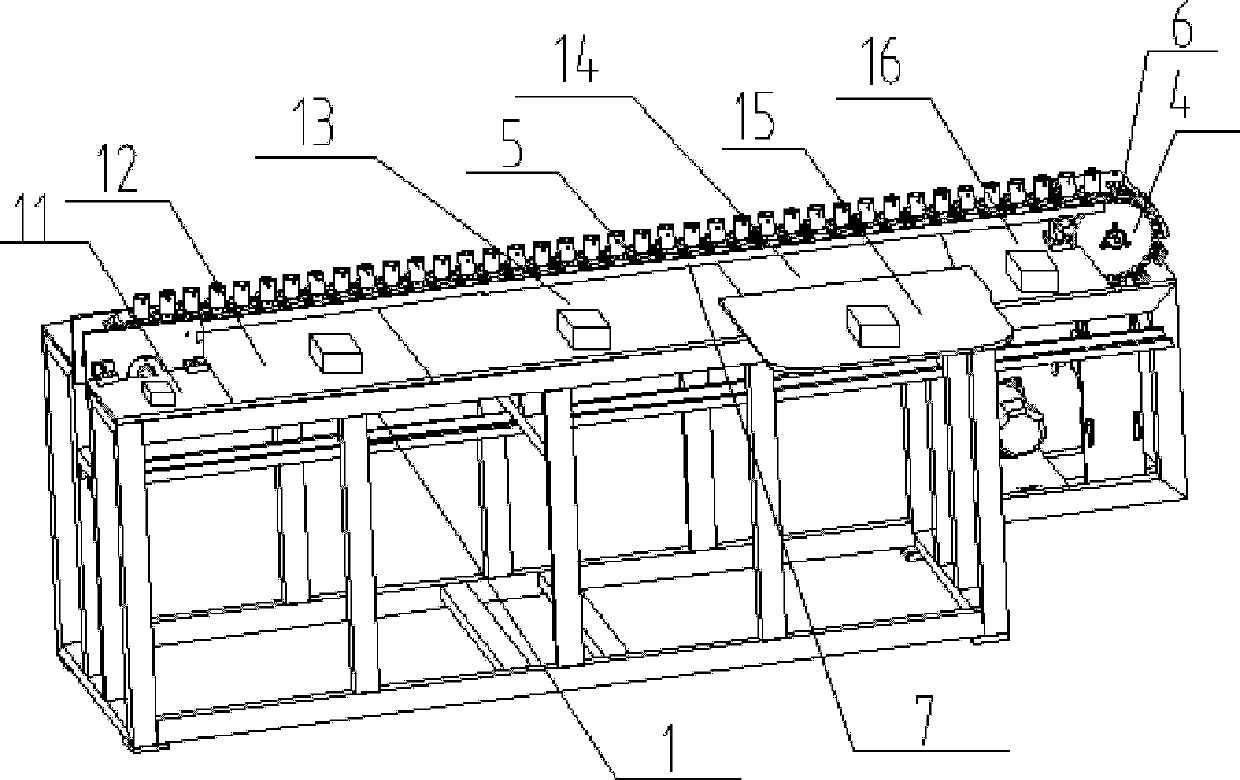

[0023] Embodiment two: if image 3 As shown, the present embodiment is basically the same as Embodiment 1, the difference is that before the pen cap station 15, a feeding station 11, an ink filling station 12, a nib station 13 and a nib station 14 are arranged successively. The station 11 is provided with an automatic feeder, the ink filling station 12 is provided with an automatic ink filling machine, and the nib pressing station 14 is provided with an automatic nib pressing machine 3, such as Figure 4 As shown, the automatic nib press machine 3 includes a second support 32, a second cylinder 31 and a pressing mold 33, the second cylinder 32 is fixed on the second support 33, and one end of the pressing mold 33 is fixed on the cylinder shaft of the second air cylinder 32 , the other end of pressing mold 33 is provided with the groove 331 that matches with nib, and the working principle of automatic nib pressing machine 3 is: when the flat pen semi-finished product that nib i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com