Electric lifting control module surface paddle driving system and ship

A lifting control and drive system technology, applied in the field of boats, can solve the problems that affect the driving efficiency of surface paddles and cannot guarantee surface paddles, and achieve the effects of improving seaworthiness, adjusting sailing attitude, and increasing the buoyancy of boats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure of the surface paddle drive system of the electric lifting control module and the boat will be described in detail below in conjunction with specific embodiments and accompanying drawings, so as to make it more clear.

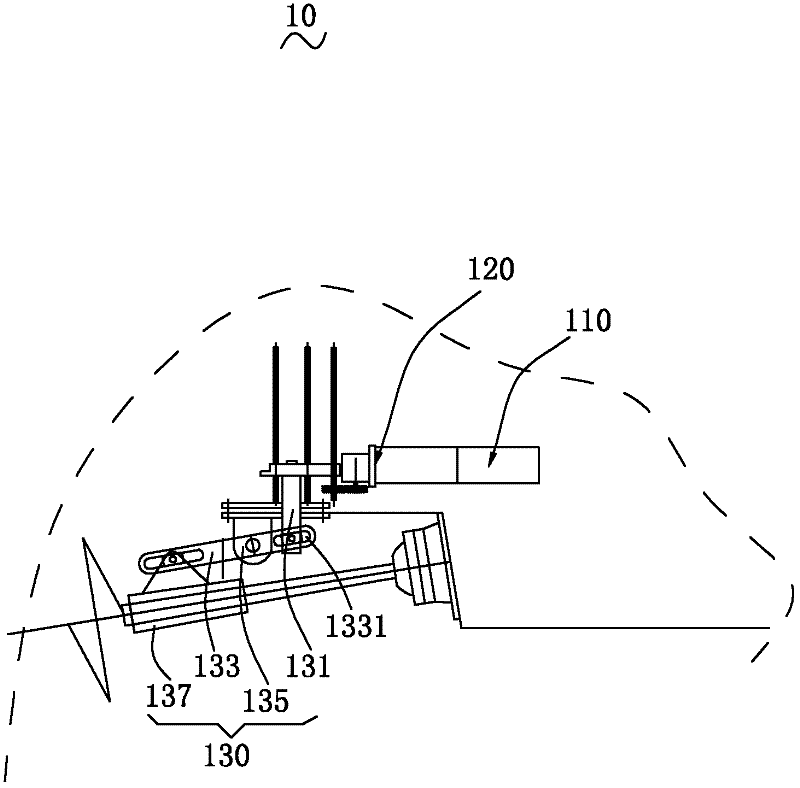

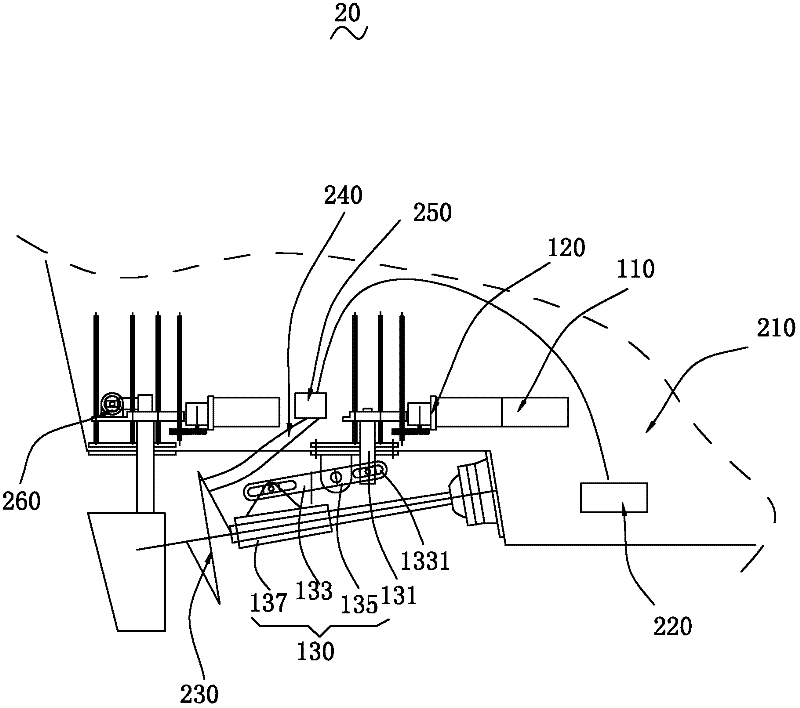

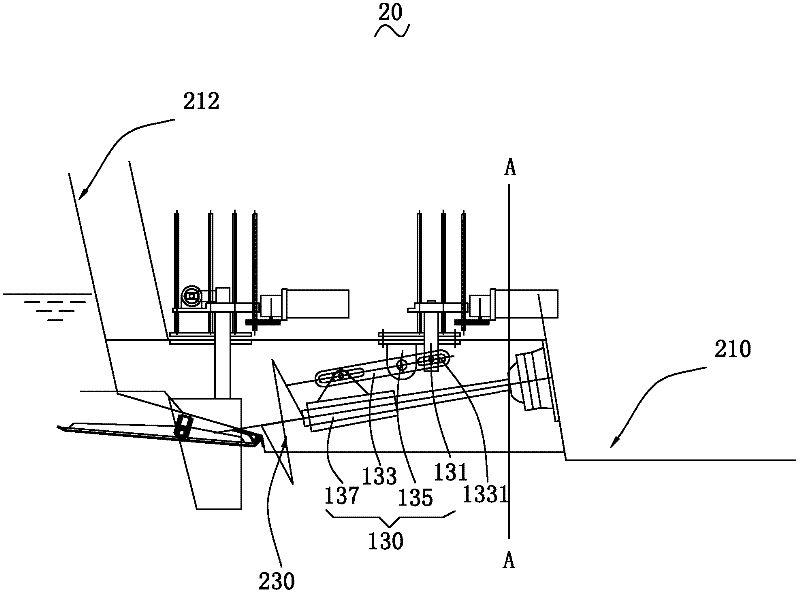

[0024] Such as figure 1 As shown, in one embodiment, an electric lift control module surface paddle drive system 10 is used to drive through the hull and is connected to the engine through a shaft, including a control device 110, a mechanical transmission device 120 and a transmission assembly 130 connected in sequence .

[0025] The control device 110 controls the operation of the mechanical transmission device 120 .

[0026] The mechanical transmission device 120 drives the transmission assembly 130 to work, and then drives the surface paddle to move up and down through the transmission assembly 130 to adjust the angle of the surface paddle. The mechanical transmission device 120 can obtain greater driving force with less power. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com