Automotive windshield wiper

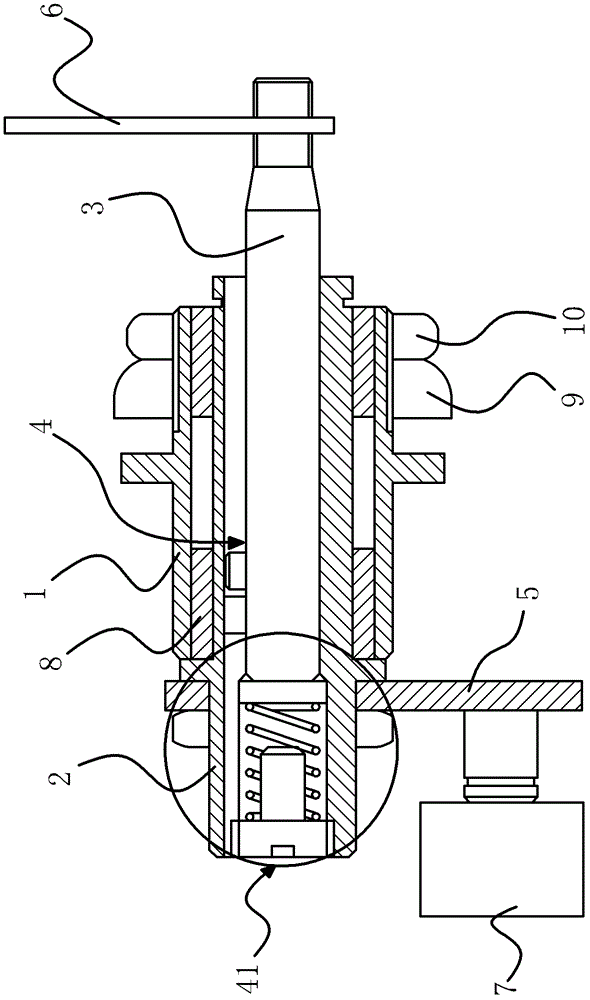

A wiper and automobile technology, applied in the field of automobiles, can solve the problems of inability to disassemble the scraper arm and wiper rod, and achieve the effect of complete and compact structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

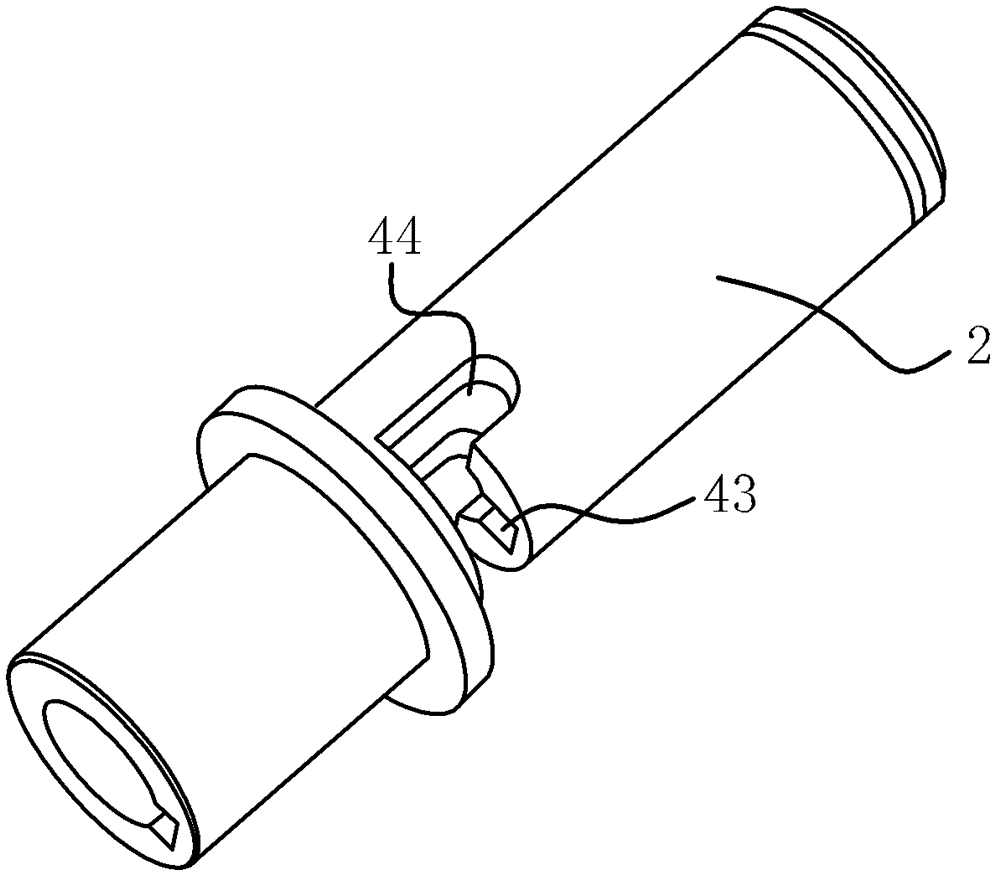

Examples

Embodiment 2

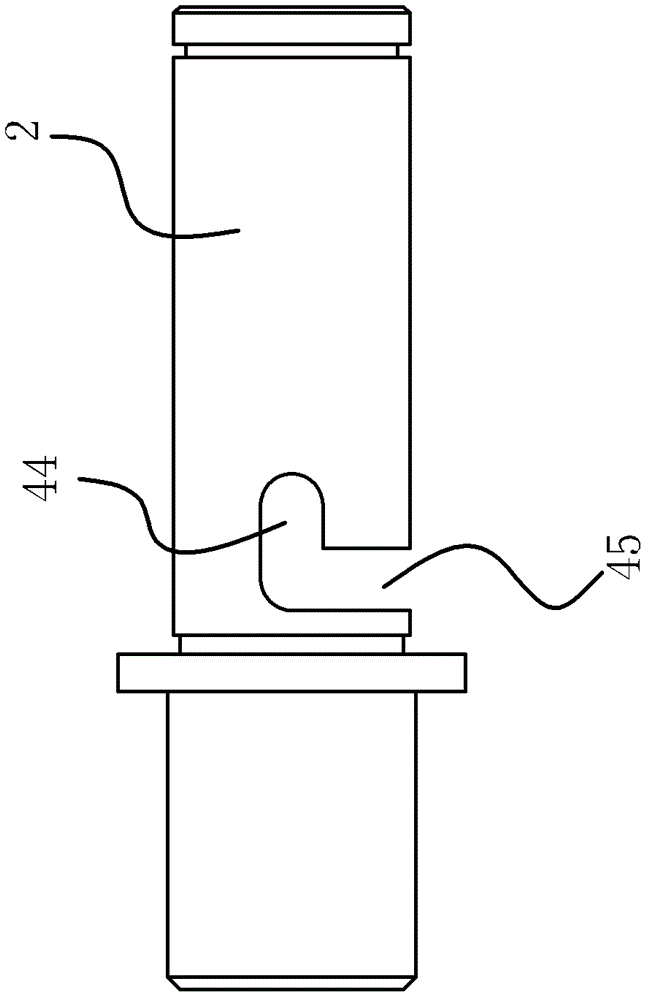

[0040] The structure of this automobile windshield wiper is basically the same as embodiment one, and the difference is that Figure 6 As shown, the supporting device 41 includes a spring seat 411 fixedly connected to one end of the hollow shaft 2, the spring seat 411 is threaded on the hollow shaft 2, and a spring 412 is arranged between the spring seat 411 and the rotating shaft 3. One end of 412 is fixed against the spring seat 411 to prevent the spring 412 from falling out when the rotating shaft 3 is pulled out, and the other end is against the above-mentioned rotating shaft 3 . The inner diameter of the section of the hollow shaft 2 where the spring 412 is placed is consistent with the inner diameter of the place where the rotating shaft 3 is inserted, so that the processing of the hollow shaft 2 is more convenient. The dismounting method of this automobile windshield wiper is identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com