Pneumatic run flat tire

A pneumatic tire and run-flat technology, which is applied to special tires, tire parts, tire tread/tread pattern, etc., can solve the problems of insufficient ride comfort effect, improve ride comfort, maintain lack of Durability for air retention and damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

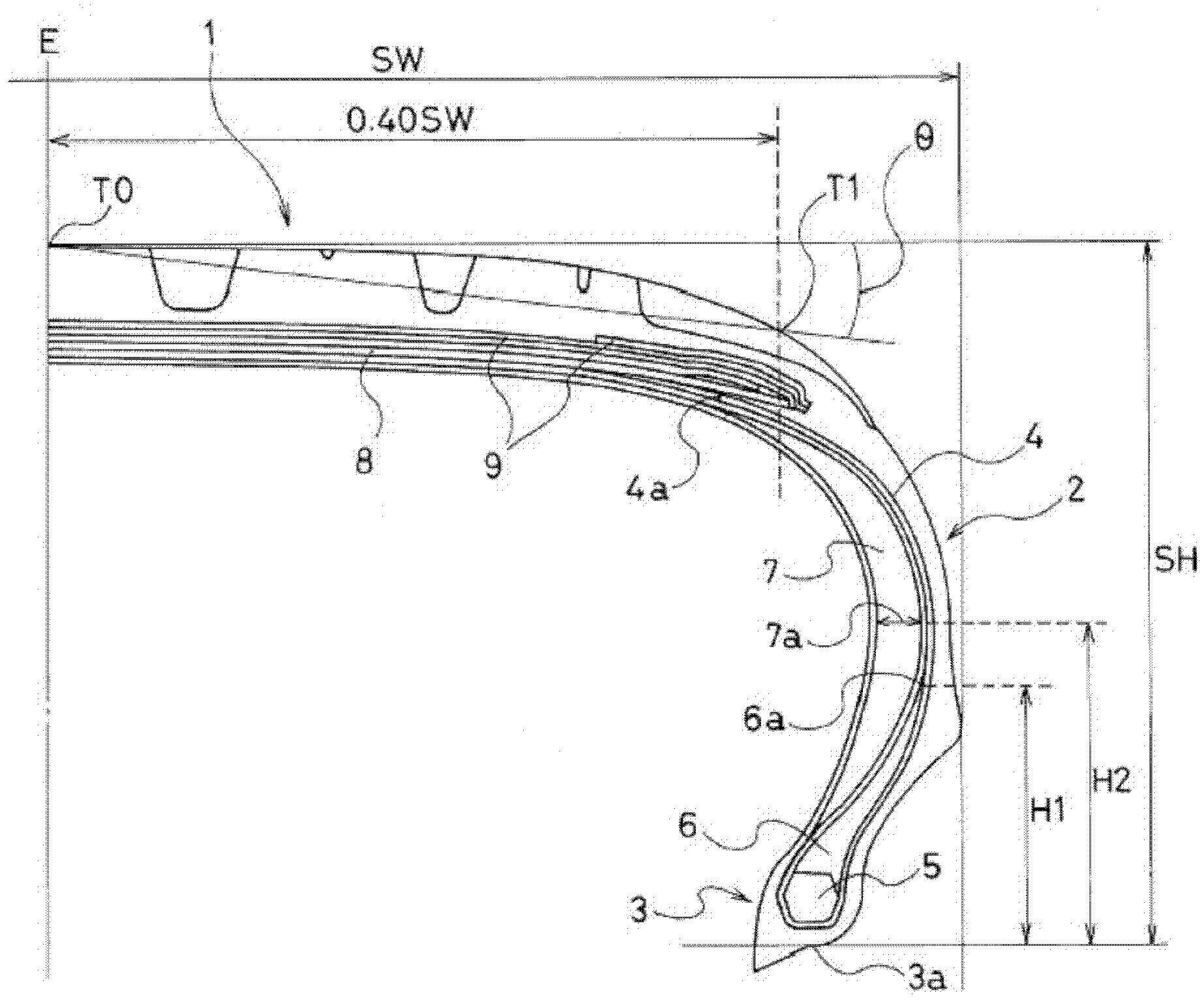

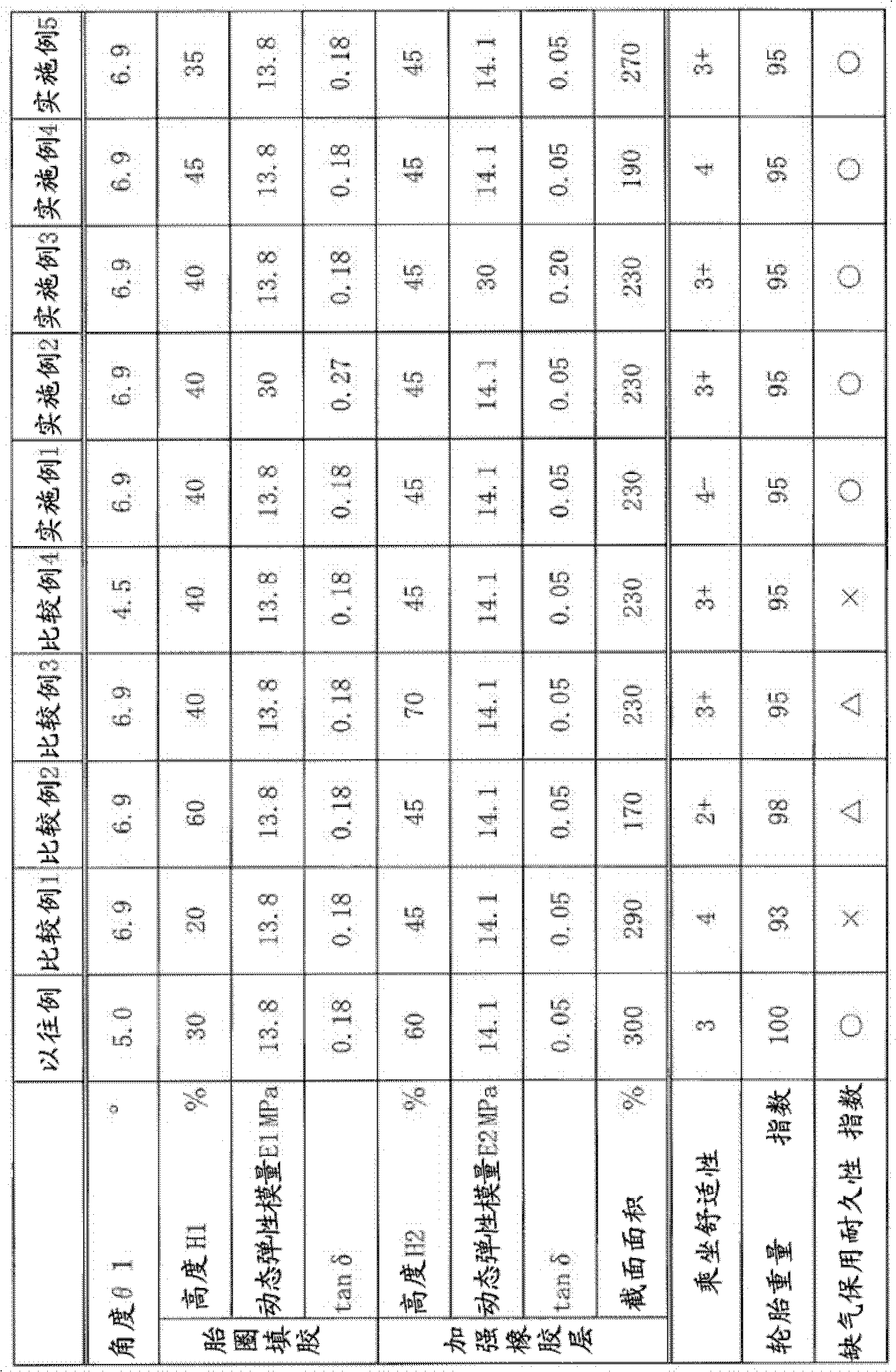

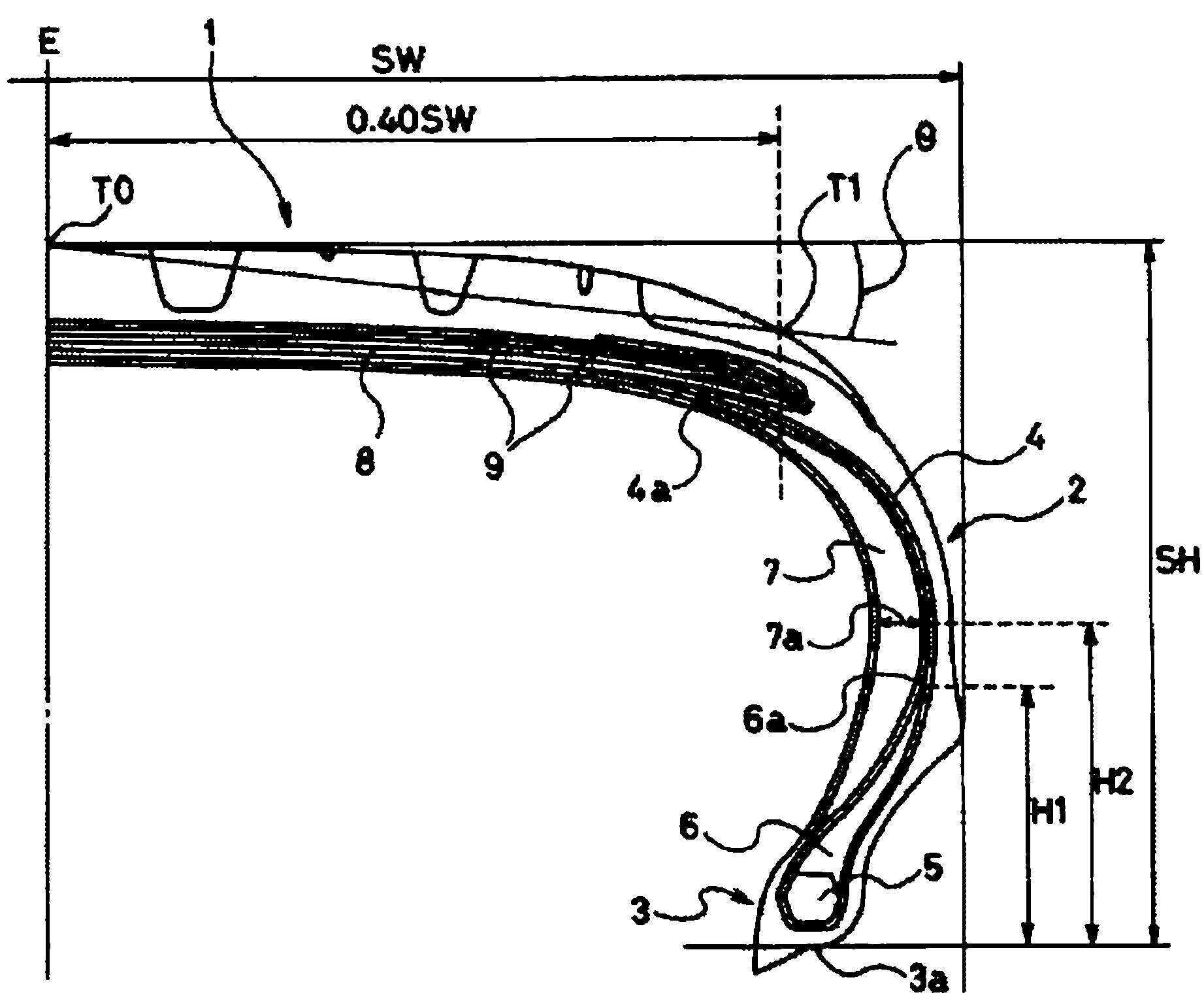

[0038] Ten types of conventional examples, comparative examples 1 to 4, and examples 1 to 5 were produced with the tire size set to 255 / 40RF19, and the specifications of the tire cross-sectional shape, bead filler, and reinforcing rubber layer as shown in Table 1. tire.

[0039] The conventional example is an example in which the angle θ and the height of the bead filler are smaller and the height of the reinforcing rubber layer is larger than the predetermined range of the present invention. Comparative Examples 1 and 2 are examples in which the height of the bead filler deviates from the range of the present invention. Comparative Example 3 is an example in which the height of the reinforcing rubber layer deviates from the range of the present invention. Comparative Example 4 is an example in which the angle θ deviates from the range of the present invention.

[0040] Examples 1 to 5 are all examples in which the cross-sectional shape of the tire is within the predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com